Hydraulic control tubular column storage system

A storage system and pipe string technology, which is applied to drill pipes, casings, drilling equipment, etc., can solve the problems of inconvenient storage and removal of drill pipes, low safety and reliability, and inaccurate control, so as to increase overall safety. and reliability, quick installation and improved transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

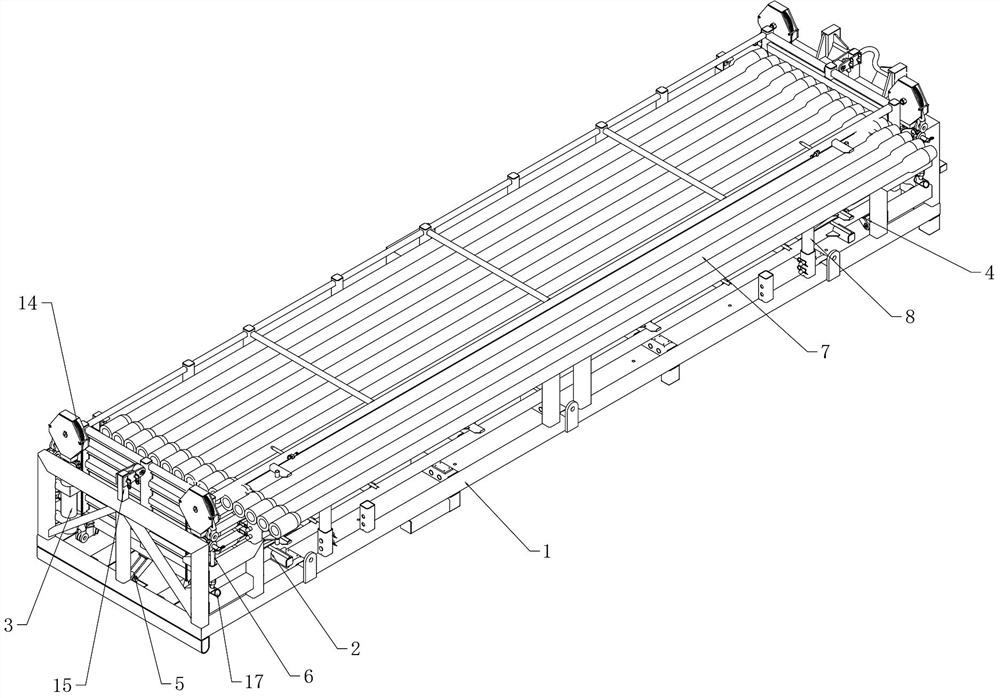

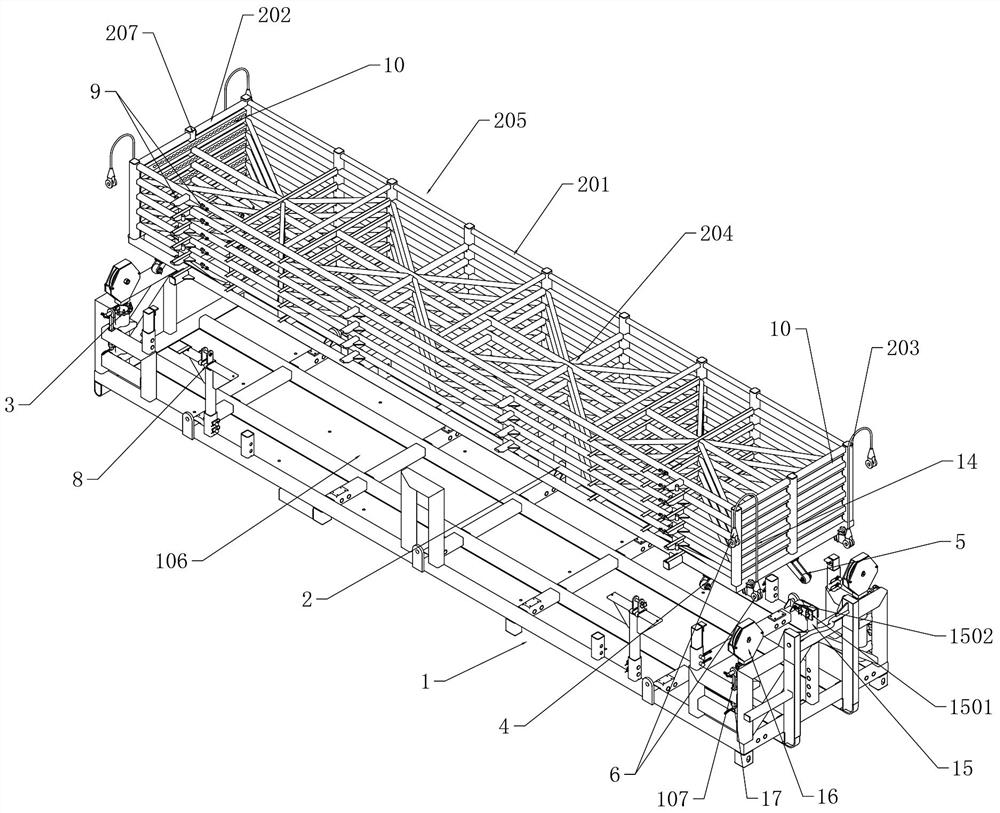

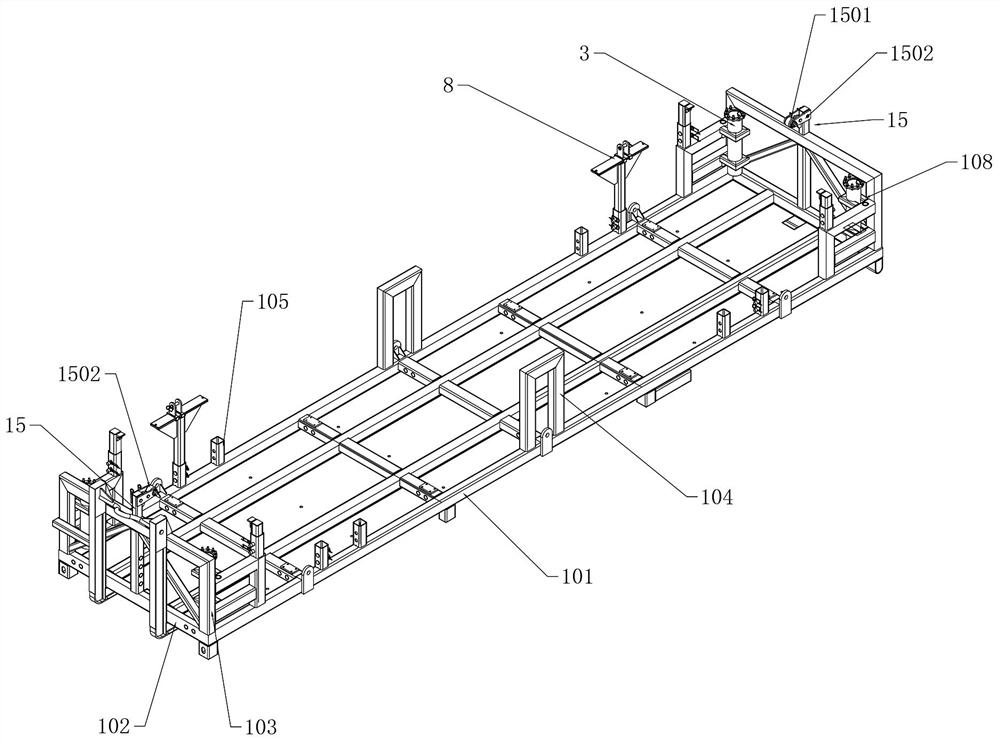

[0034] Such as Figure 1-10 Among them, a liquid control column storage system includes an outer box body 1 and an inner box body 2, the inner box body 2 is detachably arranged in the outer box body 1, and two first Guardrail 103, the inner side of first guardrail 103 is respectively symmetrically provided with two hydraulic cylinders 3, and hydraulic cylinder 3 is provided with jacking guide wheel 16, and jacking guide wheel 16 is connected with inner box body 2 by wire rope 14, and the first The upper middle position of the guardrail 103 is also provided with a limit column 15 , and the outer side of the inner box body 2 is oppositely provided with two positioning rollers 5 , and the positioning rollers 5 are slidably arranged on the first guardrail 103 . The lower side of the jacking guide wheel 16 is also provided with an adjustment screw 17, so that under the drive of the hydraulic cylinder 3, the wire rope 14 can drive the inner box body 2 to lift from the inside of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com