Wafer manufacturing tool and use method thereof

A wafer and tool technology, applied in the field of wafer manufacturing tools, can solve the problem of reducing finishing processing, and achieve the effects of reducing finishing processing, increasing quality, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

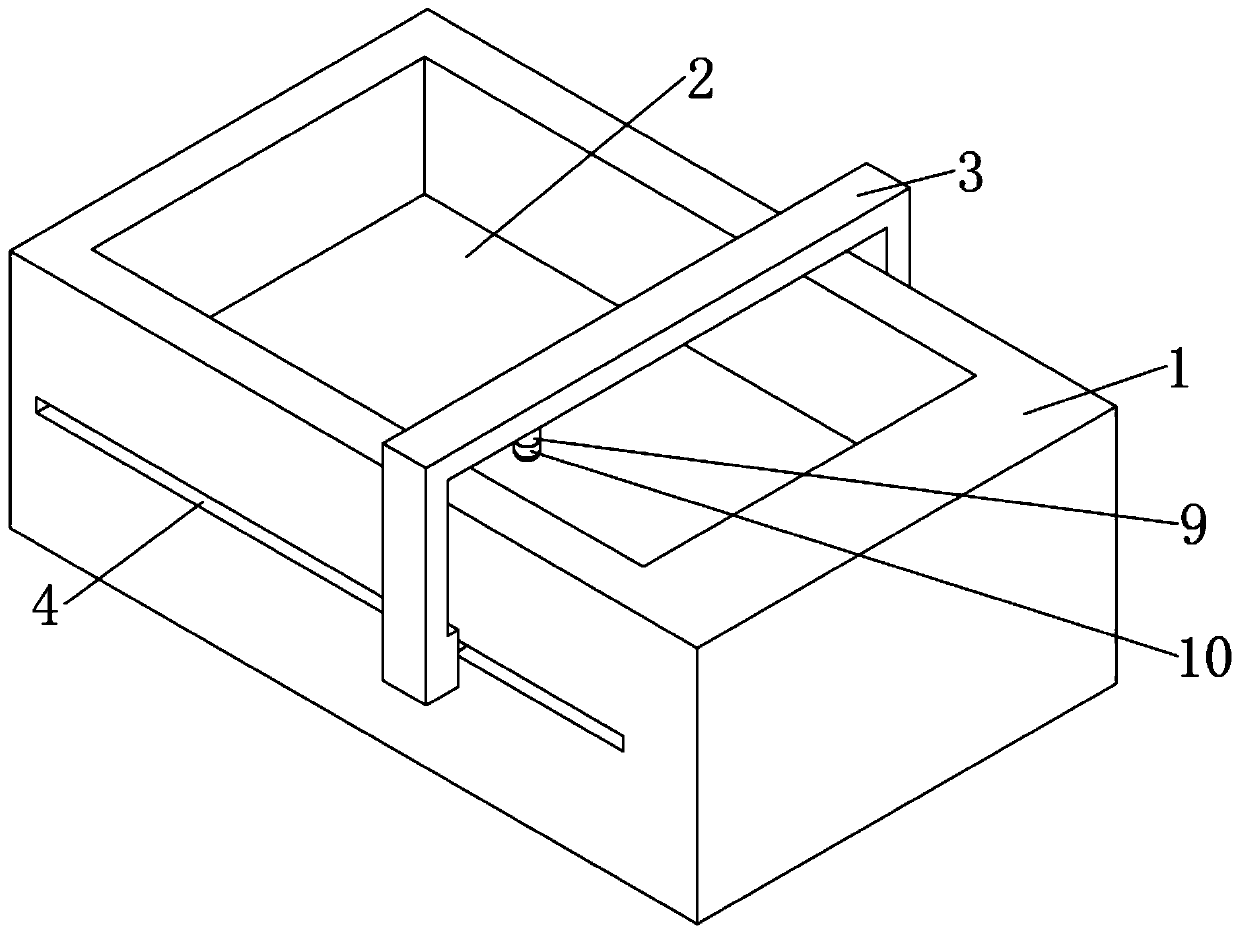

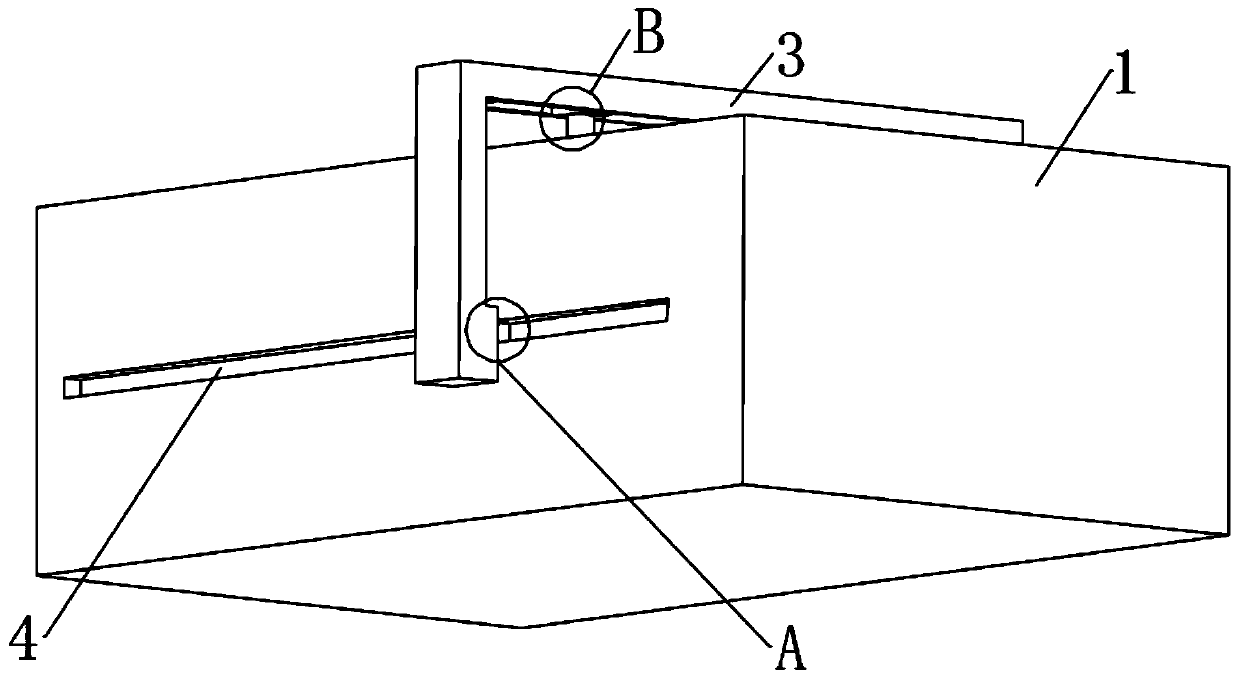

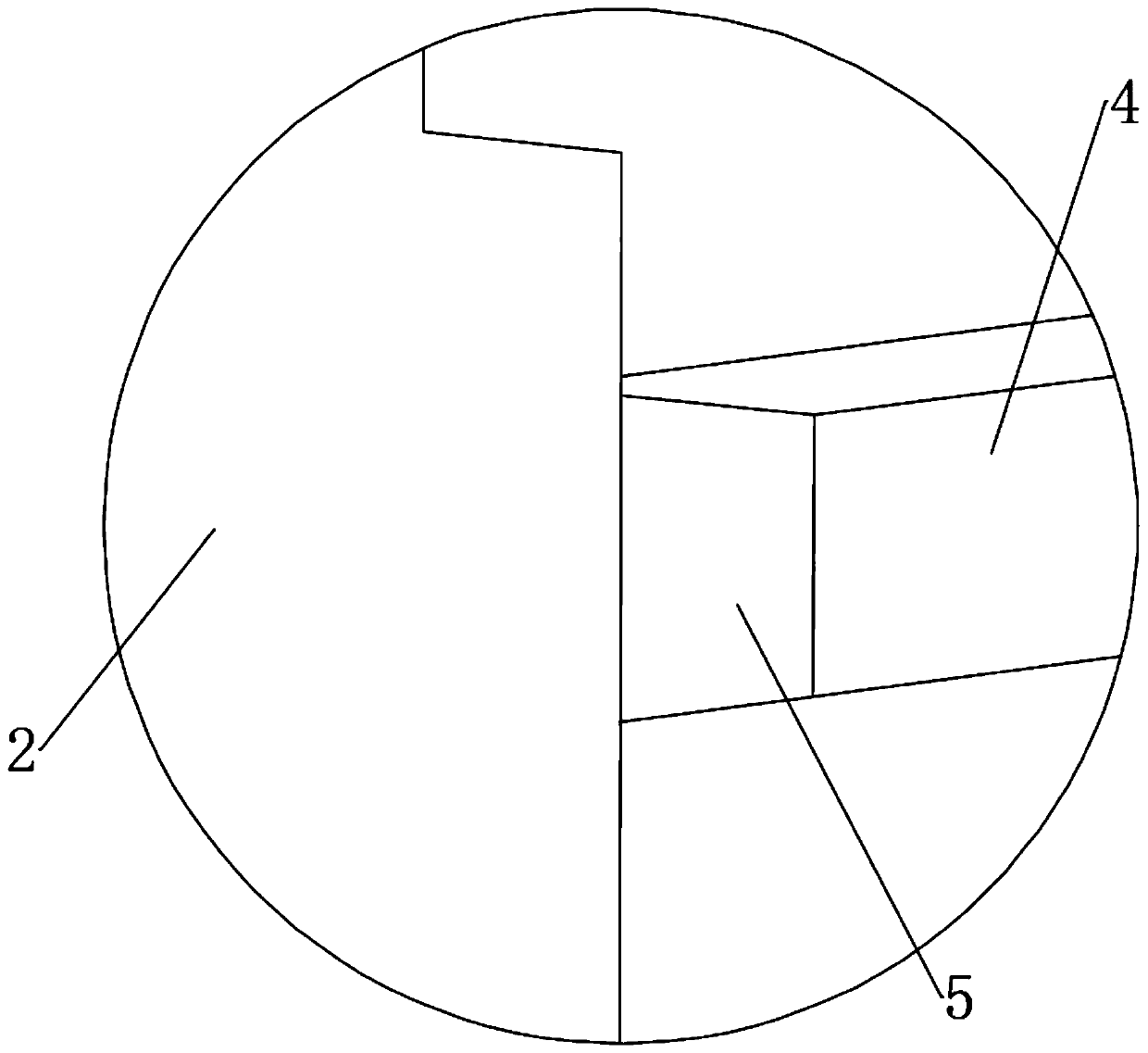

[0043] see Figure 1-6 , a wafer manufacturing tool, comprising a base 1, the upper end of the base 1 is dug with a water tank 2, the upper side of the base 1 is provided with a main body 3 of a mechanical arm, and the main body 3 of the mechanical arm is in the shape of a "door". A pair of first electromagnetic slide rails 4 are excavated on the side wall of the platform 1, and a section of the lower ends of the two mechanical arm bodies 3 close to the base 1 is fixedly connected with a first electromagnetic slide block 5 matching the first electromagnetic slide rails 4, The base 1 and the main body of the mechanical arm 3 are slidably connected through the first electromagnetic slide rail 4 and the first electromagnetic slider 5. A second electromagnetic slide rail 7 is excavated on the side close to the base 1 at the upper end of the main body 3 of the mechanical arm. The second electromagnetic slide rail 7 is slidingly connected with a second electromagnetic slider 8, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com