Remote monitoring method and device for production waste, computer equipment and storage medium

A technology for remote monitoring and production equipment, applied in computer parts, computing, electronic waste recycling, etc., can solve the problems of difficult supervision, high consumption of manpower and material resources, low efficiency, etc., to reduce the difficulty of supervision, ensure accuracy, improve Effects of Regulatory Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

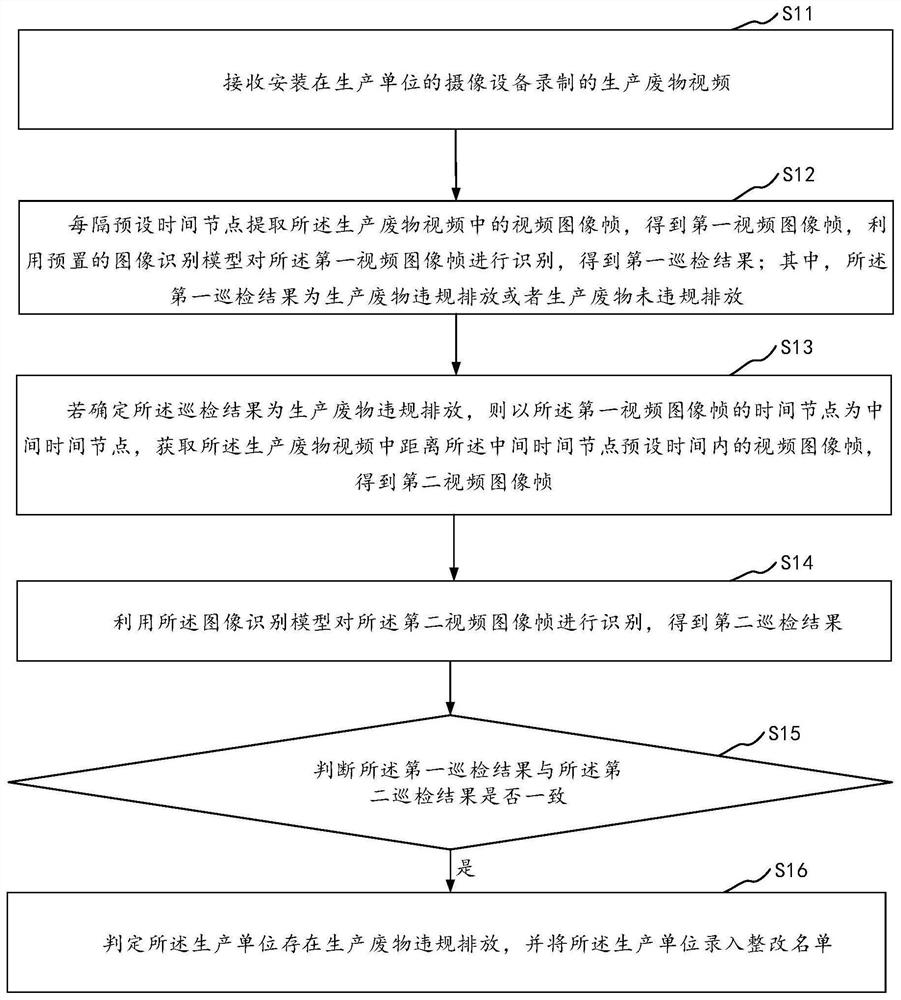

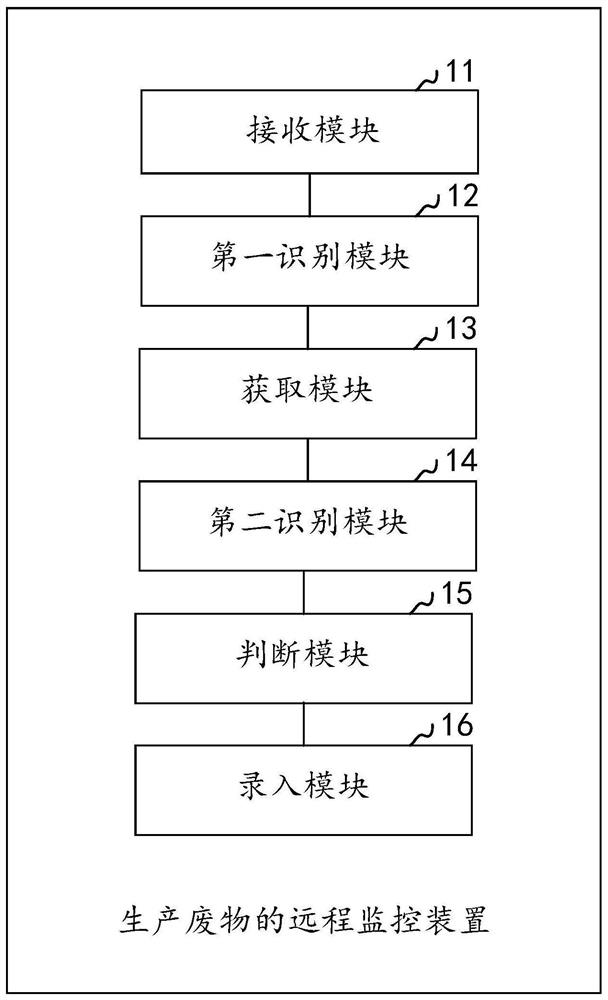

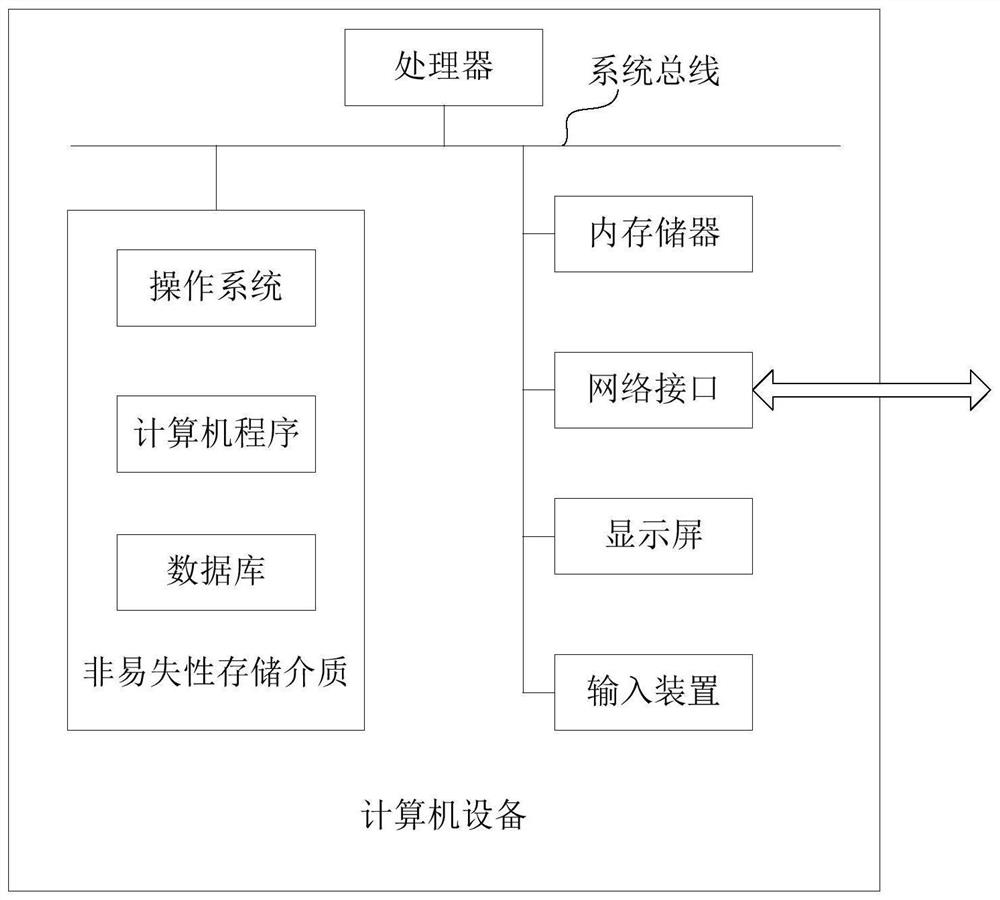

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the purpose, technical solution and advantages of the present application clearer, the present application will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present application, and are not intended to limit the present application.

[0052] The current field of production waste supervision is still in the semi-intelligent stage. For example, production waste data will be entered into the supervision system, but remote supervision cannot be achieved. For example, the declaration of production waste discharge requires the production unit to register with the supervision department. Departments still need to go to the field to monitor the production waste on a regular basis, and law enforcement departments face many difficulties in collecting evidence of violations. These make it impossible to trace produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com