Laminated surface paper with avoiding belts and manufacturing method of uncovered line-drawing-free open box

A face paper and gluing technology, which is applied in box making operations, rigid/semi-rigid container manufacturing, papermaking, etc., can solve problems such as wire drawing, occurrence of wire drawing, and non-compliance with factory specifications, so as to reduce the rate of defective products and reduce the cost of promotion low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

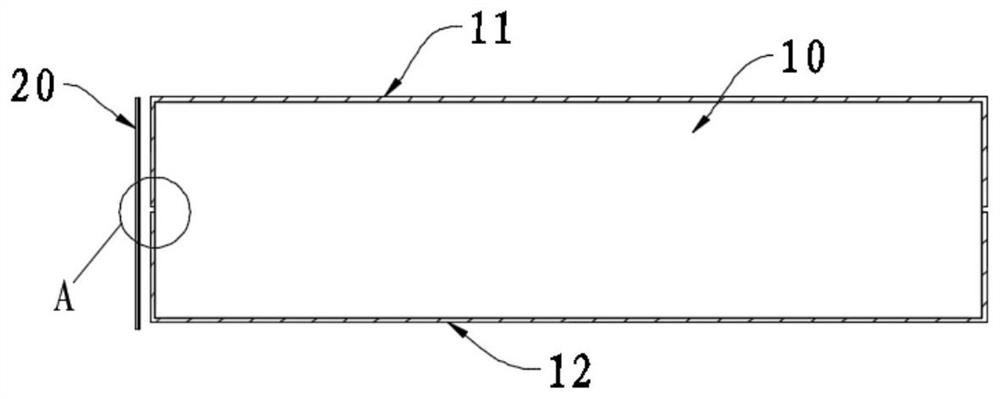

[0039] Such as figure 1 As shown, the inner box 10 includes a sky cover 11, a ground cover 12, and an inner mold. The inner mold is packaged between the sky and the ground cover. The gap between the sky and the ground cover corresponds to the opening path in the downstream process of the open box. The outer paper 20 is glued through the traditional gluing process to obtain a gluing surface paper with the effect of gluing the entire surface. The outer box is obtained by pasting and covering the outer surface of the inner box with tissue paper.

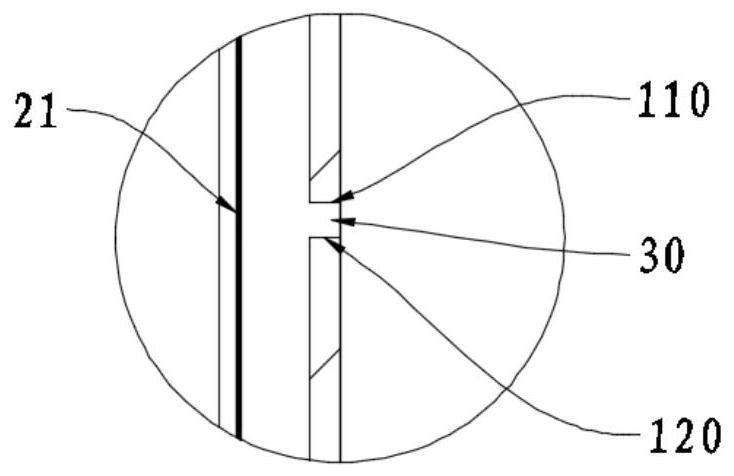

[0040] Such as figure 2 As shown, in the downstream process, the outer box will be pressed through the glued surface of the outer box to squeeze out the air bubbles and flatten the paper surface. But in the extrusion process, the glue 21 will spread. After the glue 21 diffuses into the gap 30, there will be adhesion between the end face 110 of the sky cover and the end face 120 of the ground cover, and the upper cover and the lower ...

