Lifting method, system and device for automatically adjusting tension of power transmission line

A transmission line, automatic adjustment technology, applied in transportation and packaging, load suspension components, electrical digital data processing, etc. Collision and other problems, to avoid manual control of lifting equipment, to achieve full automation control, to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

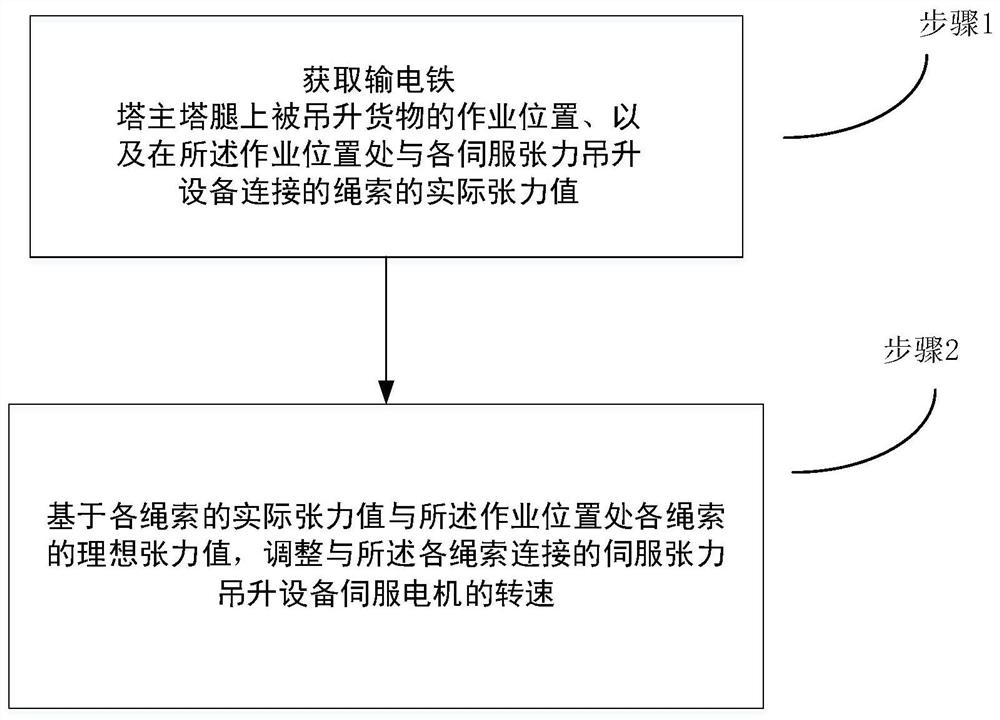

[0073] The invention discloses a hoisting method for automatically adjusting the tension of a transmission line, such as figure 1 shown, including:

[0074] Step 1: Obtain the operating position of the hoisted cargo on the main tower leg of the power transmission tower, and the actual tension value of the rope connected to each servo tension lifting device at the operating position;

[0075] Step 2: Based on the actual tension value of each rope and the ideal tension value of each rope at the working position, adjust the rotation speed of the servo motor of the servo tension lifting device connected to each rope;

[0076] The ideal tension value of the rope: based on the transmission tower information, the quality of the lifted goods, the working position of the lifted goods and the positions of the servo tension lifting equipment, it is calculated by using the lifting mechanics model.

[0077] Wherein, step 1: Obtain the operating position of the hoisted cargo on the main to...

Embodiment 2

[0087] A transmission line tension automatic adjustment lifting system in which each component can be disassembled and transported, and can be assembled quickly after arriving at the job site. The components here include various servo tension lifting equipment, multiple ropes, fixed structures and adjustment modules. Both mountainous and hilly areas can realize rapid motorized operations, without restrictions on operating terrain conditions.

[0088] The fixed structure is fixed on the top of the main tower leg of the transmission tower;

[0089] The number of servo tension lifting devices is the same as the number of ropes, and they are respectively connected correspondingly.

[0090] Each servo tension hoisting device at least includes: at least one first servo tension hoisting device and a plurality of second servo tension hoisting devices symmetrically arranged on both sides of the first servo tension hoisting device;

[0091] The rope connected to the first servo tension...

