Flexible job shop scheduling method based on improved wolf pack algorithm

A flexible job, workshop scheduling technology, applied in computing, computing models, manufacturing computing systems, etc., can solve the problem of inability to accurately measure the similarity distance between individual codes of discrete flexible job shops, difficulty in building a flexible job shop production scheduling model by wolf pack algorithm, The global search ability is not strong enough to achieve the effect of enhancing the global search ability, balancing exploration ability and mining ability, and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

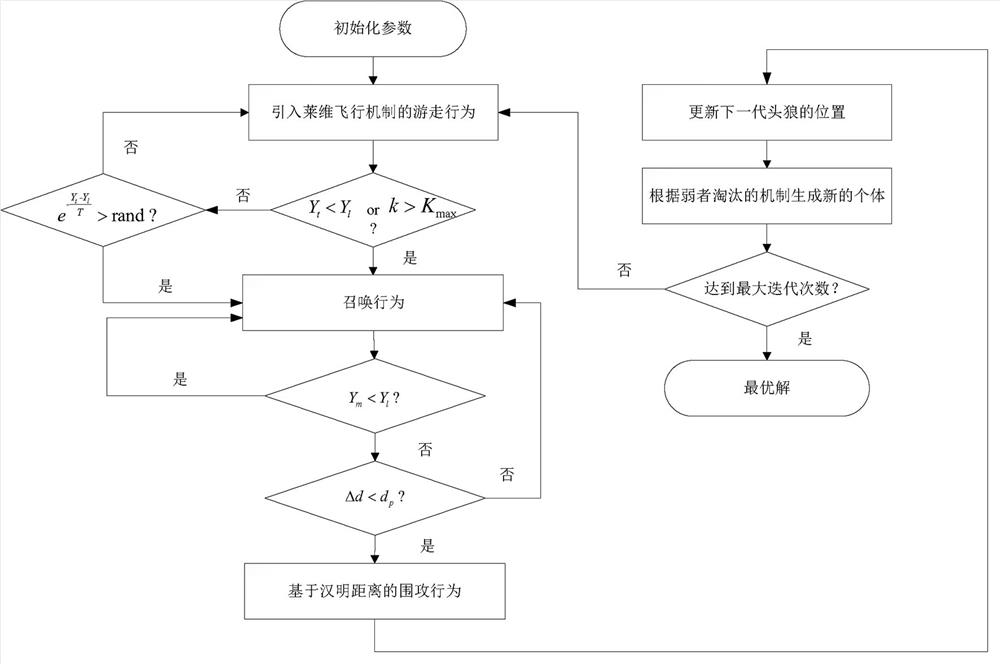

[0066] like figure 1 As shown, a flexible job shop scheduling method based on the improved wolf pack algorithm includes the following steps:

[0067] Step 1: Initialize parameter settings. The parameters include: the total number of wolf pack individuals N, the number of algorithm iterations M, the wolf detection scale factor α, the siege distance discrimination factor ω, and the maximum number of wolf detection walks K max , step size factor S, group elimination scale factor β, number of wolf detection directions h, initial temperature T in simulated annealing algorithm 0 , Attenuation factor γ;

[0068] Specifically, the total number of wolves in the example is N=60, the number of algorithm iterations M=100, the wolf detection scale factor α=6, the siege distance discrimination factor ω=10, and the maximum number of wolf detection K max =100, step s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com