Impeller auxiliary structure for overspeed test of cantilever centrifugal expanderimpeller

A centrifugal expansion and auxiliary structure technology, applied in the field of expanders, can solve the problems of large impeller vibration, heavy impeller monomer, affecting the normal progress of the overspeed test, etc., and achieves the effect of reducing vibration, convenient assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

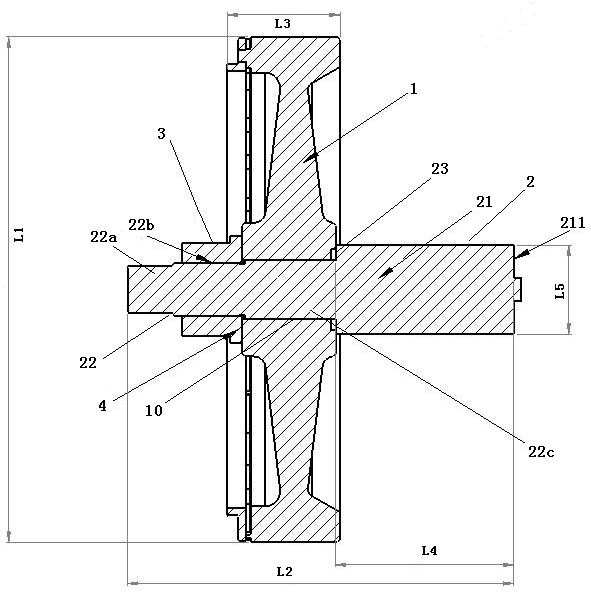

[0014] Please refer to figure 1 . The impeller auxiliary structure of the impeller overspeed test of the cantilever centrifugal expander according to the embodiment of the present invention includes an impeller 1 , an auxiliary shaft 2 , a lock nut 3 and a gasket 4 .

[0015] The impeller 1 is the impeller of a cantilever centrifugal expander that needs to be subjected to an overspeed test.

[0016] The auxiliary shaft 2 is a stepped shaft, which includes a first shaft section 21 with a larger outer diameter and a second shaft section 22 with a smaller outer diameter, and a shoulder is formed between the first shaft section 21 and the second shaft section 22 23 , the shaft shoulder 23 abuts against the rear end of the impeller 1 . The second shaft section 22 passes through the central hole 10 of the impeller 1, the lock nut 3 and the washe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com