Novel packer

A packer and a new type of technology, applied in the directions of sealing/packing, wellbore/well components, earth-moving drilling, etc., can solve the problems of high safety hazard, damage and failure of the rubber cylinder group, etc., to alleviate the use strength, prolong the Long service life and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

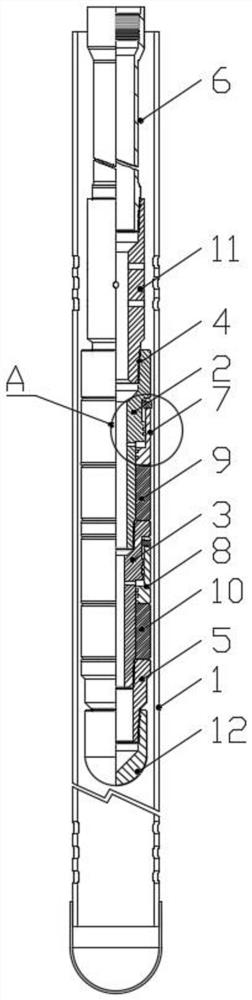

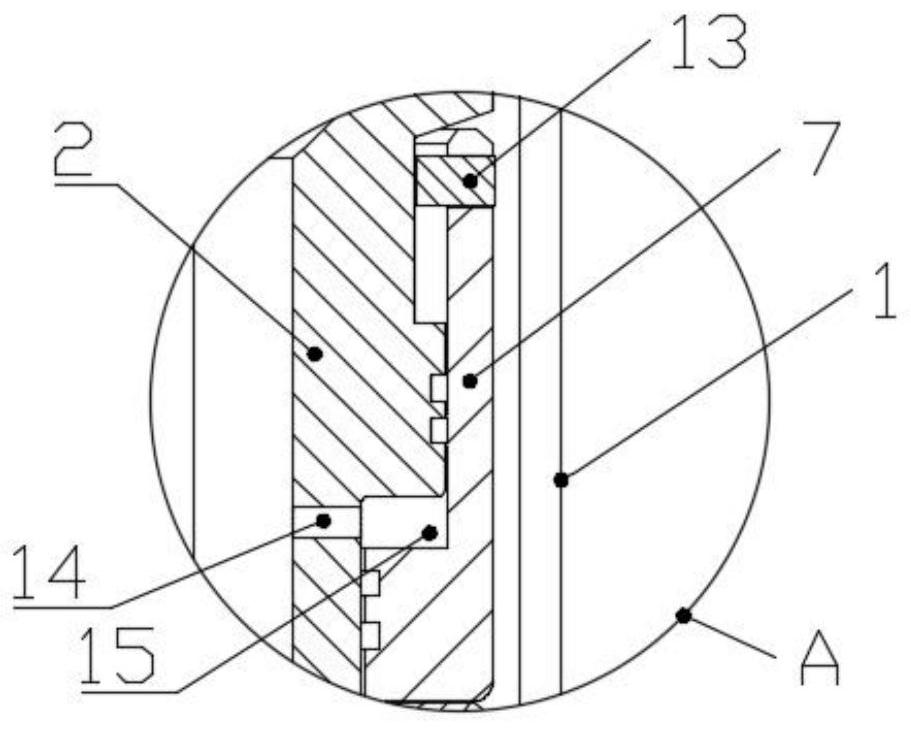

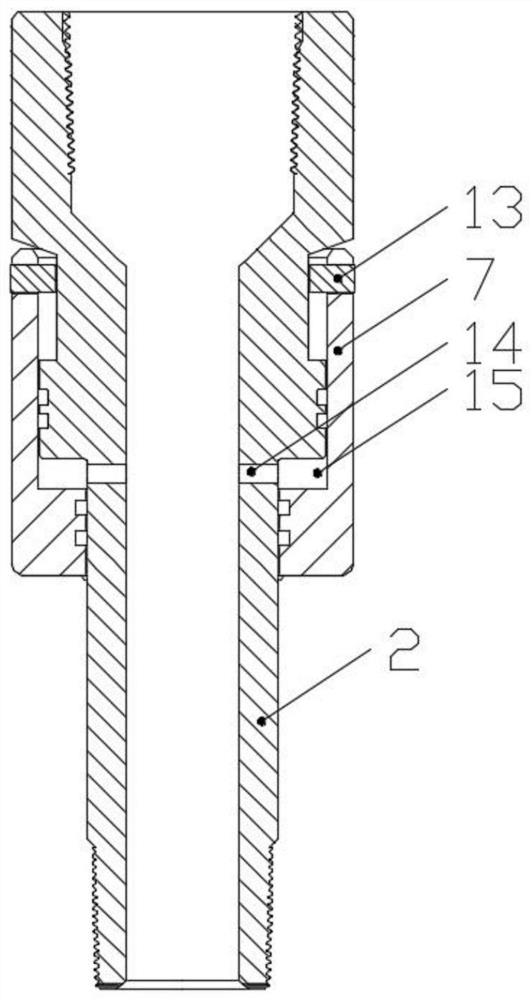

[0021] Such as Figure 1-3 As shown, the present invention is a new type of packer, the new type of packer is installed in the casing 1, the new type of packer includes an upper center pipe 2, and the outer side of the upper center pipe 2 is sequentially arranged from top to bottom The upper rubber tube drive ring 7 and the upper rubber tube 9 are sleeved, and the outer bottom end of the upper central tube 2 is provided with a connecting thread, and is connected with the lower central tube 3 through the connecting thread, and the outer side of the lower central tube 3 is formed by the upper The lower rubber tube drive ring 8 and the lower rubber tube 10 are sequentially set on the bottom. The outer side of the bottom end of the lower central tube 3 is provided with a connecting thread, and the lower joint 5 is connected to the lower joint 5 through the connecting thread, and the bottom of the lower joint 5 The outside of the end is provided with a connecting thread, and is con...

Embodiment 2

[0027] When the novel packer of the present invention is in use, it is necessary to ensure that the flow direction of the fracturing fluid in the annular space of the tubing 6 and casing 1 is the same as that of the upper rubber casing drive ring 7 and the lower rubber casing driving ring 8. 1 The kinetic energy in the fracturing fluid realizes auxiliary setting, and can achieve power without additional mechanical components, and provides a force in the same direction for the sealed rubber cartridge group, which can further increase the effective setting force and make the rubber The cartridge setting is tighter (if the direction of movement of the driving ring of the cartridge is opposite to the direction of the fracturing flow, the setting and sealing performance of the cartridge will be greatly weakened), the sealing performance is increased, and it is tightly leak-proof;

[0028] The double power chambers are installed independently in series, requiring the upper rubber cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com