LED assembling equipment

A technology for assembling equipment and modules, which is applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor cost, large workshop space, and low labor cost, and achieve low labor cost, small occupied length, and guaranteed The effect of assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

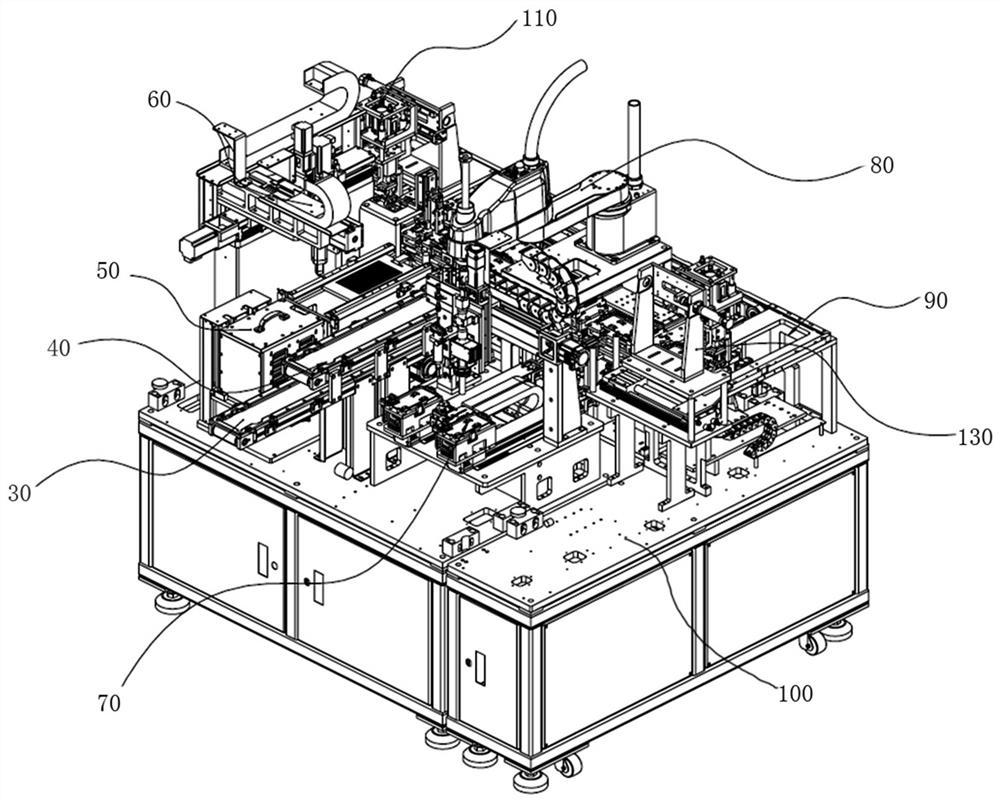

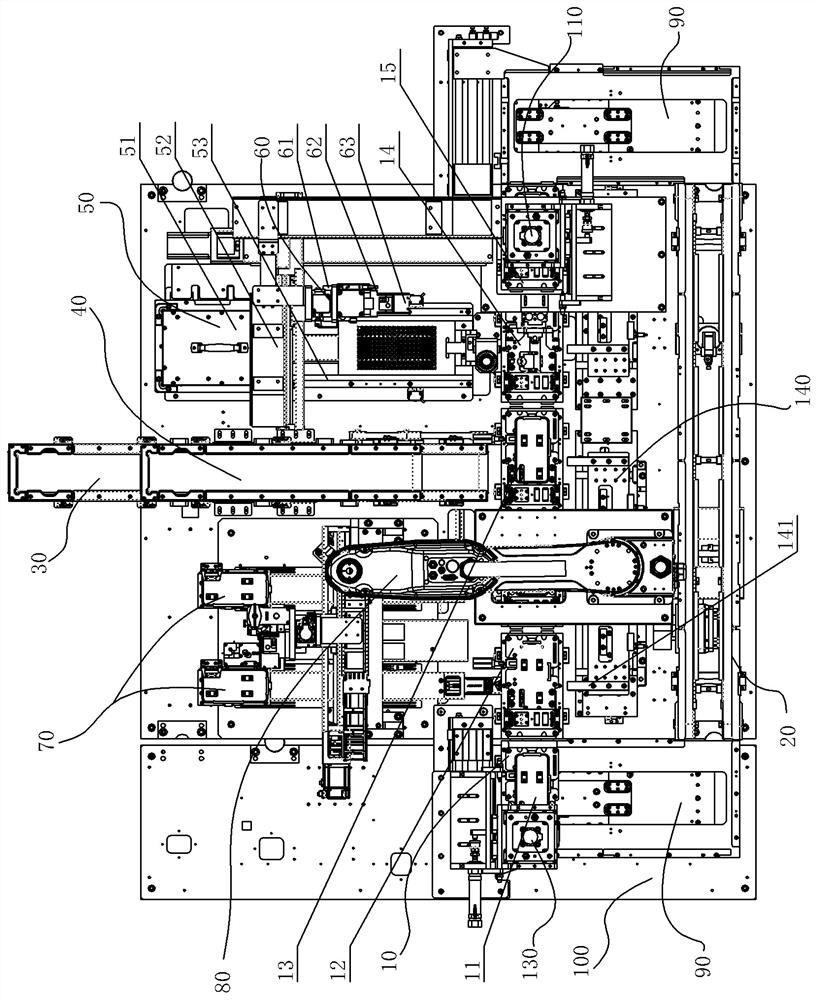

[0034] A kind of LED assembly equipment, see Figure 1-Figure 4 , which includes machine 100, jig main line 10, jig return line 20, mobile phone case feeding line 30, mobile phone case unloading line 40, LED feeding structure 50, LED assembly module 60, glue dispensing module 70. Mobile phone shell loading and unloading manipulator module 80;

