Data chain device suitable for high overload impact environment, and potting method thereof

A technology that impacts the environment and data link. It is applied to the circuit layout, sealed casing, electrical components and other directions on the support structure. It can solve the problems that the glue cannot be effectively filled, cannot adapt to stress, and device damage, so as to improve the application reliability and reliability. Stability, improve the resistance to high overload, avoid the effect of device failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

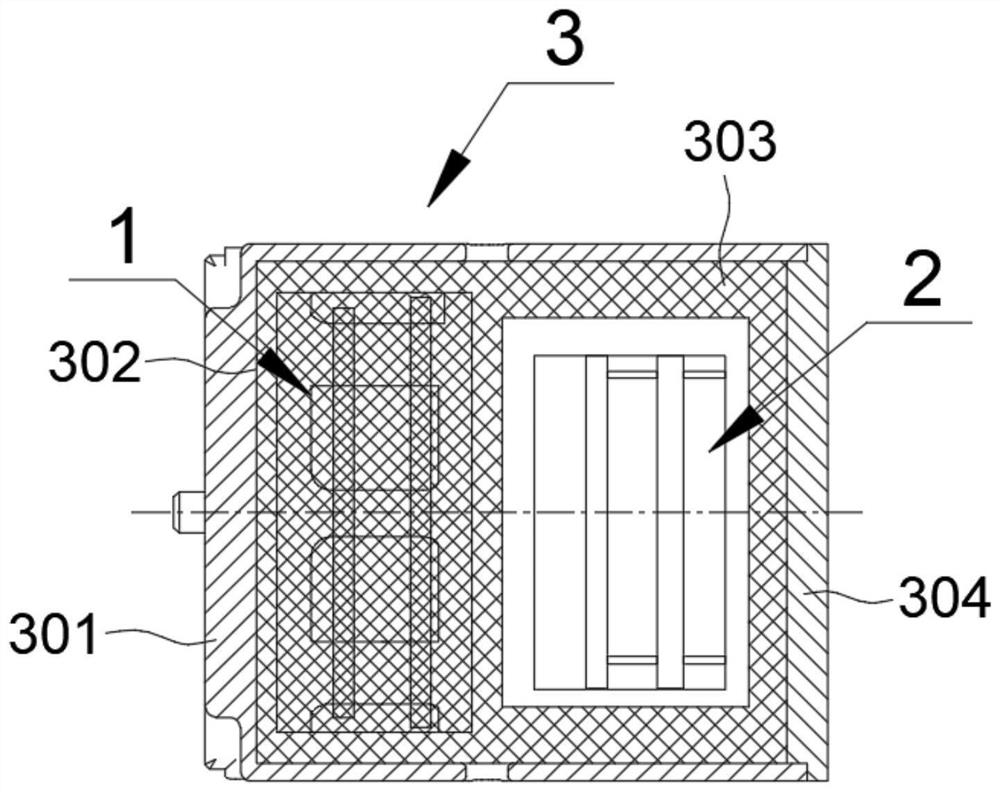

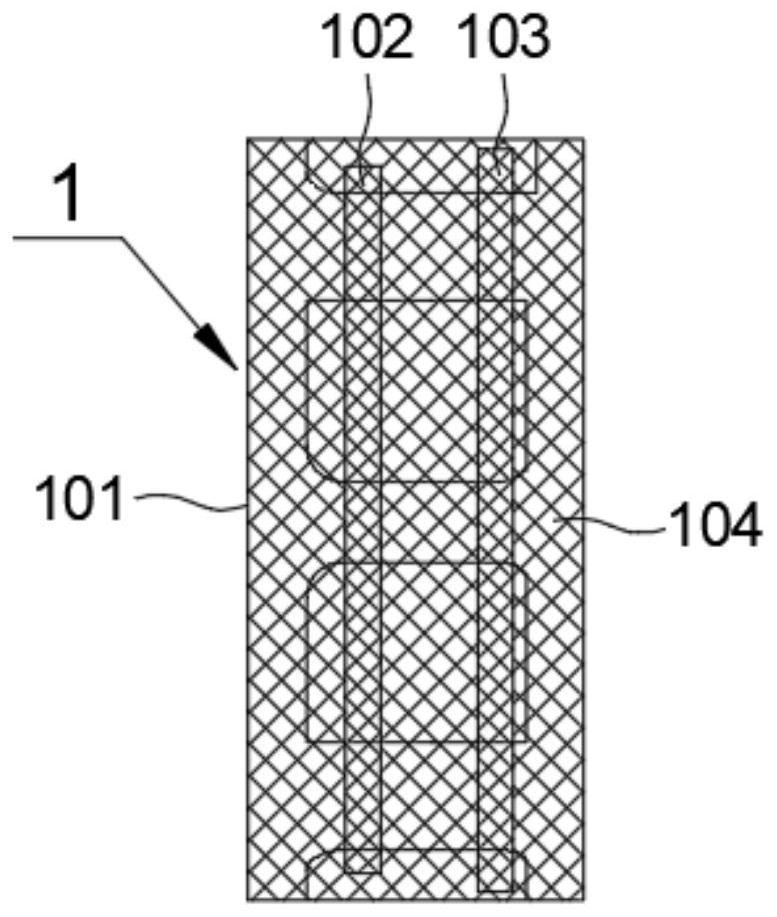

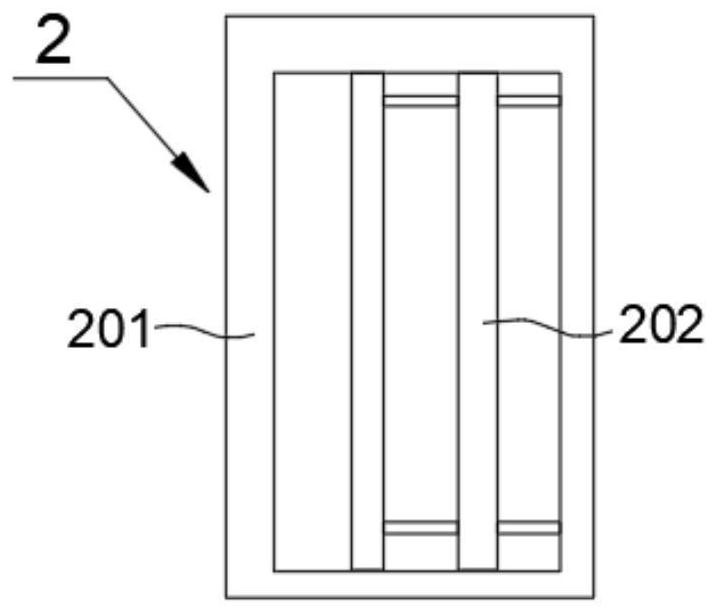

[0058] see Figure 1 ~ Figure 3 In the preferred embodiment of the present invention, the data link device suitable for high overload shock environment includes a housing assembly 3 and a low frequency module 1 and a high frequency module 2 packaged in the housing assembly 3 . Among them, the low-frequency module 1 and the high-frequency module 2 are arranged independently of each other in the housing assembly 3, and are respectively used to accommodate the low-frequency part assembly and the high-frequency part assembly in the data link device, so that the low-frequency part assembly and the high-frequency part assembly can be in the The device is separated during installation, thereby ensuring that the two modules can ensure the reliability and stability of the components in the module when the device is subjected to high overload impact.

[0059] Specifically, the low frequency module 1 in the preferred embodiment is as figure 2 As shown in , it includes a first inner cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com