Embodiment 3

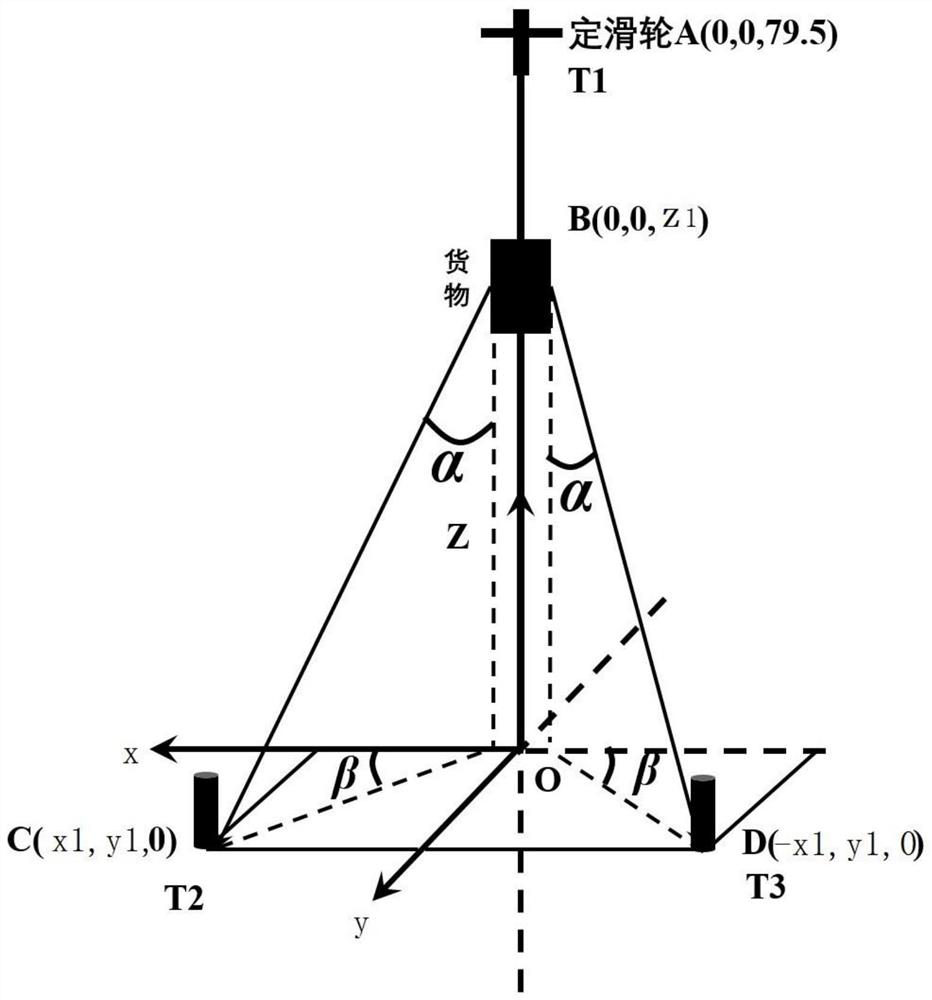

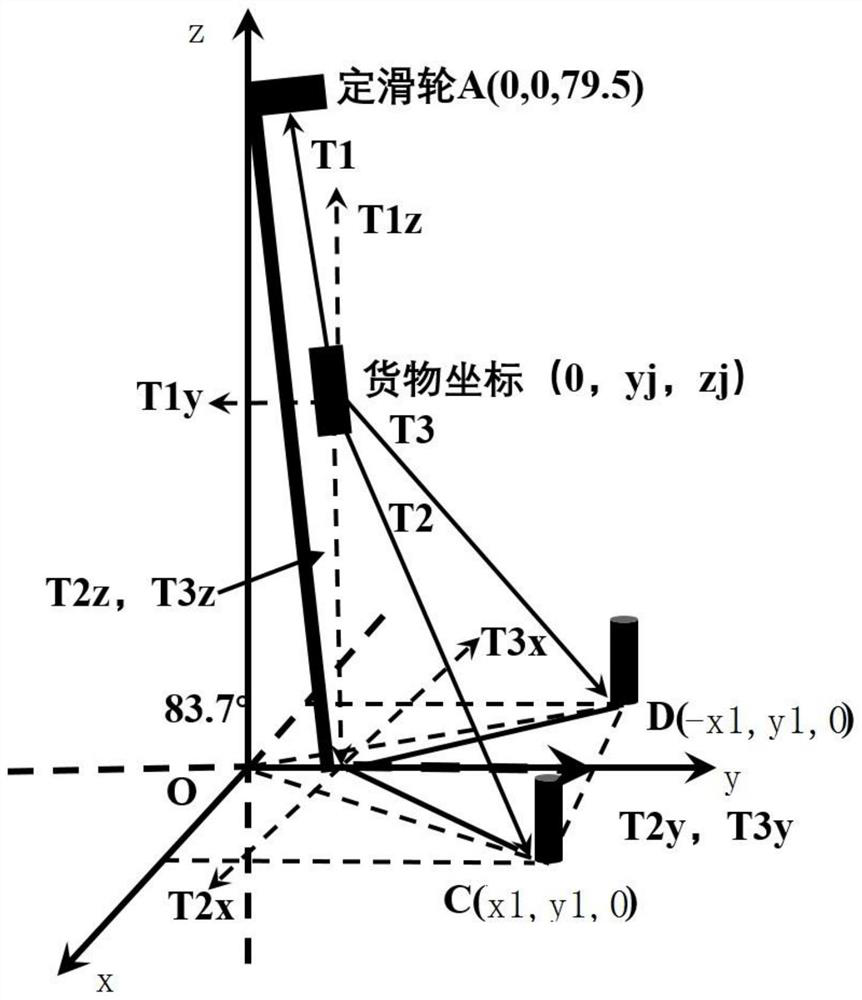

[0129] Taking three servo tension hoisting equipment as examples, we will introduce the construction of the hoisting mechanics model in detail, as follows: Figure 7 Shown:

[0130] The transmission line tower is composed of four main tower legs. When hoisting the hoisted goods, the hoisted goods are lifted based on one main tower leg in the iron tower, and the fixed pulley is located at the top of the main tower legs. , the angle between the main tower leg and the vertical line of the ground is 6.3°, as Figure 4 As shown, assuming that the length of the main tower leg is 80m, the tensions generated by the three-rope hoisting are T1, T2, and T3 respectively. device) connected by the rope, which mainly plays the role of hoisting. The tensions T2 and T3 are provided by ropes connected to the second servo tension hoist (ie, the left servo tension pulling device and the right servo tension pulling device) located symmetrically on both sides of the first servo tension hoisting d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com