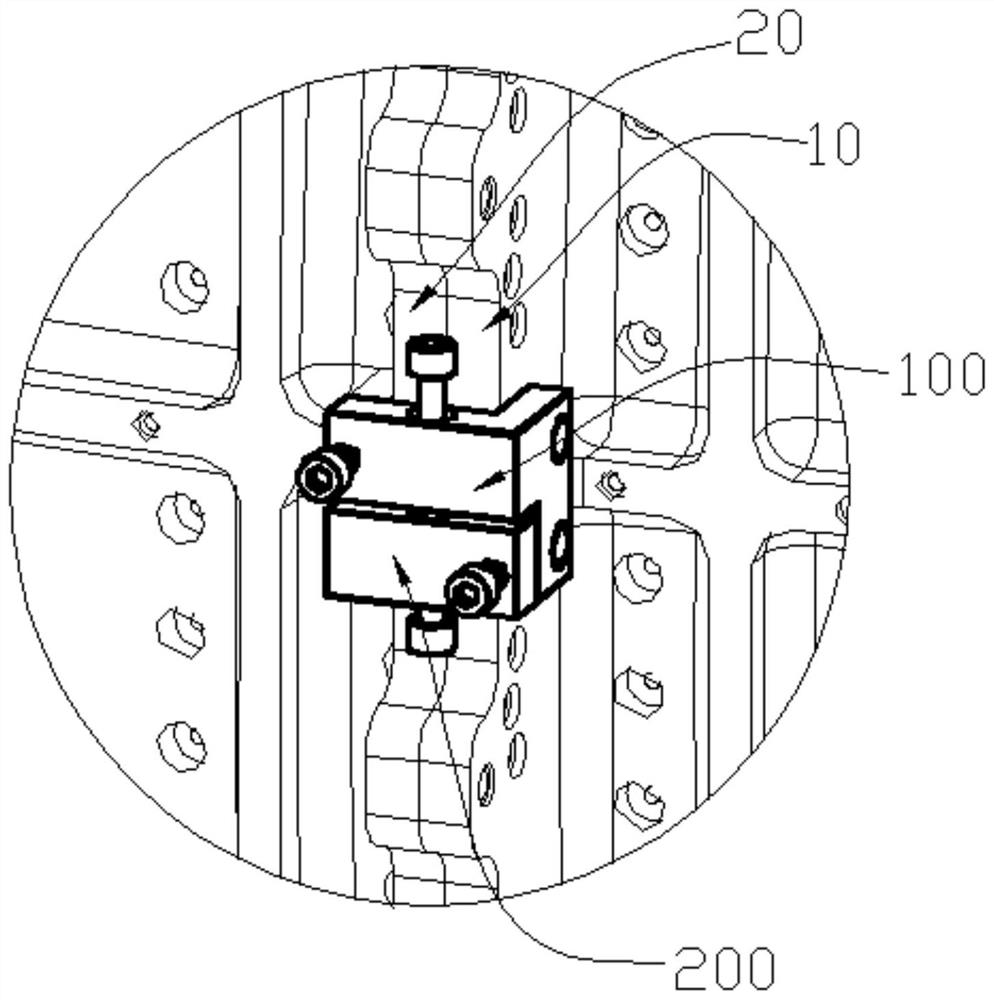

Dislocation adjusting device for cylinder combination

An adjustment device and a technology for combining cylinders, which is applied in the field of misalignment adjustment, can solve problems such as the misalignment of combining cylinders, and achieve the effects of avoiding workpiece distortion, convenient disassembly, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

