Anti-permeability environment-friendly resin concrete slump detection device

An environmentally friendly resin and detection device technology, which is applied in the direction of measuring devices, material inspection products, instruments, etc., can solve the problems of prone to deviation in action, affecting measurement accuracy, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

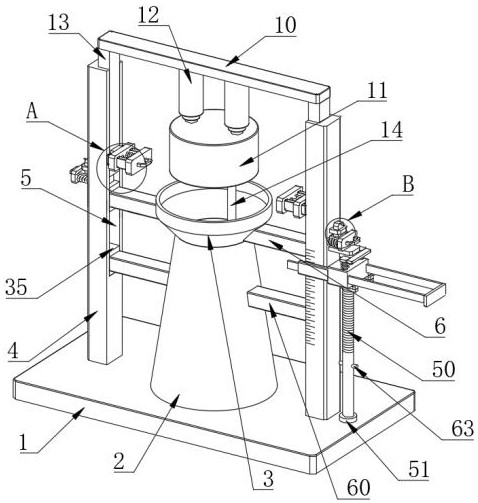

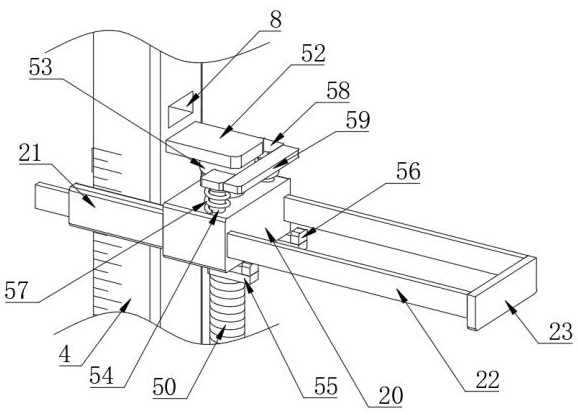

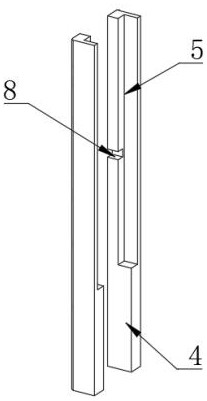

[0033] Embodiment one, by Figure 1 to Figure 8 Given, the present invention comprises operating platform 1 and slump cylinder body 2, and slump cylinder body 2 is arranged on the top of operating platform 1, and the top of slump cylinder body 2 is provided with funnel body 3, and the top of operating platform 1 There are two supporting side plates 4 fixedly connected, and the two supporting side plates 4 are respectively located on both sides of the slump cylinder body 2, and the sides close to each other of the two supporting side plates 4 are provided with a first chute 5, the second The top inner wall of a chute 5 communicates with the top of the supporting side plate 4, and the funnel body 3 is fixedly connected with two first connecting columns 6, and one end of the first connecting column 6 is fixedly connected with a first slider 7, and the second A slider 7 is located in the first chute 5, and the slump cylinder body 2 is fixedly connected with two second connecting c...

Embodiment 2

[0035] Embodiment two, on the basis of embodiment one, by Figure 7 and Figure 8 Given, the rotating assembly includes a first fixed shaft 24 arranged on the top of the rotary adjustment disc 15, the top of the first fixed shaft 24 is fixedly connected to the top inner wall of the control box 11, and the bottom end of the first fixed shaft 24 is connected to the top of the rotary adjustment disc 15. The top of the top is connected by the second bearing 25, the first fixed shaft 24 is sheathed with the first bevel gear 26, one side of the first bevel gear 26 is provided with the second bevel gear 62, the second bevel gear 62 One side of the second fixed shaft 28 is fixedly connected with a second fixed shaft 28, and one side of the second fixed shaft 28 is provided with a first fixed plate 27, and the bottom of the first fixed plate 27 is fixedly connected with the top of the rotary adjustment disc 15, and the second fixed shaft 28 One end of one end is connected with one sid...

Embodiment 3

[0037] Embodiment three, on the basis of embodiment one, by figure 1 , Figure 4 and Figure 5 Given, the pressing assembly includes a second fixing plate 37 arranged on one side of the slide bar 13, one side of the second fixing plate 37 is connected to one side of the slide bar 13 through a connecting block 38, and the second fixing plate 37 is far away from the connecting block 38 One side of the first movable plate 36 is provided with a first movable plate 36, and the side of the first movable plate 36 close to the second fixed plate 37 is fixedly connected with two positioning pressing plates 39, and one end of the positioning pressing plate 39 passes through the second fixed plate 37, the second One side of a movable plate 36 is connected with one side of the second fixed plate 37 by some first tension springs 40; the side of the positioning pressing plate 39 away from the first movable plate 36 is fixedly connected with an anti-skid pad 41, and the anti-skid pad 41 On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com