A free-loading single-chamber double-push solid small rocket structure

A small rocket and loading technology, which is applied in the direction of rocket engine devices, jet propulsion devices, machines/engines, etc., can solve problems such as debonding of the grain-column joint surface and deviation of engine performance, so as to improve launch reliability and ignition reliability Sexuality, beneficial to ignition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

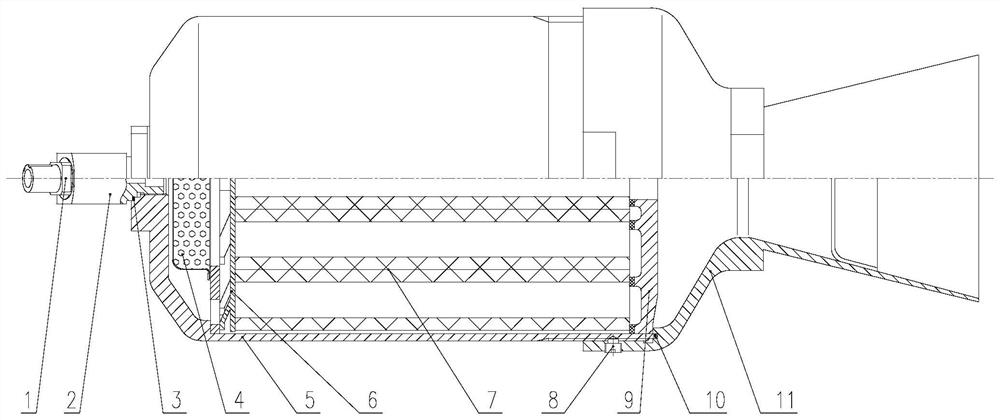

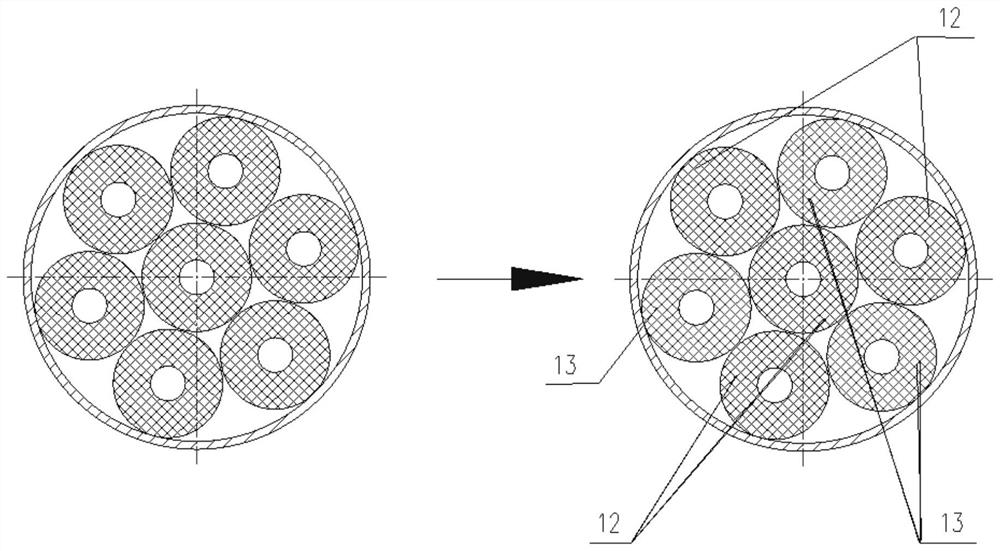

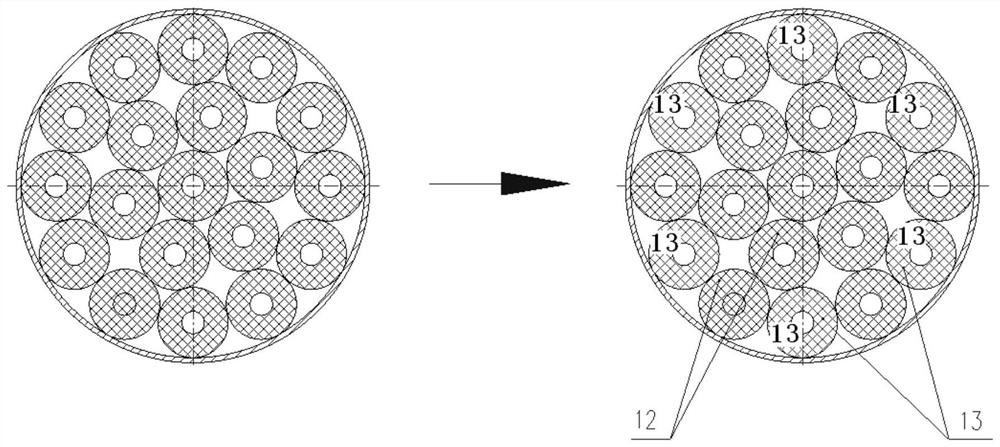

[0079] The double-base system grain is used to carry out a free-packing design. There is no fixed interface between the grains, which can completely avoid the problem of interface debonding between the grains with different burning rates. The typical free-packing solid small rocket structure is shown in figure 1 . When the two grains are mixed, by adjusting the distribution and quantity of the high-burning rate grains, different thrust-time curve combinations can be formed according to the design requirements, and different speed-time curve combinations can be formed when acting on the target. The high-burning velocity grains finish work before the low-firing velocity grains. In order to avoid unbalanced influence on the internal ballistics, their distribution should be symmetrical and uniform. When 7 grains are charged, the typical high burning rate grain arrangement structure is shown in figure 2 , when 19 grains are charged, the typical high burning rate grain arrangement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com