Hook and label plate penetrating-connecting system

A label and threading technology, applied in the field of hook and label threading system, can solve problems such as difficulty in identifying and hanging, burns, lack of labels, etc., to ensure personnel safety, improve efficiency and success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

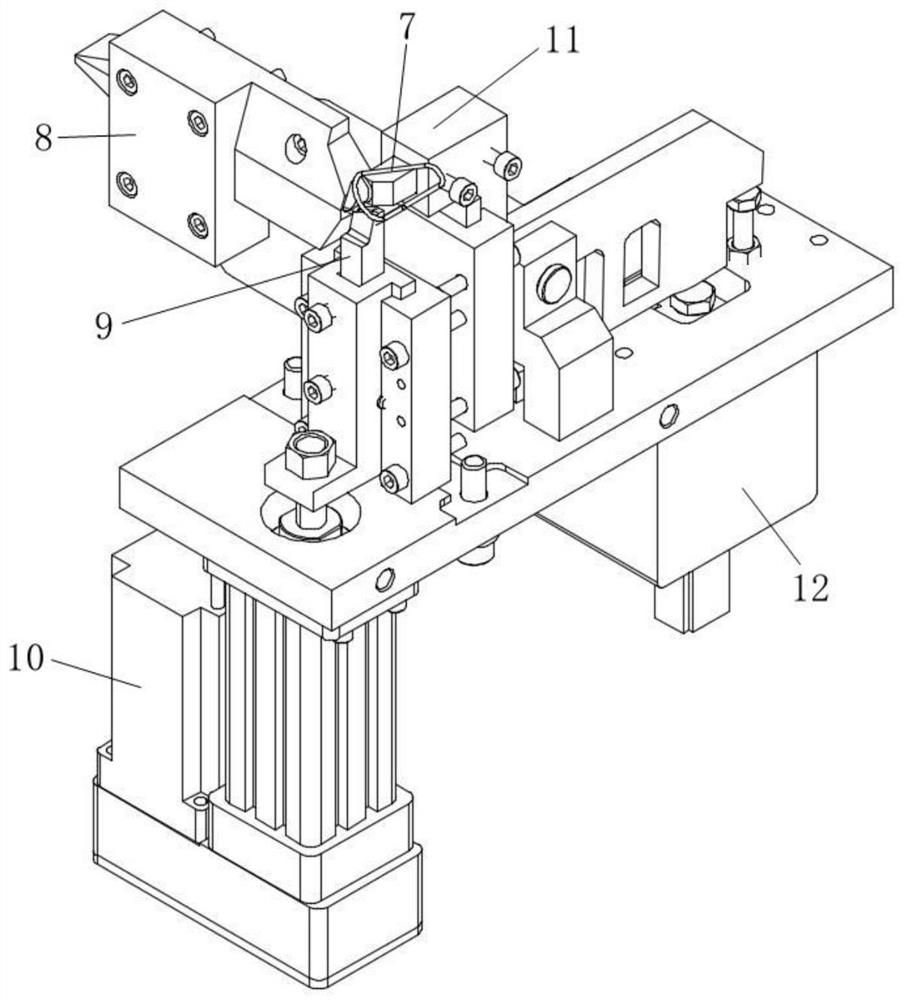

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] It is worth noting that the orientation words such as "up" and "down" involved in this article are all determined relative to the perspective of the drawings, and are only for the convenience of description, and cannot be understood as limitations on the technical solution.

