Sand and stone automatic and equivalent screening device for civil engineering

A civil engineering, sand and gravel technology, applied in the field of quantitative screening devices, can solve the problems of time-consuming, laborious and low work efficiency, and achieve the effect of improving screening efficiency and avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

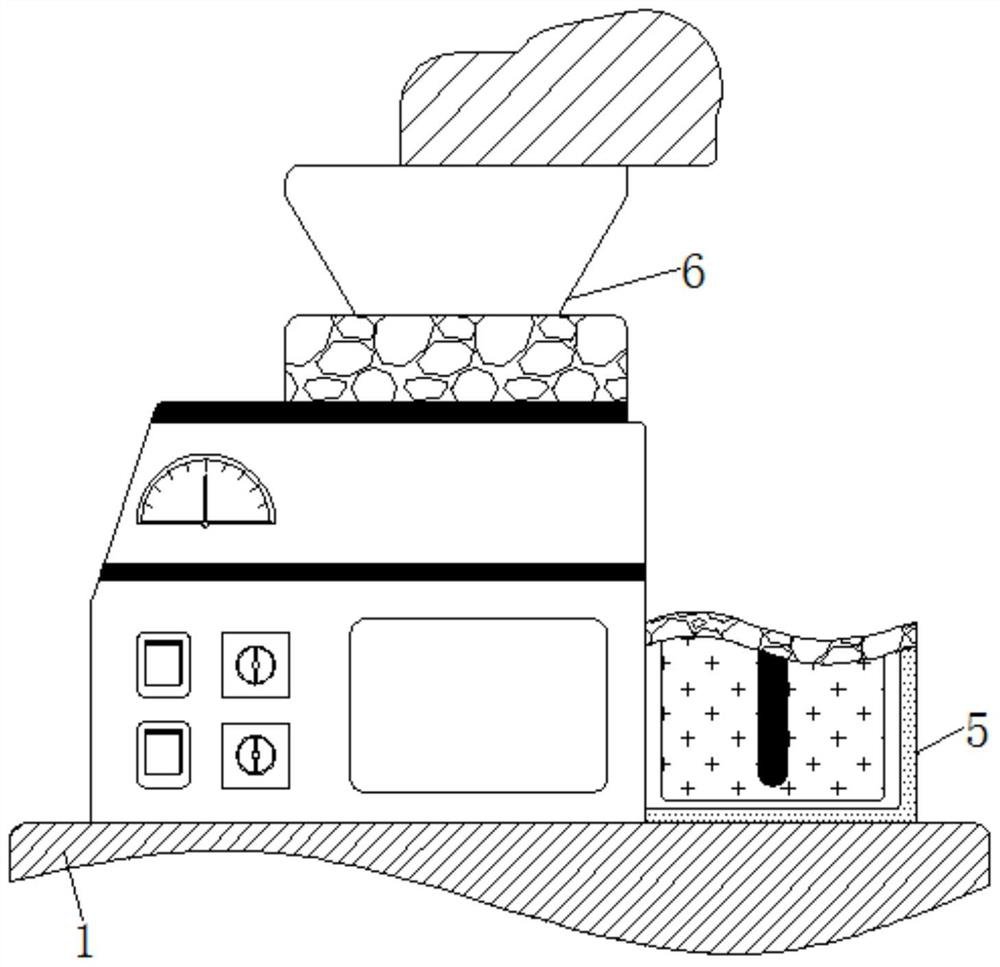

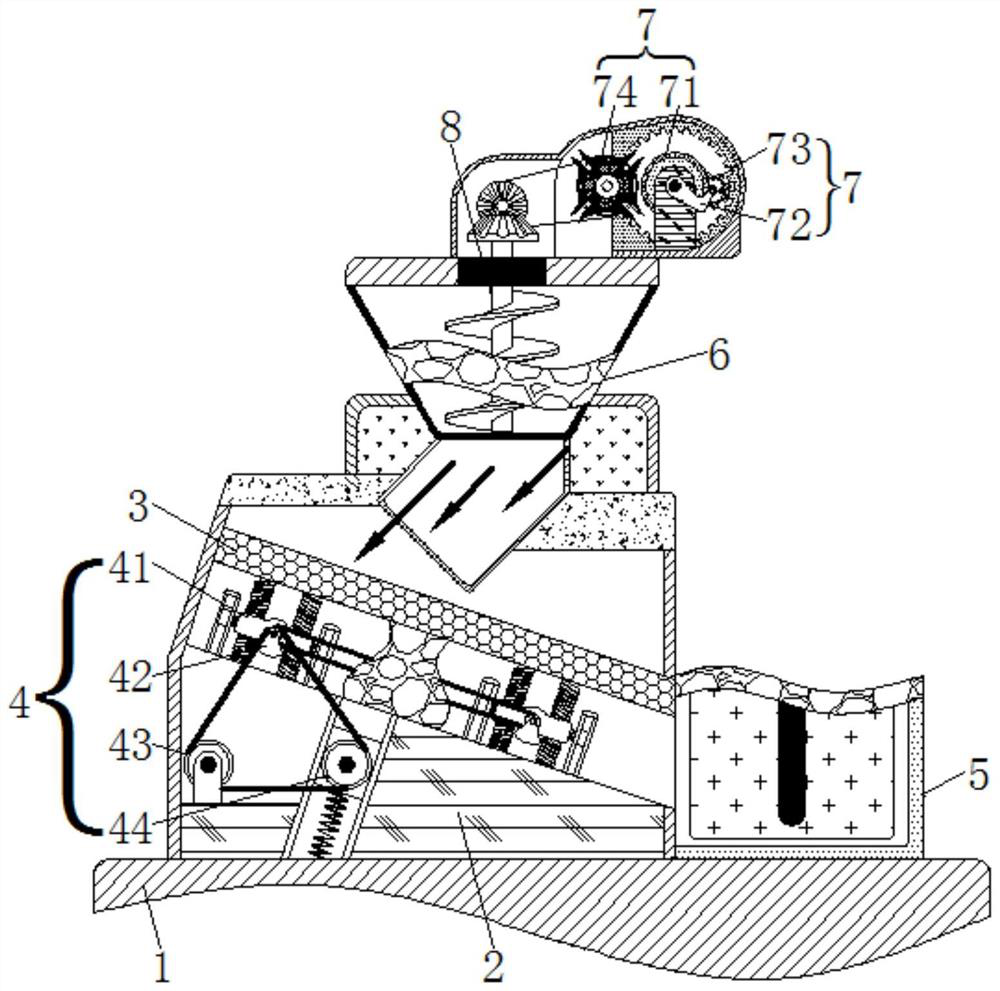

[0025] see Figure 1-3 , a device for automatic and equivalent screening of sand and gravel for civil engineering, including a base 1, and a sloping plate 2 is fixedly connected to the top of the base 1, so that the fine sand that has been screened is automatically transmitted along the sloping plate 2, and is collected in a unified manner. Inside the sand storage chamber 5, a sieve plate 3 is flexibly connected to the top of the slant plate 2, and the sieve plate 3 is used to automatically screen the fine sand. The size of the sand storage chamber 5 is compatible with each other, and the inclined setting can minimize blockage. The sand screening mechanism 4 is movably connected to the bottom of the sieve plate 3. The sand sifting mechanism 4 includes a limit rod 41, and the surface of the limit rod 41 is movably connected. There is a special-shaped disc 42, and the special-shaped disc 42 is set in an arc shape. At the same time, springs are arranged at the upper and lower end...

