Anti-overload potting process for missile-borne product

An anti-overload, product technology, applied in the direction of ammunition, weapon accessories, offensive equipment, etc., can solve the problems of poor potting uniformity, affecting potting effect, and complicated potting operations, so as to prevent leakage of potting glue and maintain potting. Uniformity, the effect of improving potting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

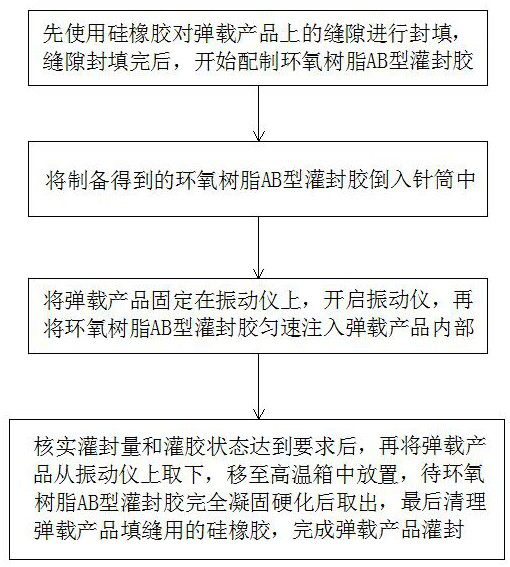

[0038] see figure 1 , a ballistic product anti-overload potting process, comprising the following steps:

[0039] a. First use silicone rubber to seal the gaps on the bomb-loaded products. After the gaps are filled, start to prepare epoxy resin AB-type potting glue. The preparation ratio of epoxy resin AB-type potting glue is A-type glue: B-type glue is 2:1, pour B-type glue into the container and weigh, then pour A-type glue into the container according to the proportion, and stir at a uniform speed;

[0040] b. Take out the pushing and compressing part of the syringe, pour the prepared epoxy resin AB type potting compound into the syringe, and then put the pushing and compressing part into the syringe;

[0041] c. Fix the bomb-loaded product on the vibrator, make the glue filling hole of the bomb-loaded product face up, the needle of the syringe extends into the inside of the bomb-loaded product from the glue filling hole, turn on the vibrator, and then pour epoxy resin AB ...

Embodiment 2

[0045] see figure 1 , on the basis of Example 1, further, preferably:

[0046] In the step a, the silicone rubber is 704 silicone rubber, and the use of silicone rubber to seal the gaps on the missile-borne products specifically refers to using a sealing rod to evenly apply 704 silicone rubber to the gaps of the missile-borne products.

[0047] In the step a, the uniform directional stirring specifically refers to stirring clockwise at a stirring speed of 150 r / min, and the stirring time is 3 min.

[0048] In the step a, the viscosity of type A glue is 500cps, and the viscosity of type B glue is 400cps.

[0049] In the step c, the epoxy resin AB-type potting glue is injected into the missile-borne product at a uniform speed, specifically at a speed of 7ml / min.

[0050]This embodiment is a preferred implementation manner, which can effectively prevent the leakage of the potting compound, and is beneficial to improve the potting quality.

Embodiment 3

[0052] see figure 1 , on the basis of Example 1, further, preferably:

[0053] In the step a, the silicone rubber is 704 silicone rubber, and the use of silicone rubber to seal the gaps on the missile-borne products specifically refers to using a sealing rod to evenly apply 704 silicone rubber to the gaps of the missile-borne products. Uniform directional stirring specifically refers to stirring clockwise at a stirring speed of 200 r / min, and the stirring time is 4 minutes. The viscosity of type A glue is 600cps, and the viscosity of type B glue is 500cps.

[0054] In the step c, the epoxy resin AB-type potting compound is injected into the missile-borne product at a uniform speed, which specifically refers to injection at a speed of 9ml / min.

[0055] In the step d, moving to a high-temperature box means keeping the temperature of the high-temperature box at 40° C. for 6 hours.

[0056] This embodiment is yet another preferred implementation mode, which can completely solid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com