Magneto-rheological clutch with driving disc of groove structure

A transmission disk and magneto-rheological technology, applied in the direction of fluid clutches, clutches, couplings, etc., can solve the problems of increased energy consumption and temperature rise, and achieve the effects of increasing torque transmission, reducing the maximum temperature rise, and enhancing heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

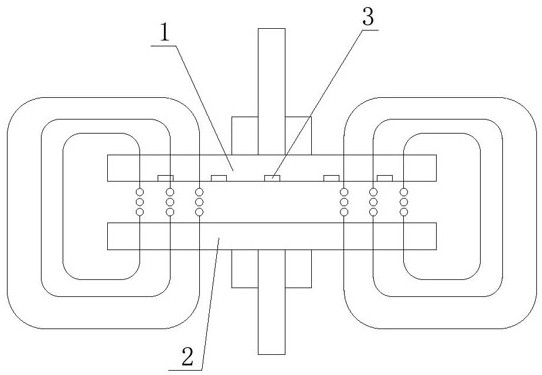

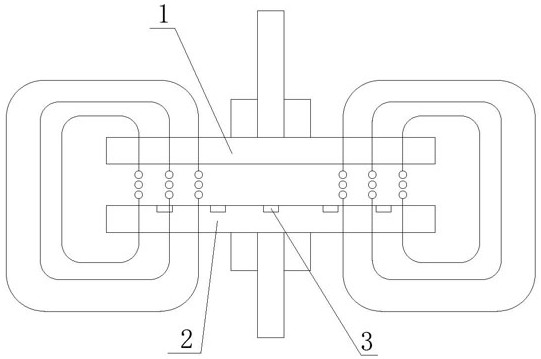

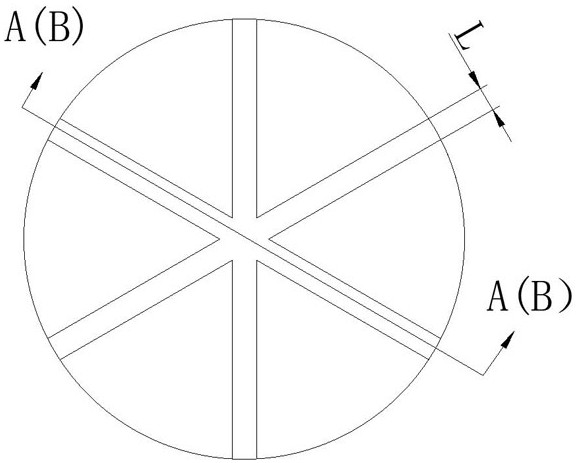

[0039] like image 3 and 4 As shown, the groove 3 is an elongated radial groove extending from the center of the main transmission disc 1 or from the center of the transmission disc 2 along its radial direction, and the number of the elongated radial grooves is at least three , the optimal number of strips is 4-12; the radial grooves are uniformly distributed on the inner surface of the main transmission disc 1 or the secondary transmission disc 2 along the circumferential direction at equal angles. The radial grooves are elongated grooves with equal width, and the width of the radial grooves is 4-10mm. The depths of the radial grooves are equal, and the depth of the radial grooves is 1-5 mm.

[0040] Trench Structure Second Embodiment

[0041] like image 3 and 5 As shown, the groove 3 is an elongated radial groove extending from the center of the main transmission disc 1 or from the center of the transmission disc 2 along its radial direction, and the number of the elon...

no. 5 example

[0047] like Figure 7 and 9 As shown, the grooves 3 are concentric annular grooves distributed at equal intervals along the radial direction from the center of the main transmission disc 1 or the transmission disc 2, and the center-to-center distance of adjacent annular grooves ranges from 10 to 40 mm. The widths of the annular grooves are equal, and the width of the annular grooves is 4-10mm. The depth of the annular groove is reduced one by one by the depth of the outer annular groove of the inner ring, the range of the depth of the annular groove is 1-5mm, and the variation of the depth of the annular groove is the maximum difference of the depth of the annular groove The value is divided by the number of ring slots.

[0048] The sixth embodiment of trench structure

[0049] like Figure 10 and 11 As shown, the grooves 3 are concentric annular grooves distributed at equal intervals along the radial direction from the center of the main transmission disc 1 or the transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com