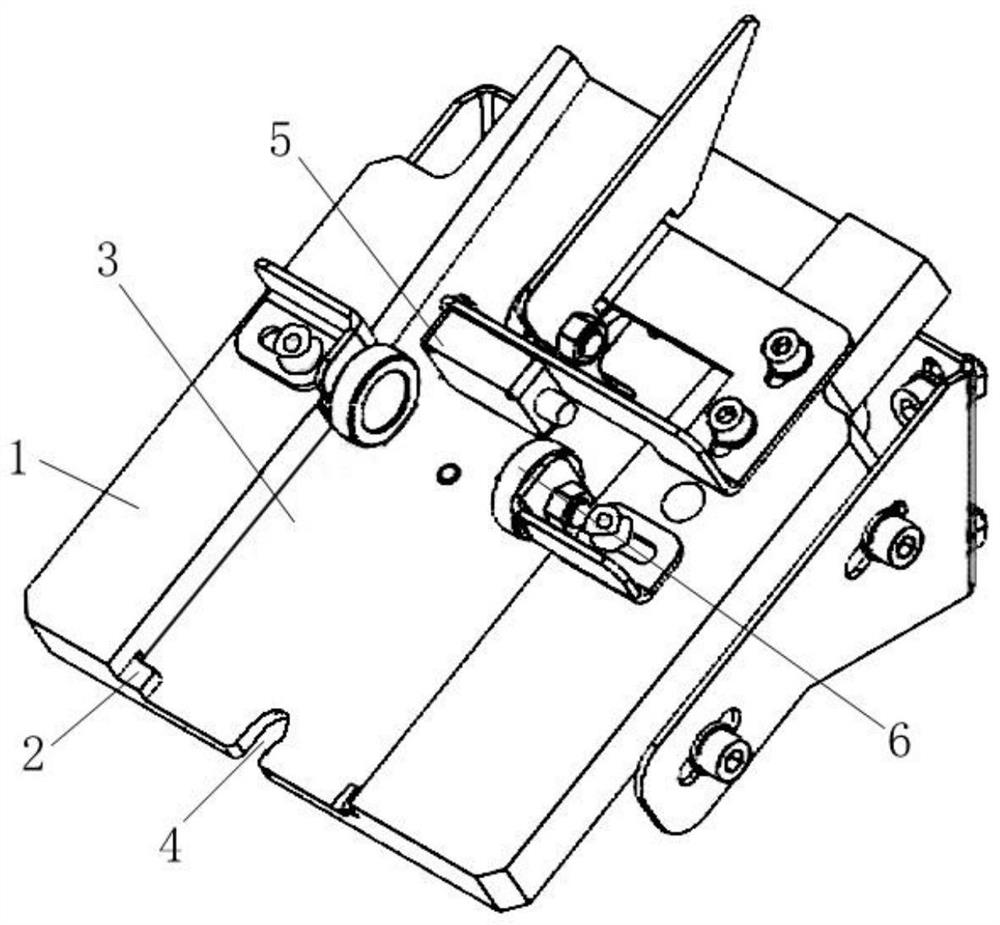

[0029] Wire rod is the one with the smallest cross-sectional size of hot-rolled section steel. Generally, wire rods are stored in bundles. Labels need to be hung on the wires. Since the steel wires need to be wound multiple times when using steel wires to bind the wires, the camera needs to identify the place where they can be hung.

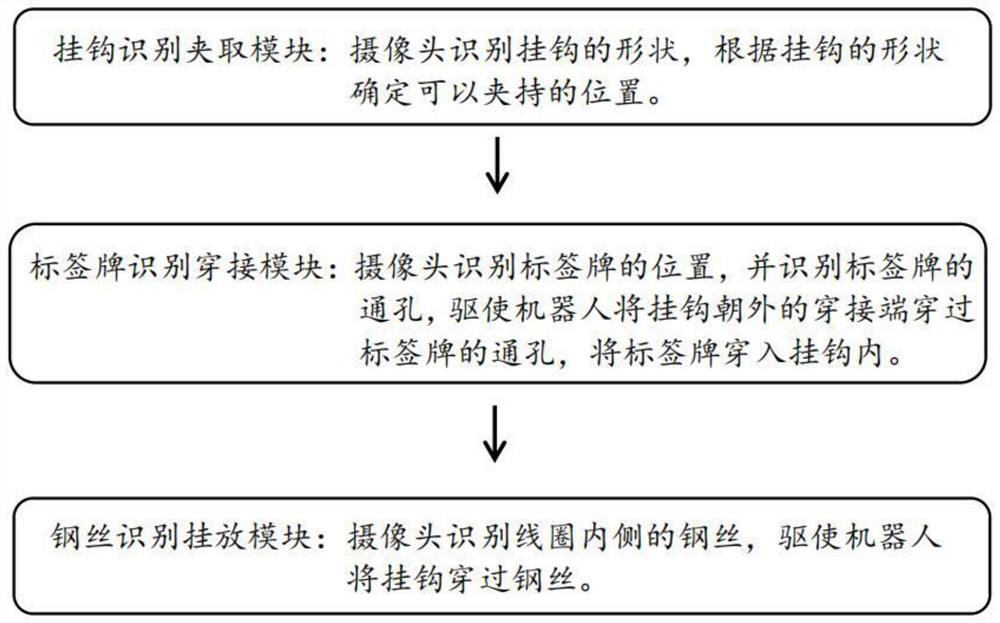

[0030] like Figure 1-4 As shown, the present invention provides a hook and tag threading system to solve the existing problems, which is applied to a robot with a camera, including a motion module, a hook identification and clamping module,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com