A plastic molding device with self-lubricating and noise reduction functions

A plastic molding and self-lubricating technology, applied in the field of plastic molding devices, can solve the problems of waste, difficulty in controlling the amount of lubricating oil added, loud noise, etc., and achieve the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

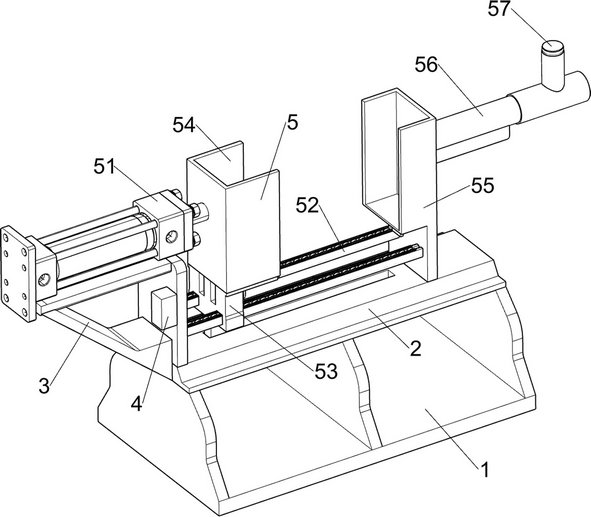

[0029] A plastic molding device with self-lubricating and noise-reducing functions, such as Figure 1-8 As shown, it includes a base 1, a slotted base plate 2, a triangular support frame 3, a control center module 4, an injection molding assembly 5, a translation noise reduction assembly 6 and a self-lubricating assembly 7. The top of the base 1 is fixedly installed with a slotted base plate 2, A triangular support frame 3 is fixedly connected to the left side of the slotted bottom plate 2, and a control center module 4 is fixedly installed on the triangular support frame 3. The control center module 4 is used to control the operation of the equipment. The noise reduction component 6 is arranged on the injection molding component 5 , and the translation noise reduction component 6 is used to reduce the noise during the movement of the injection molding component 5 . The self-lubricating component 7 for adding lubricating oil is also arranged on the injection molding component 5...

Embodiment 2

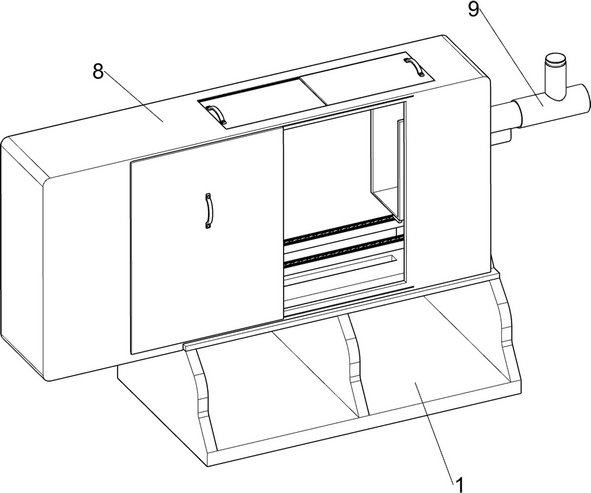

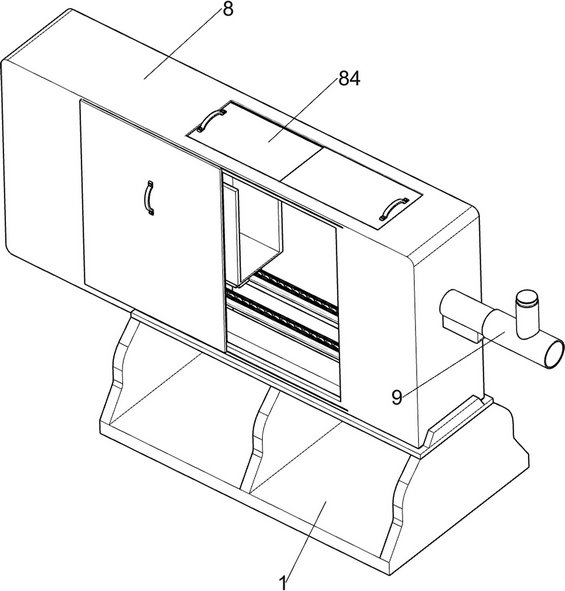

[0038] On the basis of Example 1, as Figure 8 As shown, a closed noise reduction assembly 8 is also included, and a closed noise reduction assembly 8 is fixedly installed on the slotted bottom plate 2. The closed noise reduction assembly 8 is used to isolate the sound generated when the component is running. The closed noise reduction assembly 8 includes a closing plate 81, an opening and closing door frame 82, a handle 83, a top sliding plate 84 and a top sliding plate 2 85, a closing plate 81 is fixedly installed on the slotted bottom plate 2, and the closing plate 81 is used to isolate the internal components. , the injection pipe 56 passes through the closing plate 81, the front side of the closing plate 81 is slidably connected with the opening and closing door frame 82, the opening and closing door frame 82 is convenient for the staff to place the mold, and the front side of the opening and closing door frame 82 is fixed with a handle 83 that is easy to hold, A top slid...

Embodiment 3

[0041] On the basis of Example 2, as figure 1 , Figure 8 As shown, noise-absorbing cotton 9 is also included, and the injection-molding tube 56 is covered with noise-absorbing cotton 9 , which is used to eliminate the sound of the raw material colliding with the injection-molding tube 56 .

[0042] When the raw material flows through the injection pipe 56 to the fixed mold placement seat 55, the raw material will make a sound, and the muffler cotton 9 can eliminate the sound of the collision between the raw material and the injection pipe 56, so that the staff will not generate large noise when using this equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com