Embodiment 2

[0028] see Figure 1-3 , a device for automatic and equivalent screening of sand and gravel for civil engineering, including a base 1, and a sloping plate 2 is fixedly connected to the top of the base 1, so that the fine sand that has been screened is automatically transmitted along the sloping plate 2, and is collected in a unified manner. Inside the sand storage chamber 5, a sieve plate 3 is flexibly connected to the top of the slant plate 2, and the sieve plate 3 is used to automatically screen the fine sand. The size of the sand storage chamber 5 is compatible with each other, and the inclined setting can minimize blockage. The bottom of the sieve plate 3 is movably connected with the sand screening mechanism 4, the top of the base 1 is fixedly connected with the sand storage chamber 5, and the top of the sieve plate 3 is fixed. A feed chamber 6 is connected, and the feed chamber 6 is used for automatic feeding.

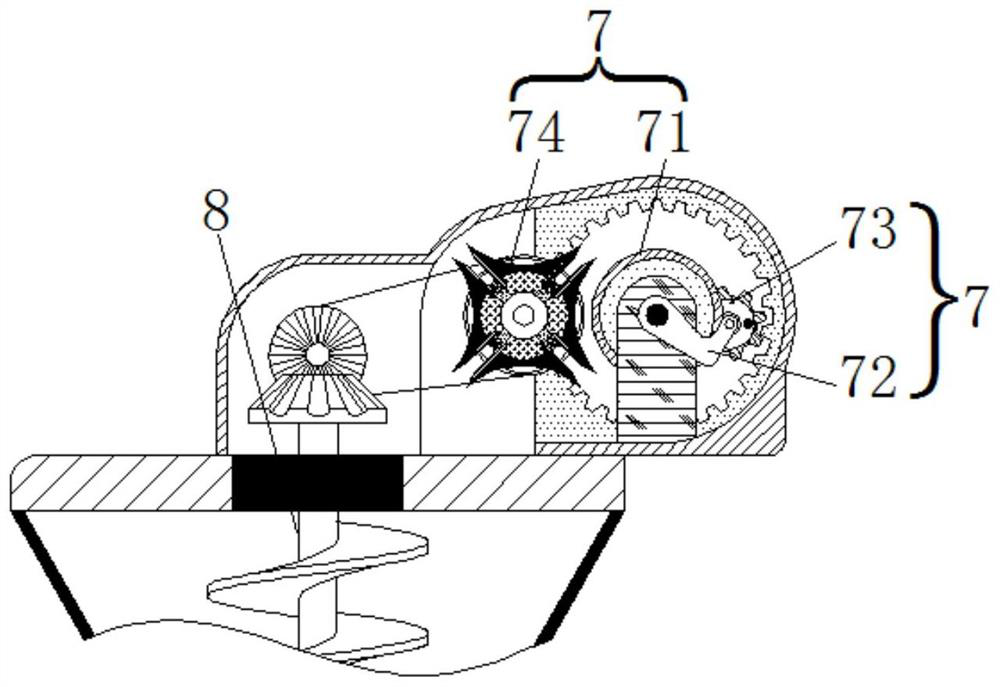

[0029] The top of the feeding chamber 6 is movably connect...

Embodiment 3

[0031] see Figure 1-3 , a device for automatic and equivalent screening of sand and gravel for civil engineering, including a base 1, and a sloping plate 2 is fixedly connected to the top of the base 1, so that the fine sand that has been screened is automatically transmitted along the sloping plate 2, and is collected in a unified manner. Inside the sand storage chamber 5, a sieve plate 3 is flexibly connected to the top of the slant plate 2, and the sieve plate 3 is used to automatically screen the fine sand. The size of the sand storage chamber 5 is compatible with each other, and the inclined setting can minimize blockage. The sand screening mechanism 4 is movably connected to the bottom of the sieve plate 3. The sand sifting mechanism 4 includes a limit rod 41, and the surface of the limit rod 41 is movably connected. There is a special-shaped disc 42, and the special-shaped disc 42 is set in an arc shape. At the same time, springs are arranged at the upper and lower end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com