Self-conduction-plugging device and high-purity metal casting system

A technology of a plugging device and a casting system, which is applied to the control of pouring molten metal from a casting ladle, metal processing equipment, casting equipment, etc., can solve the problems of short service life, easy leakage, failure, etc., and achieve the effect of convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

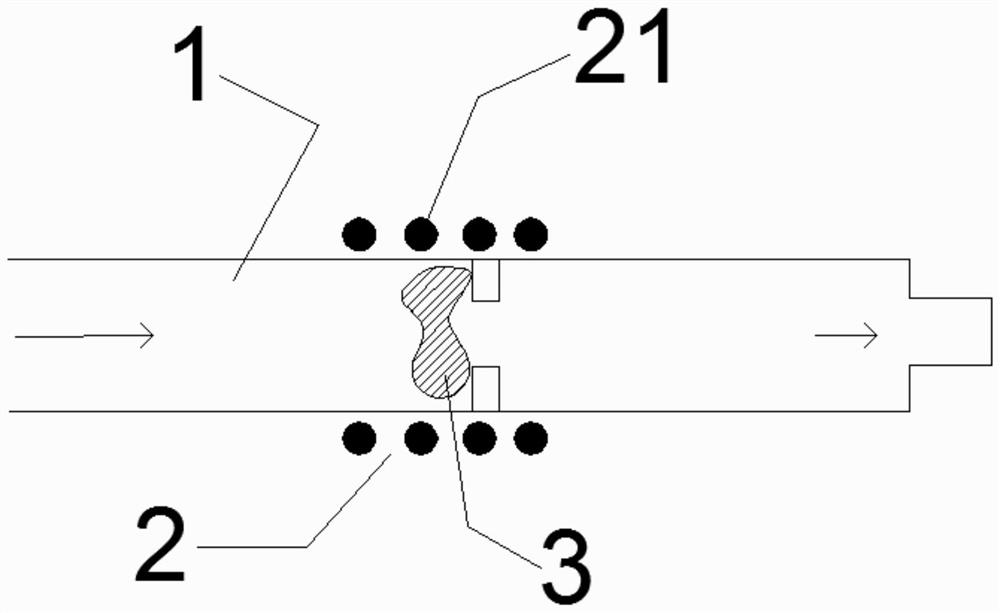

[0034] refer to figure 1 , this embodiment provides a self-conducting-blocking device, including a pipe body 1, a temperature control device 2 and a metal plug 3; wherein: the temperature control device 2 is connected to the pipe body 1, and the The metal blocking object 3 is located inside the pipe body 1; the temperature control device 2 can control the temperature of the metal blocking object 3 to form a gas-liquid state or a solid state, so as to conduct or block the pipe body.

[0035] As an optional embodiment, the temperature control device 2 includes a temperature control coil 21 , and the temperature control coil 21 is sheathed on the pipe body 1 . Since the temperature control coil 21 is used to control the temperature of the metal blockage 3 , it is most direct to put it directly on the outside of the pipe body 1 .

