Osmotic pressure-driven two-phase fluid loop

A fluid circuit, osmotic pressure technology, applied in lighting and heating equipment, indirect heat exchangers, etc., can solve problems such as insufficient capillary driving force, insufficient capillary driving force, and insufficient liquid stability, and achieve flow distribution. Uneven and mutual interference problems, improve transmission distance and heat transfer capacity, and achieve simple and easy results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0030] The present invention provides a two-phase fluid circuit driven by osmotic pressure.

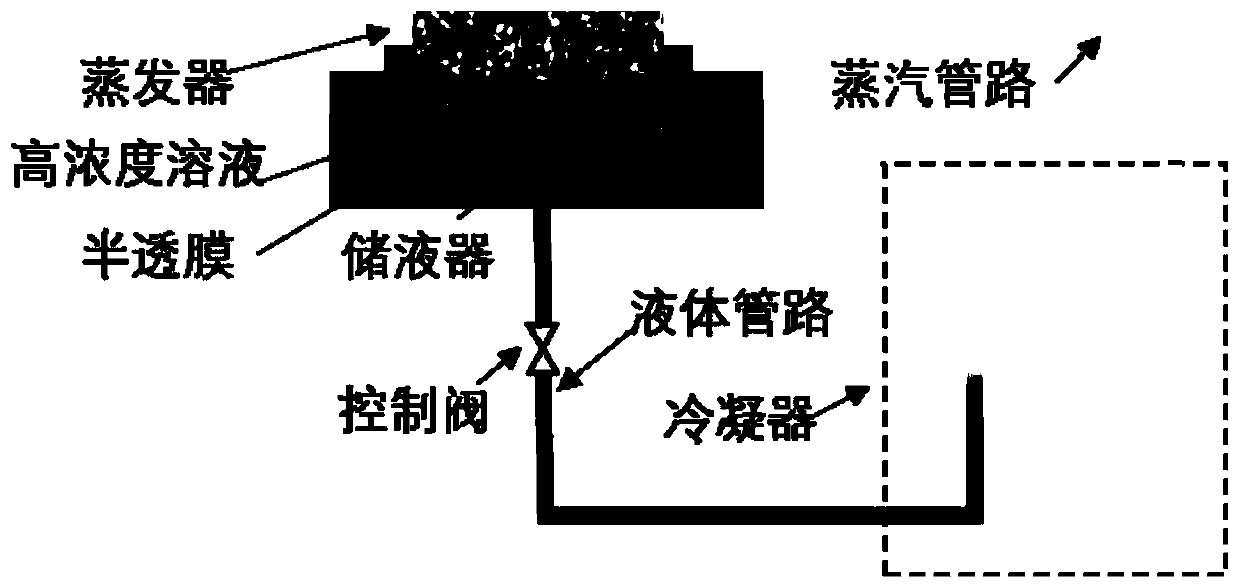

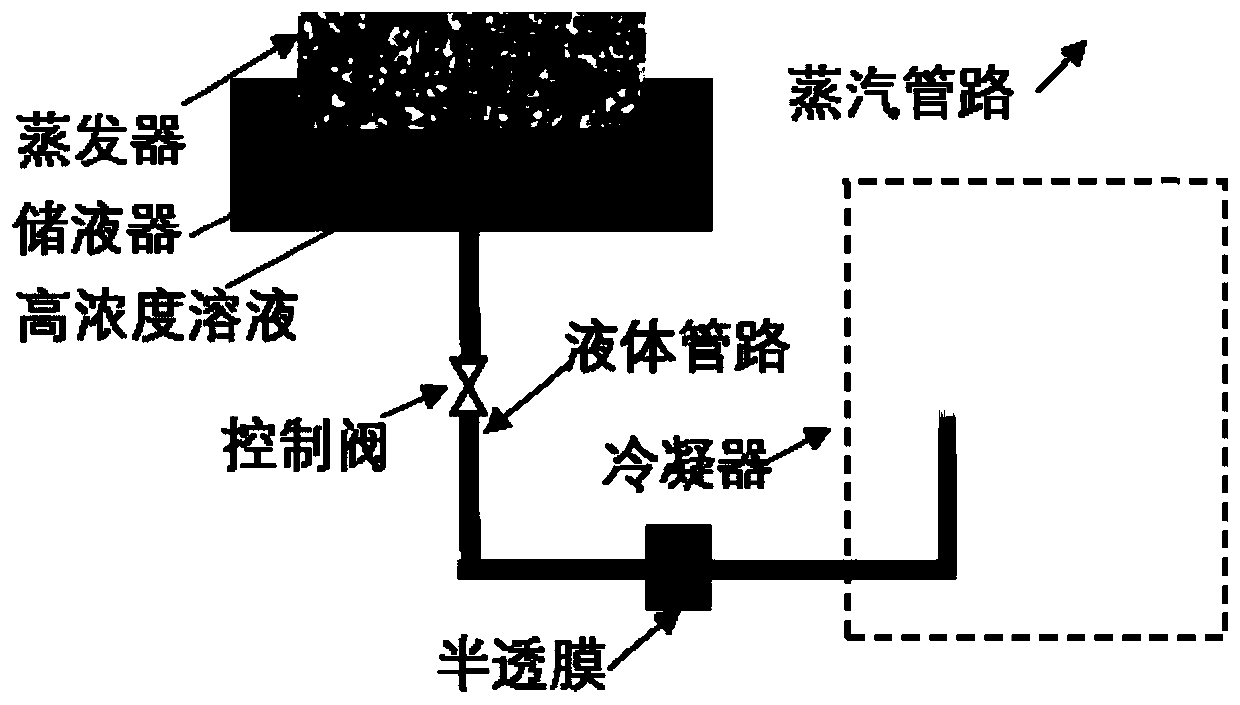

[0031] The two-phase fluid circuit includes a liquid receiver, an evaporator, a steam pipeline, a condenser and a liquid pipeline. The working medium in the liquid receiver enters the evaporator under the action of a driving force and becomes gaseous, and the gaseous working medium arrives through the steam pipeline. Condenser, the heat of the working medium is transferred to the equipment through the condenser, the gaseous working medium in the circuit becomes liquid, and the liquid working medium returns to the liquid receiver through the liquid pipeline; the working medium circulates continuously under the action of the driving force to realize heat transfer . The loop is similar to a loop heat pipe, forming a vacuum loop in which the vapor / liquid working medi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com