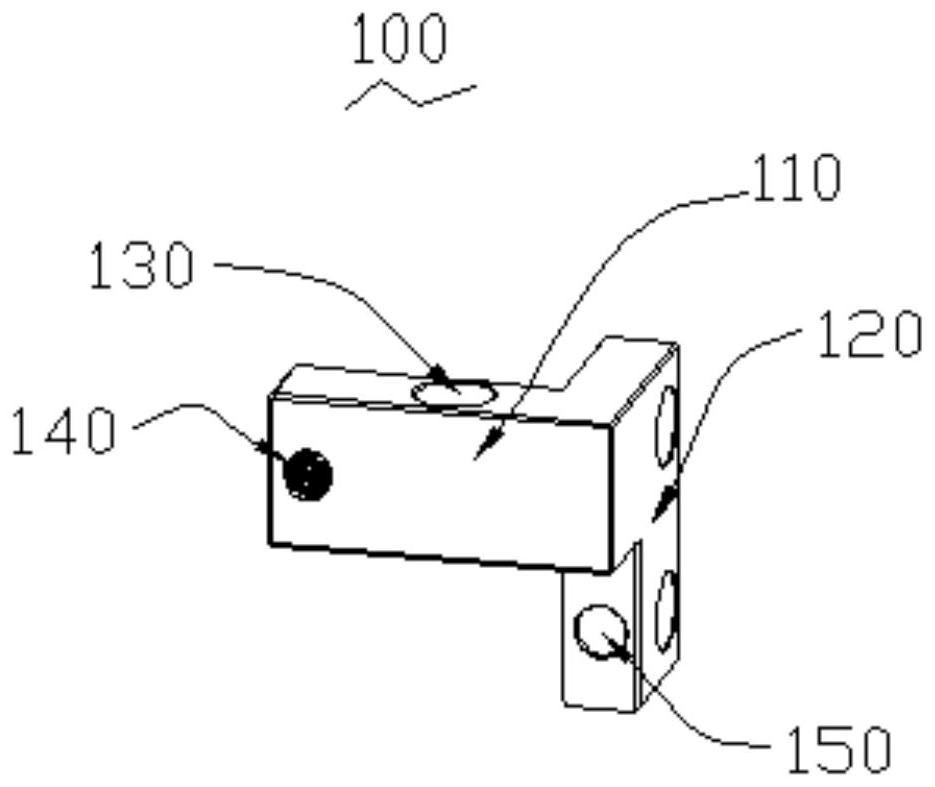

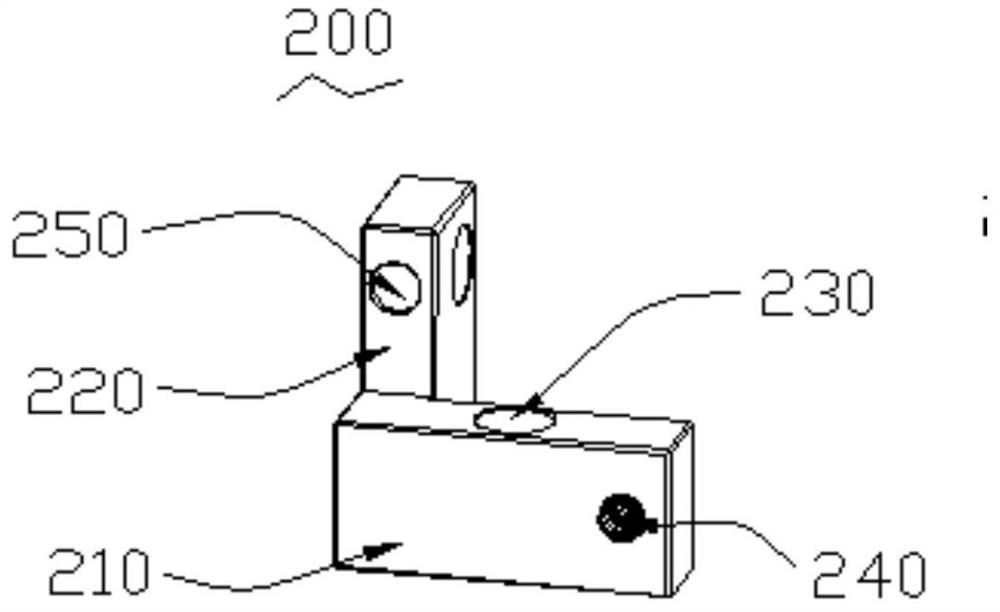

[0027] Embodiment 1, on the basis of the structure described above, the first section 110 is provided with a through hole 130 along the second direction, the third section 210 is provided with a threaded through hole 2 230 along the second direction, and the through hole 130 is Coaxial with the threaded through hole 2 230 , the screw 1 400 passes through the through hole 130 and passes through the threaded hole 2 230 , and the first section 110 and the third section 210 are approached by screwing the screw 1 400 .

[0028] When the position of the installation hole of the first casting 10 is higher than the installation hole of the corresponding second casting 20, the screw rod one 400 passes through the through hole one 130 and is passed in the threaded hole two 230, and the screw rod one 400 is screwed to make The first section 110 is close to the third section 210, that is, the third section 210 rises close to the first section 110, so that the second casting 20 rises, so th...

Embodiment 2

[0029] Embodiment 2, on the basis of Embodiment 1, the end of the through hole 130 opposite to the third section 210 is set as a counterbore 111, and a supporting gasket 800 is arranged in the counterbore 111, and the outer diameter of the supporting gasket 800 is larger than The inner diameter of through hole one 110 is smaller than the inner diameter of counterbore one 111, so that support pad 800 can block through hole one 130 and play the role of blocking screw rod 500; screw rod two 500 is installed in threaded through hole two 230 and the support pad The sheet 800 is in contact, and the first segment 110 is separated from the third segment 210 by screwing the screw 2 500 .

[0030] When the position of the mounting hole of the first casting 10 is lower than the mounting hole of the corresponding second casting 20, the screw 2 500 passes through the threaded hole 230 and contacts the support washer 800, and the second screw 500 is screwed to make the second One section 11...

Embodiment 3

[0031]Embodiment three, on the basis of embodiment two, the first section 110 is provided with a threaded through hole three 140 interlaced with the through hole one 110, and the threaded through hole three 140 is arranged at an end far away from the second section 120; the screw rod three 600 passes through Set in the threaded through hole 3 140, and contact with the end face of the fourth section 220, the first section 110 and the fourth section 220 are separated by screwing the screw 3 600; wherein in order to accurately locate the position of the screw 3 600, the fourth section 220 A blind hole 1 230 is provided at a position matched with the screw 3 600 .

[0032] When the position of the mounting hole of the first casting 10 is behind the corresponding mounting hole of the second casting 20, thread the screw three 600 through the threaded through hole three 140 and place it in the blind hole one 230, and screw the screw Three 600 make the first section 110 and the fourth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com