Pressure stabilizing air-floating type liquid crystal display screen with vibration reduction and impact resistance functions

A liquid crystal display, floating technology, applied in the direction of electrical components, electrical equipment shell/cabinet/drawer, instruments, etc., can solve the problem of irrecoverable damage of liquid crystal screen, achieve compact structure, reasonable design, improve anti-vibration level Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

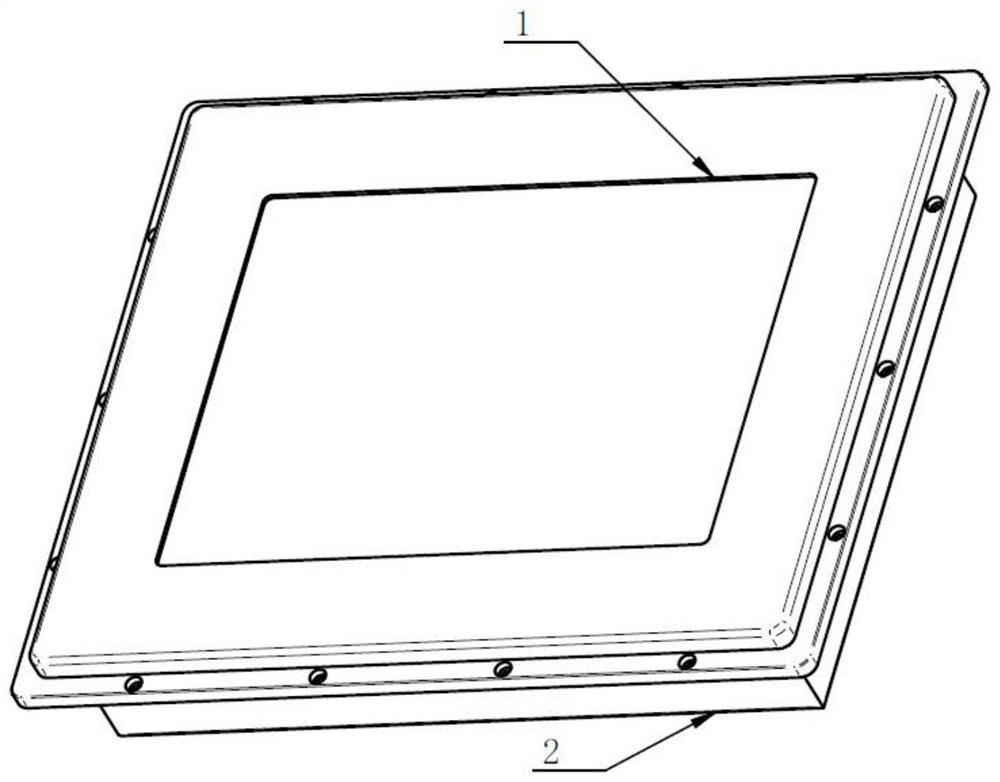

[0028] A liquid crystal screen based on a stabilized air float, such as figure 1 As shown, it includes the front panel assembly (1) and the rear shell (2) installed together.