Embodiment 2

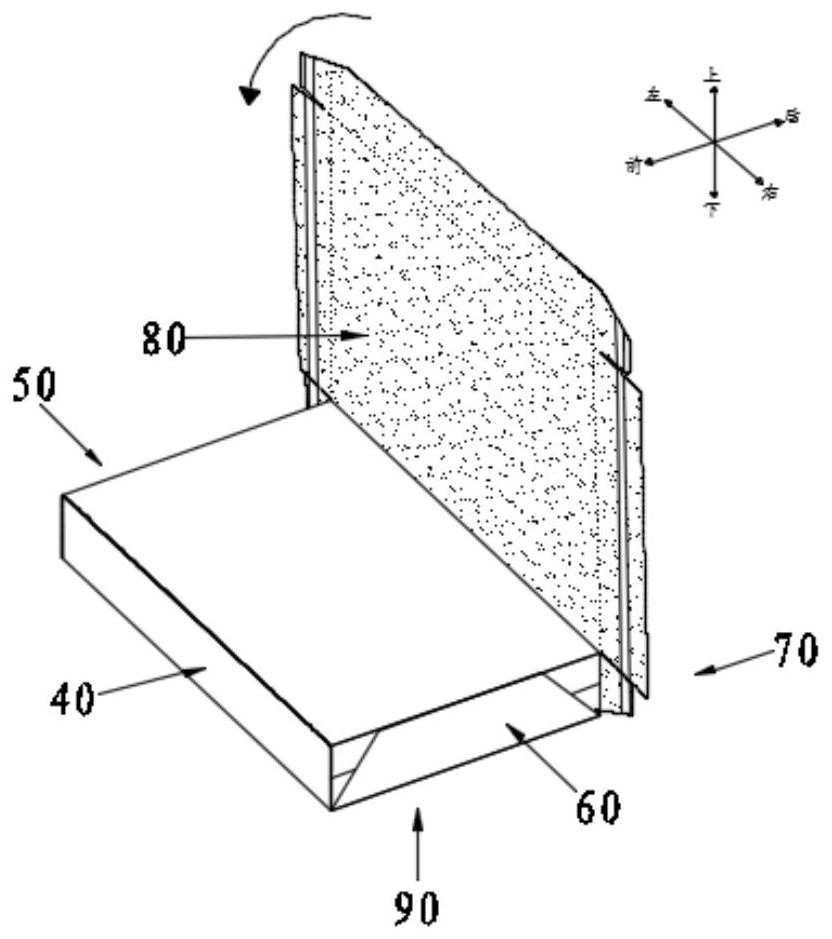

[0064] This embodiment provides a glued surface paper with an escape belt, which can completely avoid the stringing phenomenon of the open box and avoid the waste of glue.

[0065] Compared with the glued face paper in the first embodiment, the glued face paper in the present embodiment is provided with glue escape belts on the front inner layer 41 and the front outer layer 42 .

[0066] Referring to the face paper in the flattened state, the two glue avoidance strips on the left and right sides are arranged along the extending direction of the two sides, and the two avoiding strips on the front side extend along the length direction of the edge of the front side Arrangement, two kinds of avoidance belts intersect on the left ear two 54 and the right ear two 64 respectively.

[0067] After wrapping the inner box with this kind of glued surface paper to form the outer box, the avoidance belts on the front, rear, left, and right sides of the outer box all correspond to the gaps ...

Embodiment 3

[0071] This embodiment provides a glued surface paper with an escape belt, which can completely avoid the stringing phenomenon of the open box.

[0072] Compared with the glued face paper in the first embodiment, the glued face paper in the present embodiment has the front inner layer 41, the left inner layer 51, the left ear one 52, the left ear two 54, the right inner layer 61, and the right ear One 62 and right ear two 64 are provided with avoidance belts, and these surfaces are completely attached to the inner box after molding and are located in the inner layer. After wrapping the inner box with this kind of glued surface paper to form the outer box, the avoidance belts on the inner layer on the front, rear, left, and right sides of the outer box correspond to the gaps in the inner box, and the knife is cut along the cutting path to completely avoid glue and perfectly eliminate The appearance of drawing phenomenon.

[0073] This embodiment can be obtained by prefabricati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com