[0035] One side of the machine 100 is arranged in parallel with the jig main line 10 and the jig return line 20, and the corresponding ends in the length direction of the jig main line 10 and the jig return line 20 respectively pass through the jig return handling module 90 connection and combination to form a closed fixture assembly line;

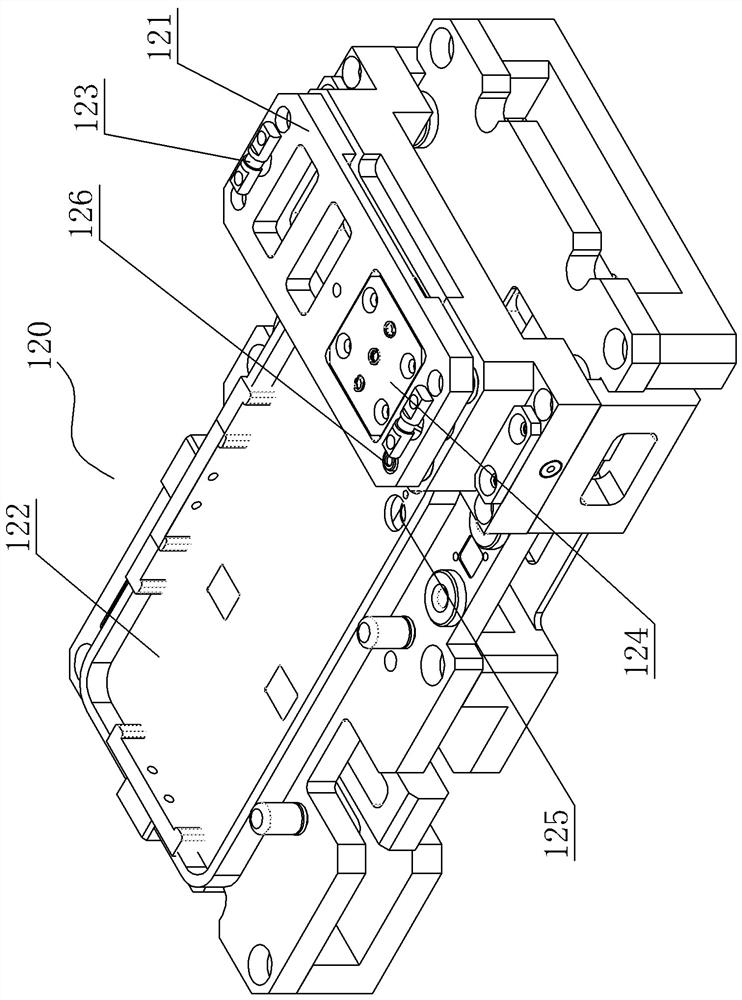

[0036] The traveling direction of the length direction of the fixture main line 10 is respectively provided with a fixture cover opening station 11, a mobile phone case finished product removal station 12, a mobile phone case putting station 13, an LED assembly station 14, and a fixture cover stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com