ISO Tank bottom valve connector thread cleaning device

A cleaning device and interface technology, applied in the direction of thread cutting device, maintenance and safety accessories, thread cutting machine, etc., can solve the problems of troublesome disassembly operation, high cost, serious residual material, etc., and achieve the effect of cost saving, convenient portability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

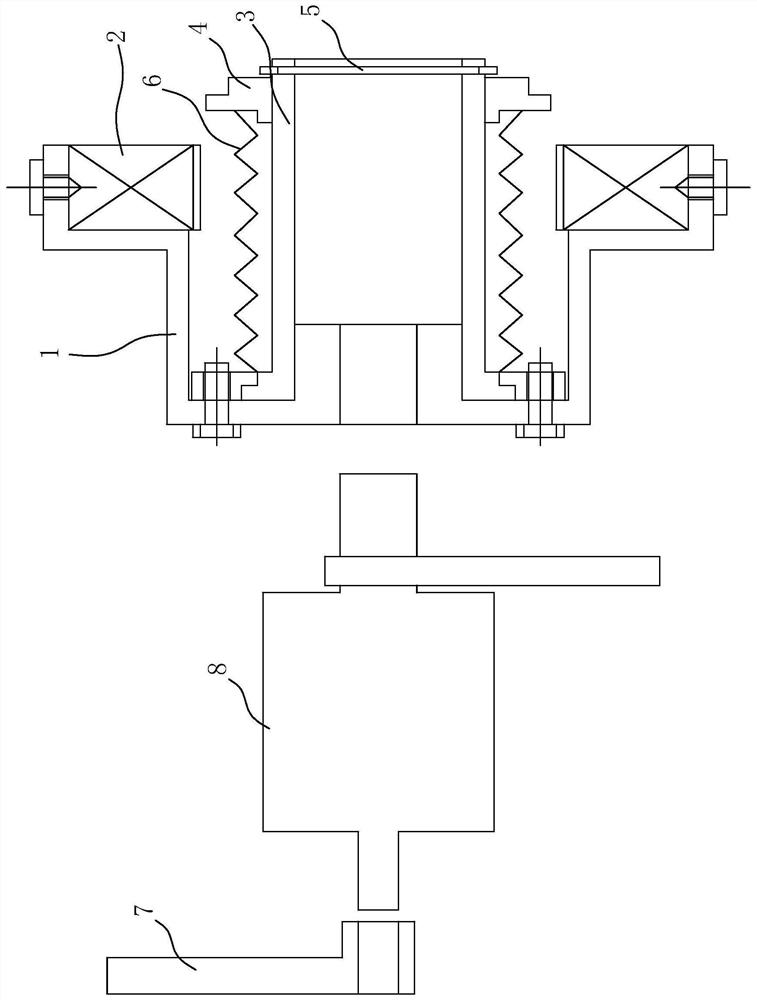

[0011] Such as figure 1 As shown, an ISO Tank bottom valve interface thread cleaning device includes a sleeve 1 that can be rotated by torsion. The inner peripheral wall of the sleeve 1 is fixed with a circular die 2 that is threaded with the ISO Tank bottom valve interface. A center shaft 3 extending toward the inner hole of the ISO Tank bottom valve interface is fixed, and a positioning sliding sleeve 4 is installed axially on the center shaft 3 to coincide with the inner hole of the ISO Tank bottom valve interface. The outer end of the center shaft 2 is installed to block the positioning A compression spring 6 is installed between the retaining ring 5 of the sliding sleeve 4 and the inner end of the sleeve 1 and the positioning sliding sleeve 4 .

[0012] When the external thread of the ISO Tank bottom valve interface needs to be cleaned, the central axis 3 of the device should face the inner hole of the ISO Tank bottom valve interface, and then turn the sleeve 1 to screw t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com