Current interrupter system

A technology of current breaker and circuit breaker, which is applied in the field of current circuit breaker system and can solve problems such as economic balance burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

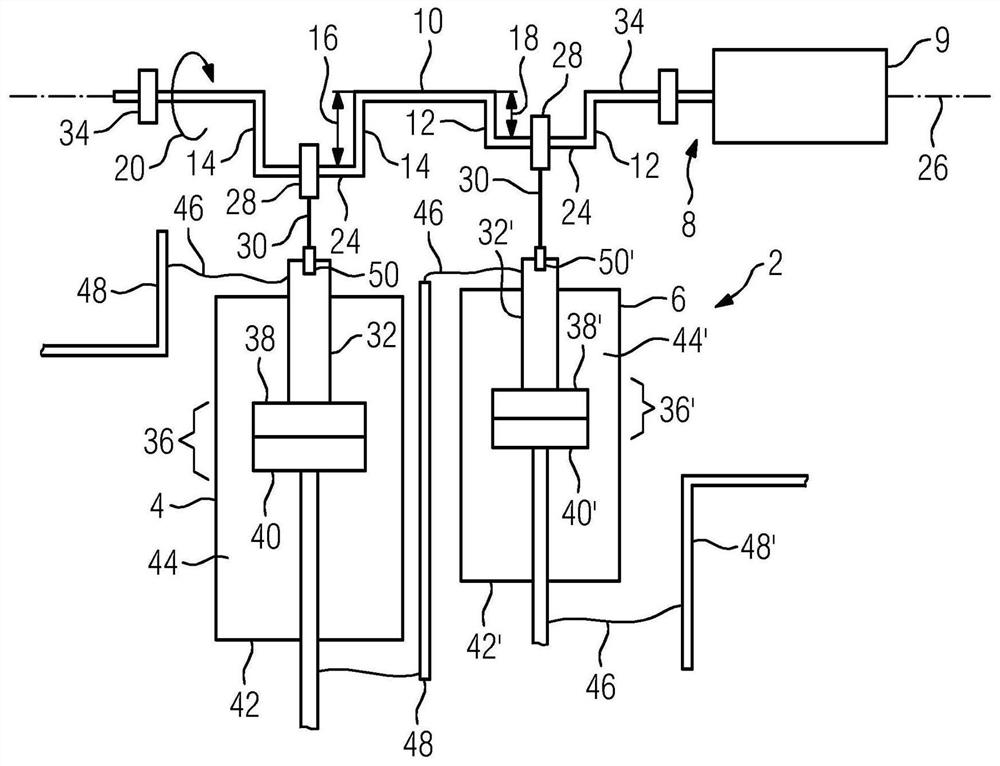

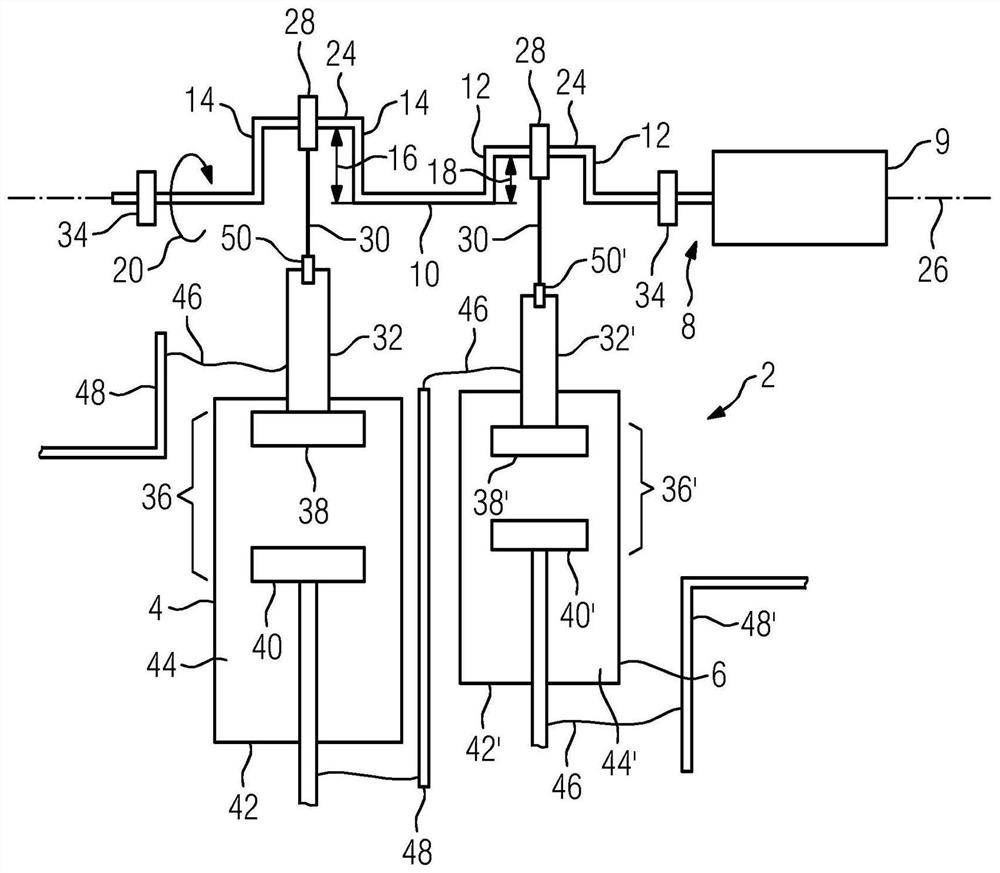

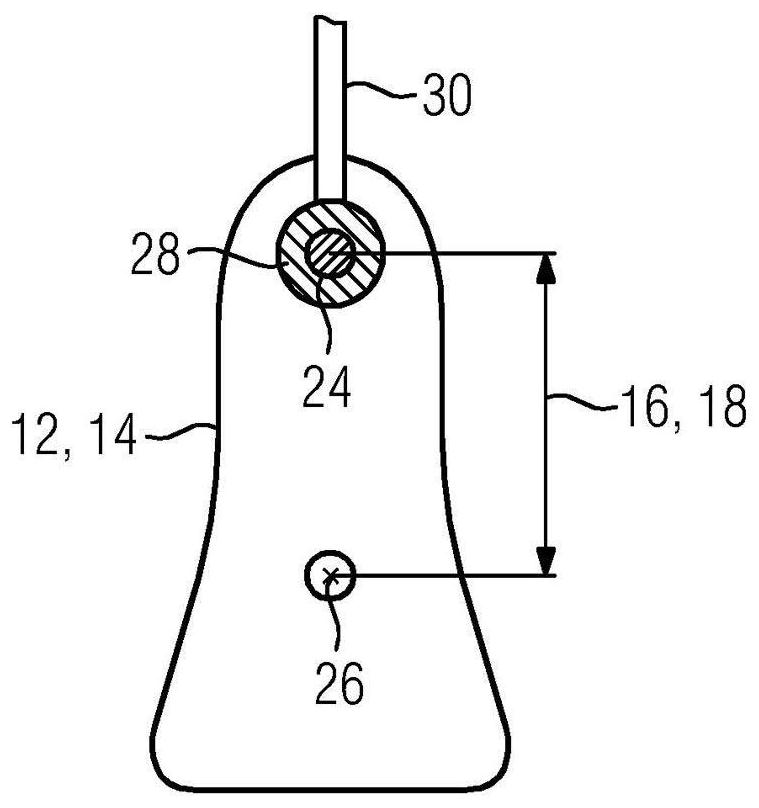

[0024] figure 1 A circuit breaker system 2 is shown in , which on the one hand has a drive system 8 which jointly drives two different circuit breaker units 4 and 6 . The drive system 8 here includes a drive unit 9 and a crankshaft 10 . In this refinement, crankshaft 10 is mounted, for example, on two crankshaft bearings 34 and performs a unidirectional rotational movement along arrow 20 . In this case, the crankshaft 10 has two cranks 12 and 14 which each have different crank strokes 18 and 16 . The term "crank 12" is also understood here to mean a pair of cranks 12 and 12' or 14 and 14' between which a crank pin 24 is arranged. The crankpin 24 extends here parallel to the axis of rotation 26 of the crankshaft 10 . During the rotational movement 20 , the crank pin 24 here describes a circular movement about an axis of rotation 26 . Slide bearings 28 are in turn connected to the crank pin 24 , these slide bearings being in connection with pushrods 30 . A further slide bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com