Gravure electronic engraving machine equipment built-in intelligent temperature control equipment

An electronic engraving, intelligent temperature control technology, applied in the field of engraving machines, can solve the problems of increasing equipment use limitations, easy to generate backflow, reducing heat dissipation efficiency, and temperature control work stability and accuracy, to suppress frequent startup and energy consumption. Consumption, Sustainability and Stability Improvements, Increased Multi-stage Processing Efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

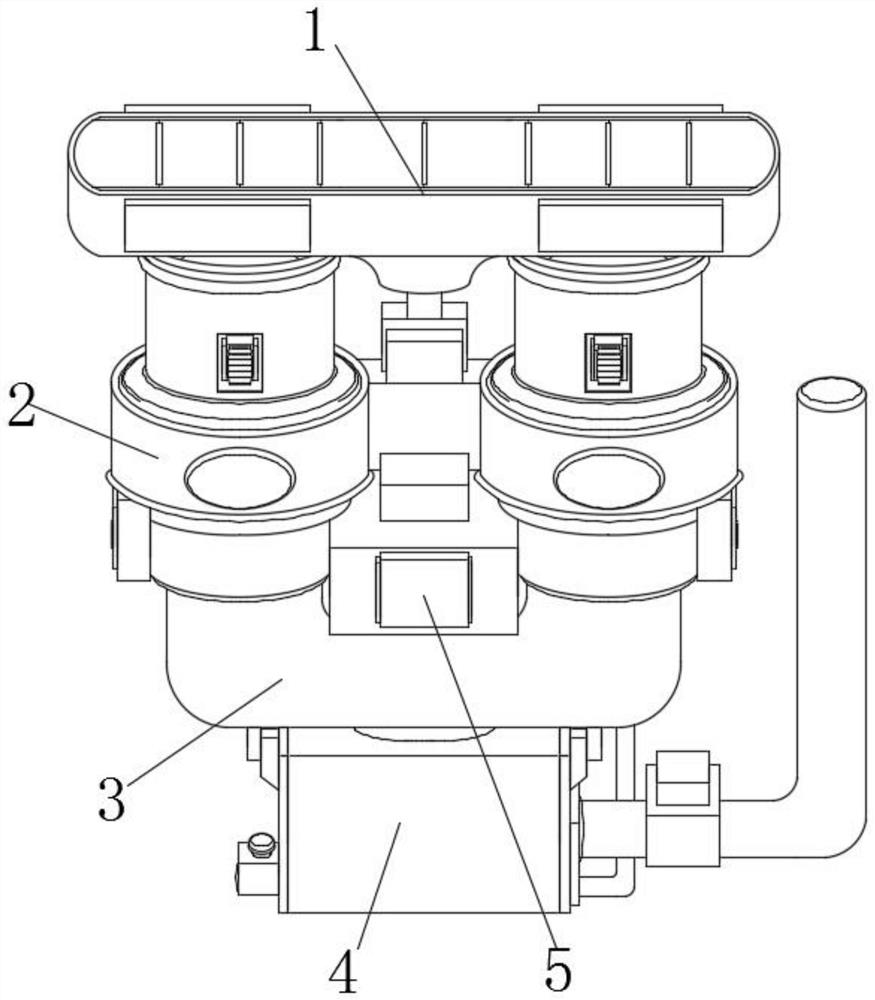

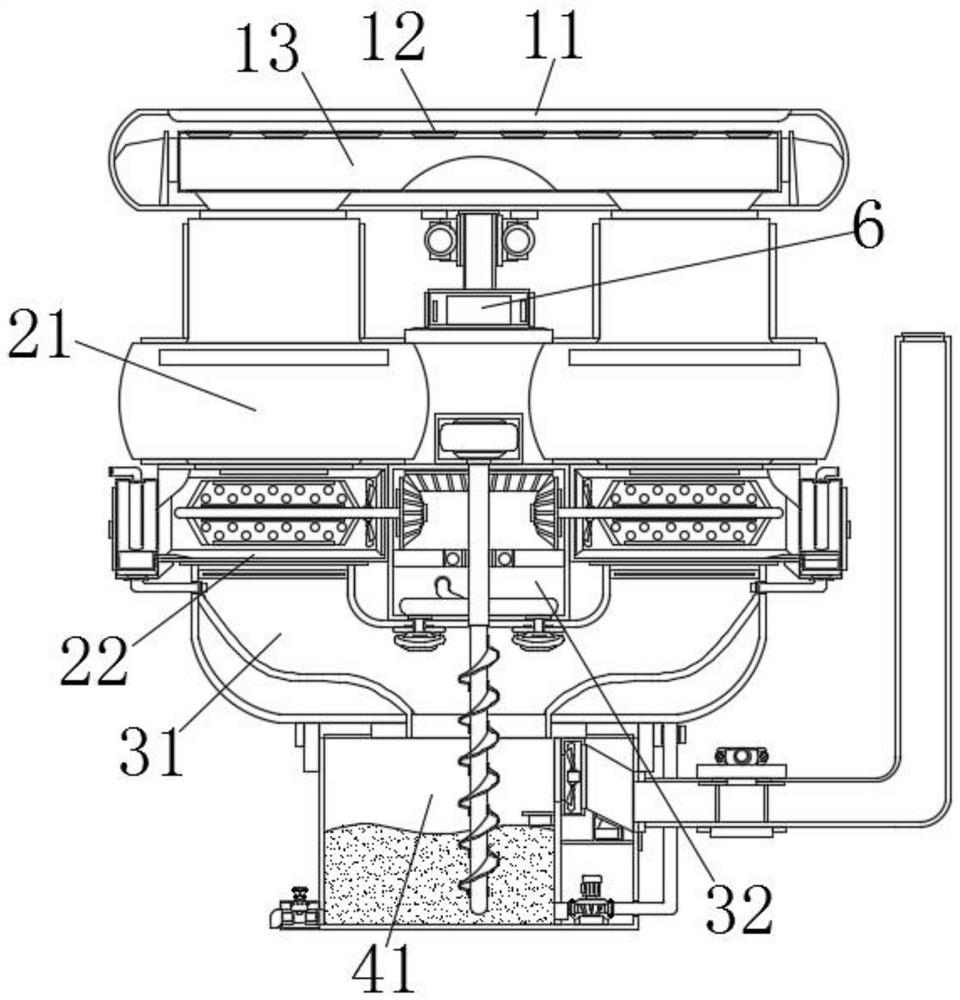

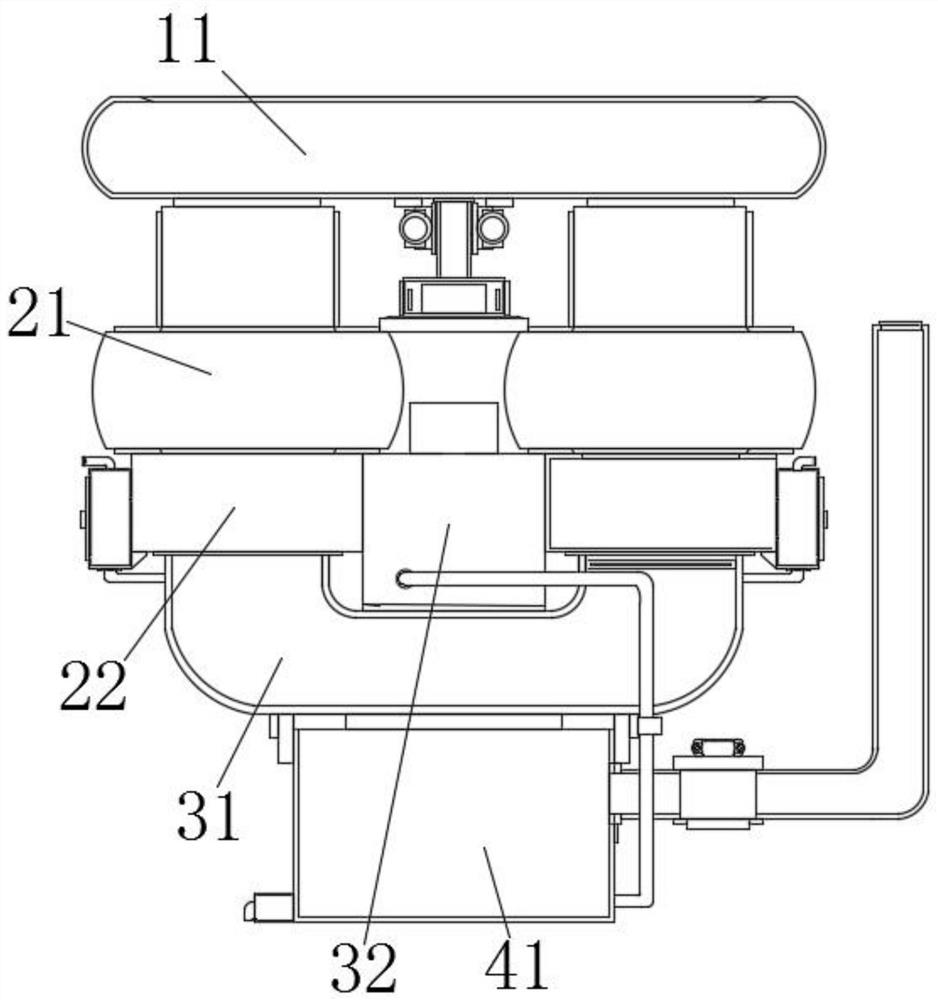

[0043] Example 1, as Figure 1-4 As shown, when the two sets of suction fans 21 are activated, the heat source gas and dust in the body can be sucked into the air guide groove 22 together, and the gas is divided and guided by the rotation of the fan blades 34 and the stirring blades 33. , and the installation of the filter screen plate prevents the dust from entering the U-shaped air duct 31, and promotes the dust to enter the communication groove 393 under the guidance of the rotation of the stirring blade 33 and the fan blade 34. At this time, the entering dust can be passed through the water curtain 392. Adsorption and gas separation and filtration are performed, and the adsorbed dust can adhere to the surface of the water curtain 392 or fall into the filter tank 391, which is convenient for subsequent processing work.

Embodiment 2

[0044] Example 2, as Image 6 As shown in the figure, during the guidance and separation of dust and gas through the air guide groove 22 and the absorption filter system 39, the water can be injected into the water curtain 392 through the water inlet pipe to promote the surface of the water curtain 392 to seep water. The flowing gas assists in cooling, and at the same time, the dust adhering to the surface of the water curtain 392 is discharged, so that the dust is uniformly dropped into the filter tank 391 for collection, and the operability and convenience of the subsequent cleaning work of the structure are increased.

[0045] Working principle: When the equipment is in use, first install the device inside the electronic engraving machine, and then use the temperature monitor 6 to intelligently monitor the temperature control in the body. When the temperature gradually rises beyond the specified index with the start of the body, The suction fan 21 can be automatically activ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap