Optical lens ink coating device

An optical lens and ink coating technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of uneven coating and low work efficiency, and achieve the effect of improving precision and reducing the emission of peculiar smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

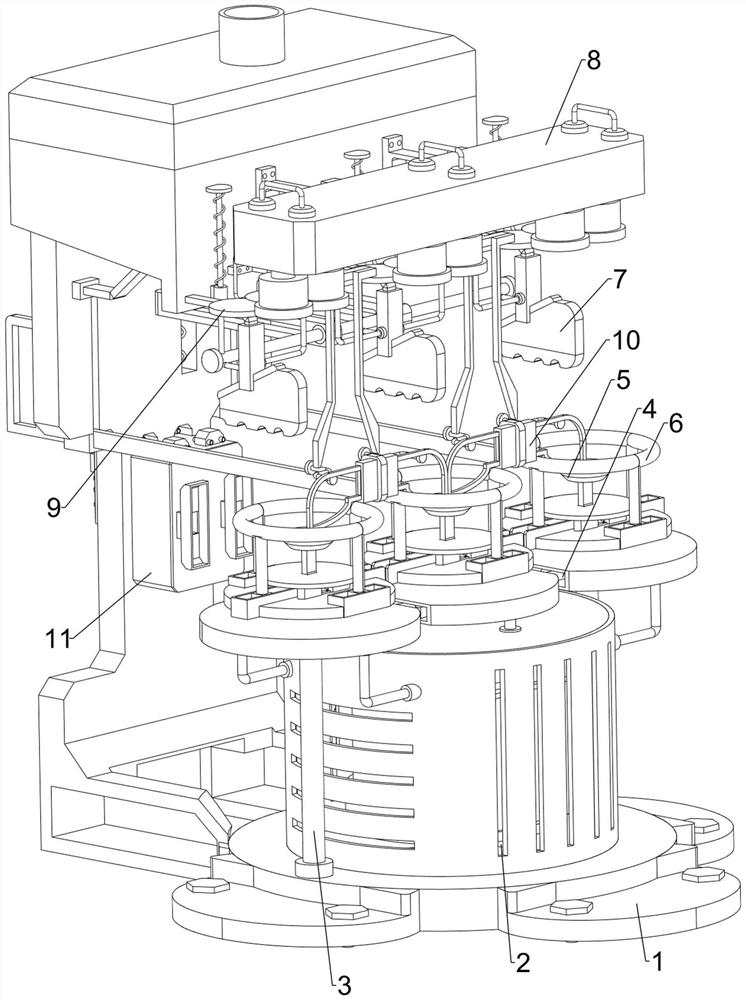

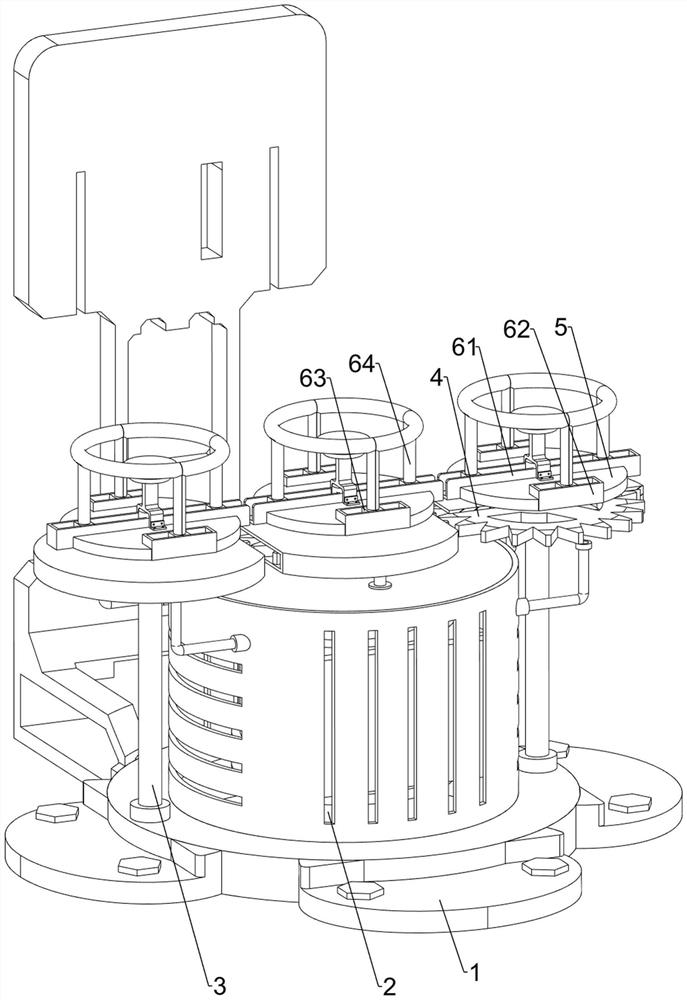

[0062] An optical lens ink coating device, such as Figure 1-4 As shown, it includes a mounting frame 1, a reduction motor 2, a vertical rod 3, a gear 4, a placement seat 5, a clamping assembly 6 and an ink application assembly 7. A reduction motor 2 is provided on the front side of the top of the mounting frame 1. Both left and right sides of the upper part are equipped with a vertical rod 3, and the upper part of the vertical rod 3 and the output shaft of the reduction motor 2 are provided with a gear 4, and the two adjacent gears 4 are meshed with each other, and the top of the vertical rod 3 is connected to the output shaft of the reduction motor 2. The output shaft is provided with a placement seat 5, and the placement seat 5 is provided with a clamping assembly 6 that can fix the lens, and the upper side of the mounting frame 1 rear is provided with an inking assembly 7 that applies ink to the lens.

