Welding system for two-core wire and DC terminal

A welding system and core wire technology, used in welding equipment, welding/welding/cutting items, connections, etc., can solve problems such as poor position accuracy, inability to weld short wire ends, and inability to weld long wire ends.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

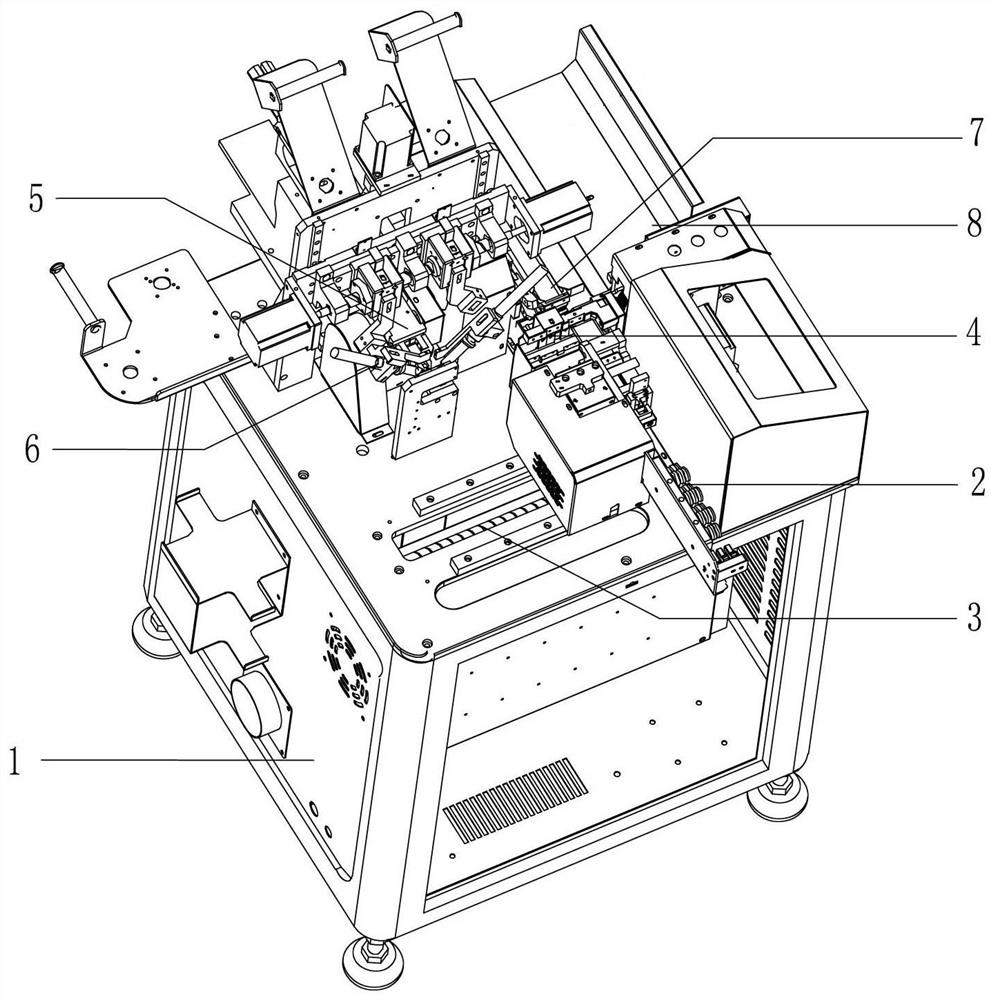

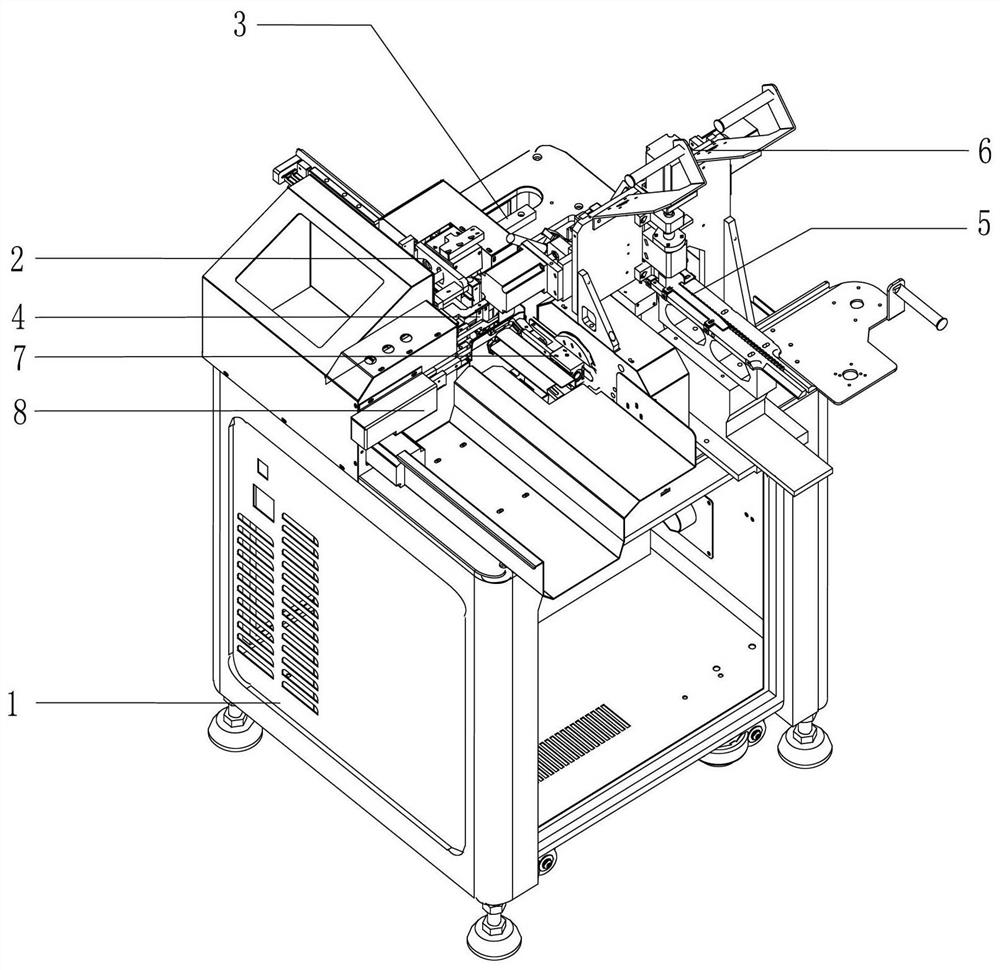

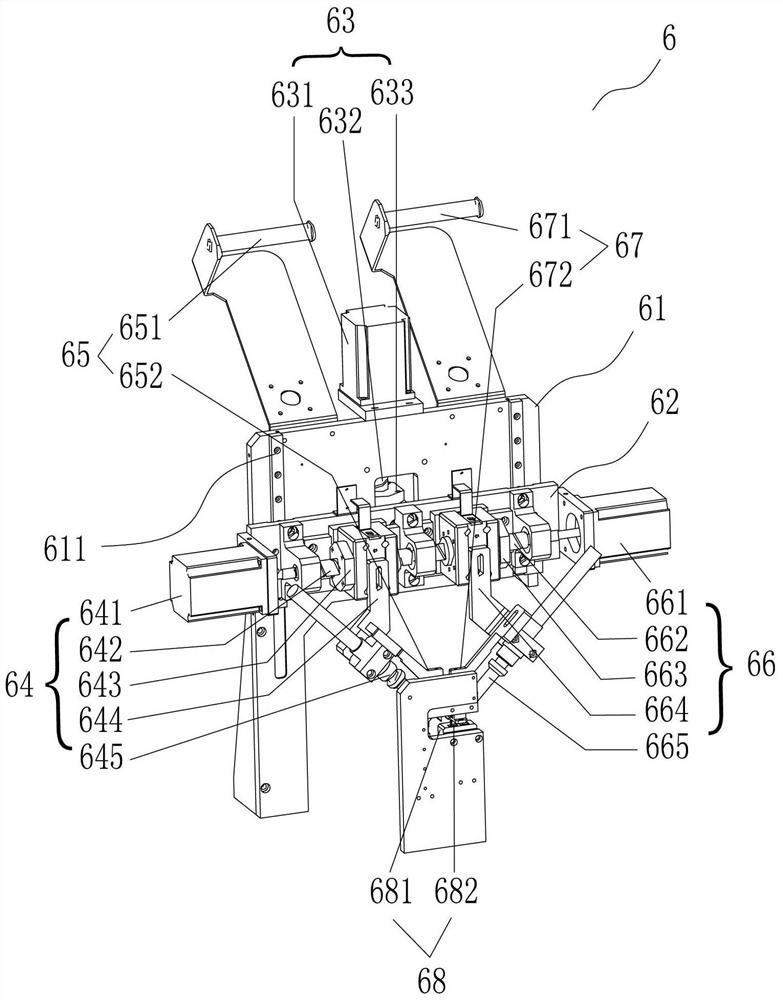

[0022] Such as Figure 1-Figure 2 As shown, it is a fully automatic two-core wire and DC terminal welding and tin bonding machine applying the present invention. The fully automatic two-core wire and DC terminal welding and tin bonding machine includes machine 1 and is installed on machine 1. The above two-core wire feeding device 2, two-core wire translation transmission device 3, two-core wire cutting device 4, DC terminal conveying device 5, welding system 6, tin sticking device 7 and discharge device 8, among which:

[0023] The two-core wire feeding device 2 is used to convey the two-core wire and clamp the two-core wire, and is installed on the two-core wire translation transmission device 3;

[0024] The two-core wire translation transmission device 3 is used to transfer the two-core wire feeding devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com