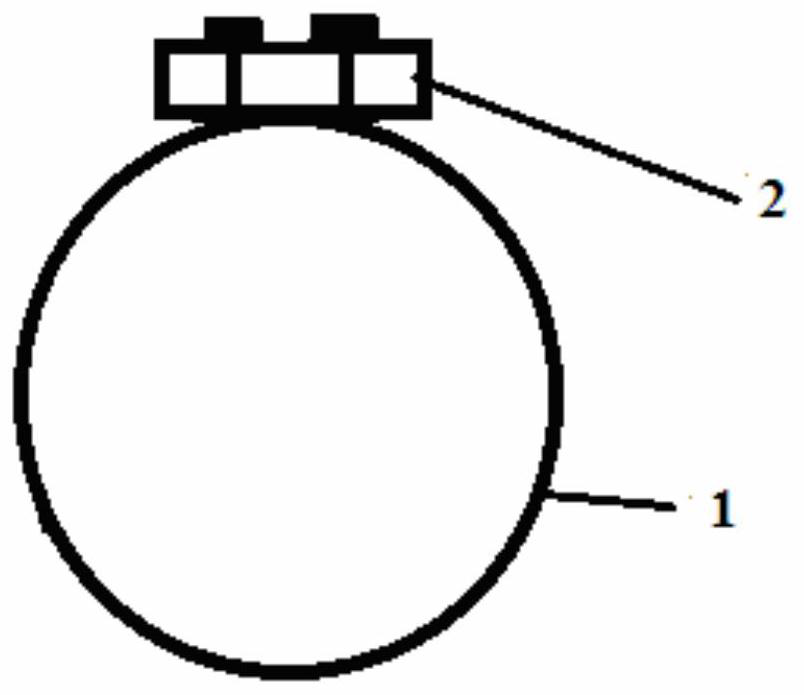

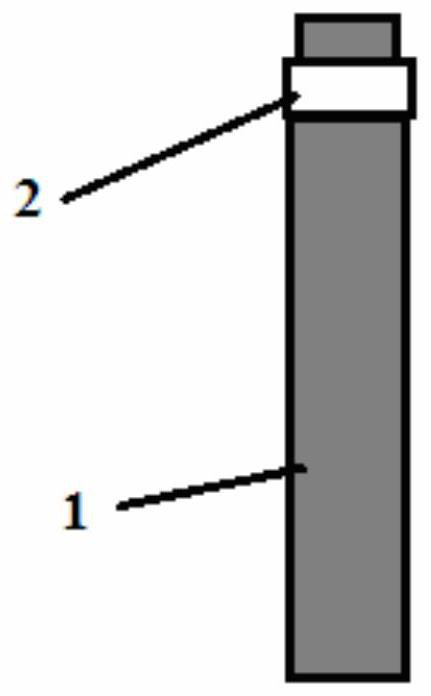

A throat hoop type shape memory alloy fastener

A memory alloy and fastener technology, which is applied in the field of shape memory alloy fasteners and throat hoop type shape memory alloy fasteners, can solve problems such as lack, and achieve high fastening force value, high restoring force value, The effect of excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] According to the required fastening object - soft and hard pipe, the actual use effect observation is carried out. The selected plastic hard pipe is a fastening object of standard size, its outer diameter is 20mm, and the wall thickness of the plastic hose is 0.8mm. After the hard tube is installed on the hose jacket, the wall thickness of the hose is slightly reduced. The outer diameter of the joint of the soft and hard tube is about 21.2mm, and its circumference is about 66.5mm.

[0072] Choose matching fasteners with shape memory hoops. The material of the hoops is titanium-nickel alloy, which is 44% titanium and 56% nickel by mass percentage, and the reverse phase transition temperature is 40°C. The hoop was subjected to stress aging treatment, aged at 350°C for 4 hours at a medium temperature, and a stress of 400 MPa was applied in a direction parallel to the ring shape of the hoop at the same time. The thickness of the hoop is 0.5mm, the width is 3mm, and the ini...

Embodiment 2

[0075] According to the required fastening object - soft and hard pipe, the actual use effect observation is carried out. The selected plastic hard pipe is the fastening object of standard size, and the fastener with the shape memory effect hoop matching the fastening object-soft and hard pipe is selected. The hoop material is titanium-nickel alloy, which is calculated by mass percentage , 44% titanium, 56% nickel, and its inverse phase transition temperature is 40°C. The hoop was subjected to stress aging treatment, aged at 300°C for 5 hours at a medium temperature, and a stress of 500 MPa was applied in the direction parallel to the ring shape of the hoop at the same time. Both ends of the hoop are fixed by welding. First, the hoop is pre-stretched with a stretch ratio of 5%. After unloading, it is slightly larger than the outer diameter circumference of the joint of the soft and hard pipe. Then, put the ferrule on the connection between the soft and hard pipes. Finally, ...

Embodiment 3

[0078] According to the required fastening object - soft and hard pipe, the actual use effect observation is carried out. The selected plastic hard pipe is the fastening object of non-standard size, and the fastener with the shape memory effect hoop matching the fastening object-soft and hard pipe is selected. The hoop material is made of shape memory alloy and high elastic plastic The composite material is formed by wrapping the shape memory alloy with highly elastic plastic, and the shape memory alloy is an iron-nickel-cobalt-titanium alloy, and its mass percentage is 55% iron; 31% nickel; 10% cobalt; and 4% titanium. The hoop is subjected to stress aging treatment, aged at 400°C for 3 hours at a medium temperature, and a stress of 300 MPa is applied in a direction parallel to the ring shape of the hoop at the same time. The hoop is secured with a snap-on fastening. First, the hoop is pre-stretched with a stretch ratio of 9%. After unloading, it is slightly larger than the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com