[0063] When the optical lens needs to be coated with ink, the staff fi...

Embodiment 2

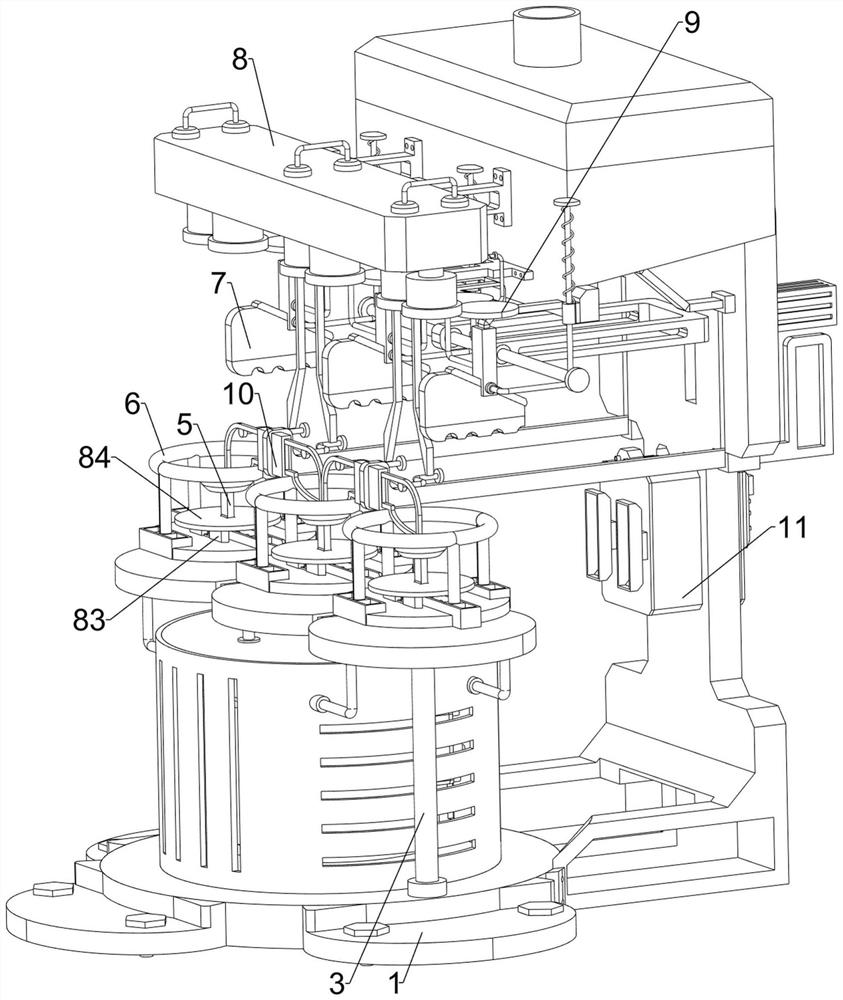

[0069] On the basis of Example 1, such as figure 1 , figure 2 , Figure 5 , Image 6 and Figure 7 As shown, a test assembly 8 is also included. The test assembly 8 includes an electric storage box 81, a measuring lamp 82, a fixed block 83 and a radiation plate 84. Three groups of measuring lamps 82 are arranged horizontally on the lower side of the box 81, and each group is composed of two measuring lamps 82 on the left and right. The top of the long guide rail 61 is provided with a fixed block 83, and the top of the fixed block 83 is provided with a radiation plate 84. The radiation plate 84 Sleeved on the placement seat 5 , the radiation plate 84 corresponds to each group of measuring lamps 82 .

[0070] When the lens is coated with ink, turn on the measurement lamp 82, and the power storage box 81 supplies power to the measurement lamp 82. After the lens is coated with ink, the light of the measurement lamp 82 passes through the lens and shines on the radiation plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com