Embodiment 2

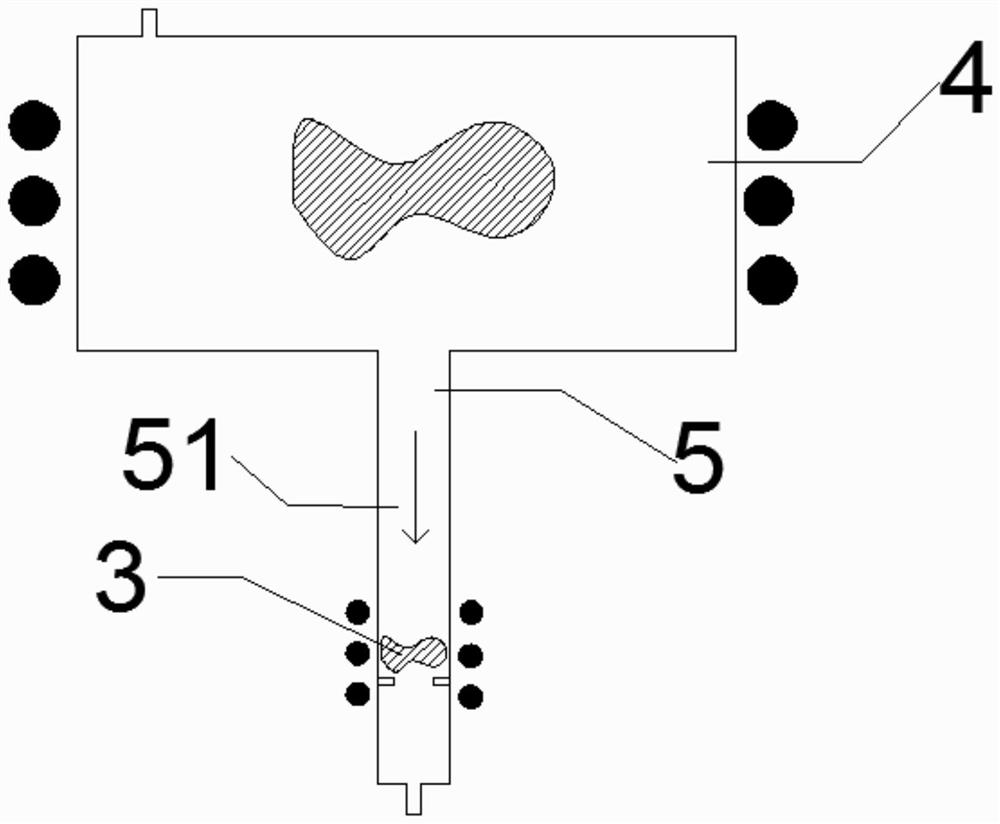

[0037] refer to figure 2 , the present embodiment provides a high-purity metal casting system, including a feeding device 4, a pipeline 5, and the self-conducting-blocking device; the feeding device 4 is used to heat the metal to provide a metal source, The metal blocker 3 and the metal source are the same metal; the pipeline 5 is arranged in communication with the feeding device 4; the self-conducting-blocking device is arranged in the middle section of the pipeline 5 .

[0038] As an optional embodiment, the feeding device 4 is a metal melting furnace. As the most commonly used heating device, metal melting furnace can heat metal to melt to provide metal liquid flow; if the heating temperature is further increased, it can also heat metal to gaseous state to provide metal vapor flow.

[0039] As an optional implementation, the metal melting furnace is externally connected with a vacuum pump. As mentioned above, since the metal blockage in the self-conduction-blocking devi...

Embodiment 3

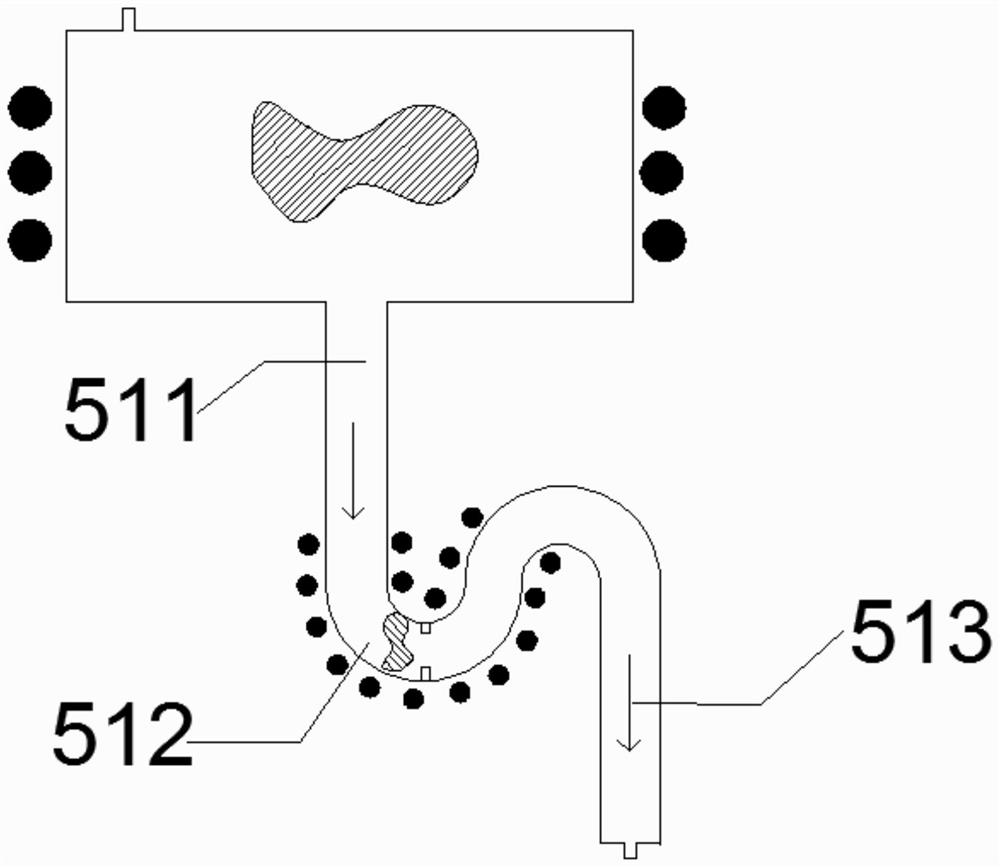

[0042] refer to image 3 This embodiment also provides a high-purity metal casting system. The difference from Embodiment 3 is that in this embodiment, the first pipeline 51 includes an inlet portion 511, a bending portion 512, and an outlet portion 513; The inlet portion 511 is vertically arranged parallel to the outlet portion 513 ; the bent portion 512 is arranged between the inlet portion 511 and the outlet portion 513 .

[0043] Such an arrangement can keep the bent portion 512 in a state of metal flow all the time, and it is beneficial to reduce the temperature for sealing when the casting is finished.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com