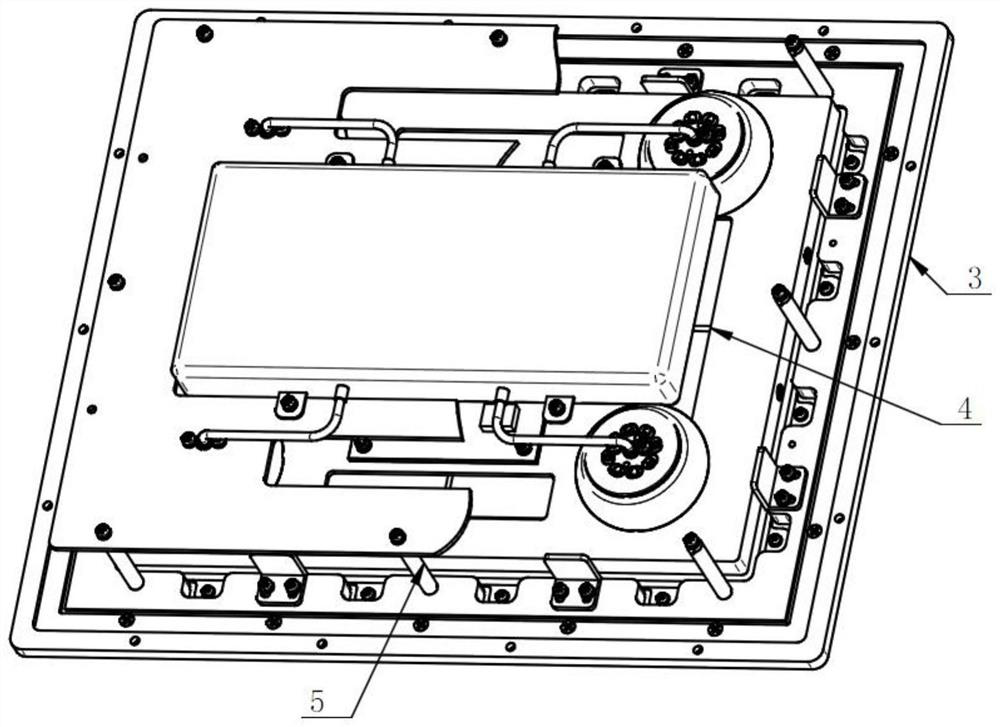

[0029] Such as figure 2 As shown, the front panel assembly (1) includes a front shell assembly (3), an internal screen core assembly (4), and screen mounting studs (5), and the internal screen core assembly (4) passes through the screen mounting studs (5) Install on the inside of the front case assembly (3).

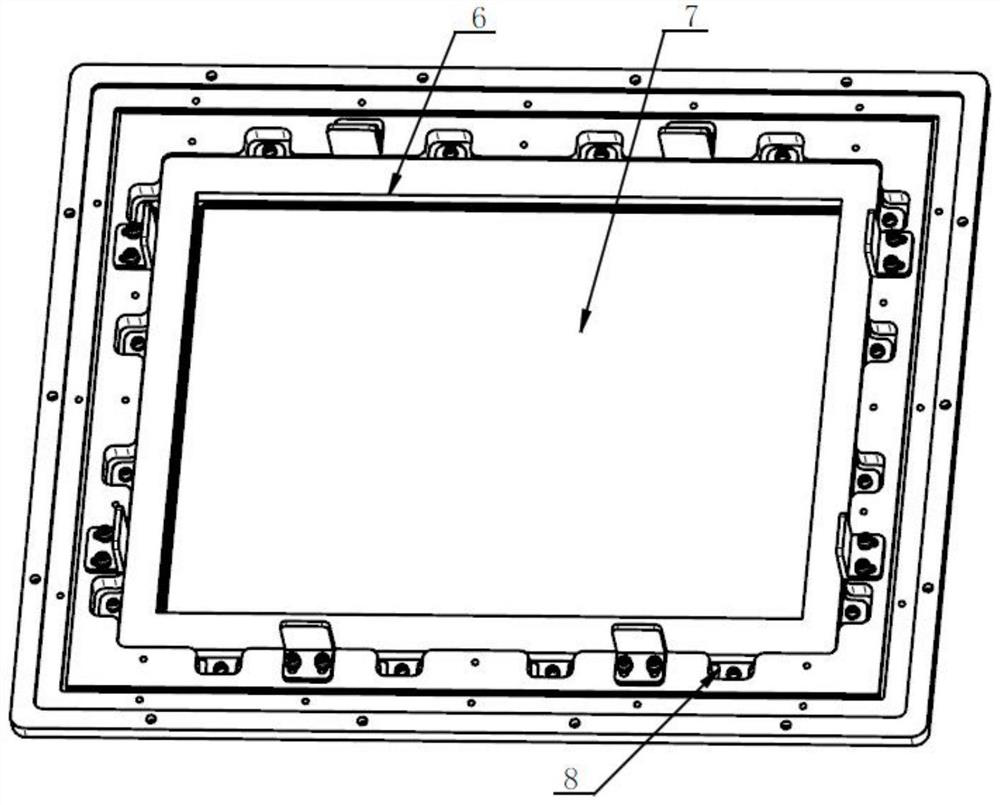

[0030] Such as image 3 As shown, the front shell assembly (3) is mainly composed of the screen front panel, anti-collision cotton (6), shielding glass (7) and glass pressure frame (8). The shielding glass (7) is fixed on the front panel of the screen through a glass pressure frame (8), and the anti-collision cotton (6) is coated with 3M glue on one side and b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com