Three-dimensional skin sewing method

A sewing and three-dimensional technology, applied in the field of skin three-dimensional sewing, can solve problems such as difficulty in achieving partial three-dimensional soft effects, failure to meet customer needs, and single performance effect, and achieve beautiful effects, high seam quality, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

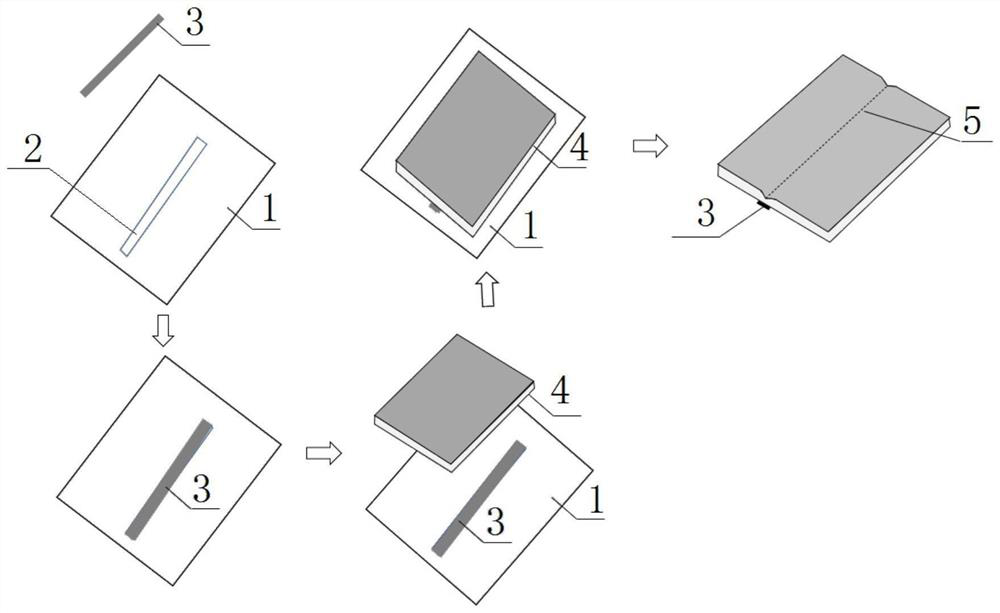

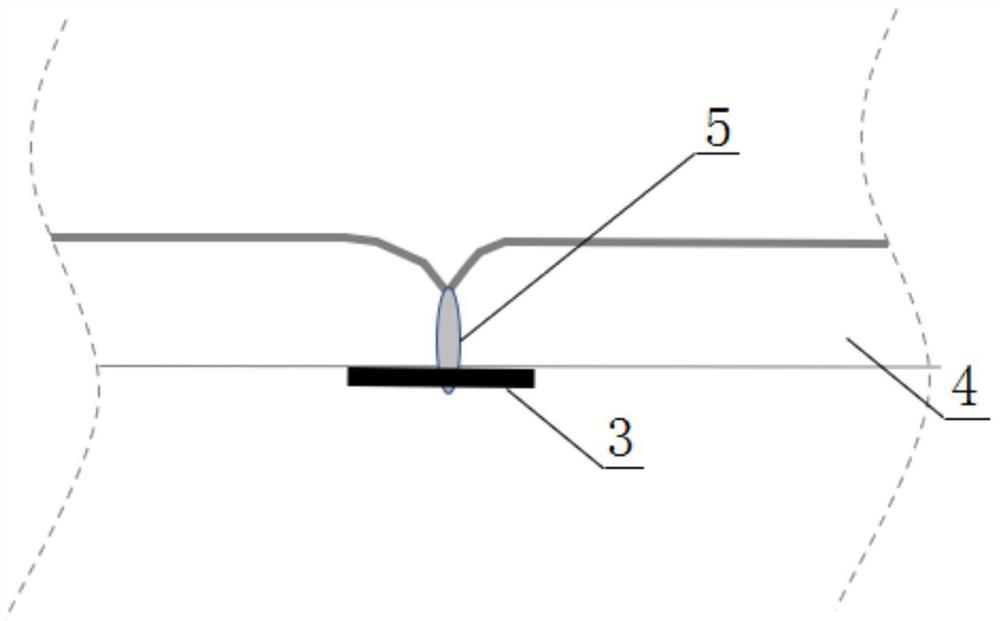

[0021] like figure 1 , figure 2 and image 3 Shown, a kind of epidermis three-dimensional sewing method of the present invention comprises the following steps:

[0022] A) Cut a strip-shaped groove 2 on the card board 1, place a non-woven gasket 3 in the groove 2, the shape of the groove 2 matches the shape of the non-woven gasket 3, and the non-woven fabric The thickness of the gasket 3 is 0.2mm, the width is 18mm, and the density of the non-woven gasket 3 is 200g / m 2 ;

[0023] B) Place a single piece of leather 4 on the card board 1 and fix it so that the leather 4 covers the non-woven gasket 3. The thickness of the leather 4 is 5mm. Using sewing equipment, the non-woven gasket 3 is covered by the stitching thread 5. Sewn to Leather 4;

[0024] C) Take out the leather 4 to realize the three-dimensional effect of the leather suture.

Embodiment 2

[0026] like figure 1 , figure 2 and image 3 Shown, a kind of epidermis three-dimensional sewing method of the present invention comprises the following steps:

[0027] A) Cut a strip-shaped groove 2 on the card board 1, place a non-woven gasket 3 in the groove 2, the shape of the groove 2 matches the shape of the non-woven gasket 3, and the non-woven fabric The thickness of the gasket 3 is 0.4mm, the width is 22mm, and the density of the non-woven gasket 3 is 300g / m 2 ;

[0028] B) Place a single piece of leather 4 on the card board 1 and fix it so that the leather 4 covers the non-woven gasket 3. The thickness of the leather 4 is 6 mm. Using sewing equipment, the non-woven gasket 3 is covered by the suture 5. Sewn to Leather 4;

[0029] C) Take out the leather 4 to realize the three-dimensional effect of the leather suture.

Embodiment 3

[0031] like figure 1 , figure 2 and image 3 Shown, a kind of epidermis three-dimensional sewing method of the present invention comprises the following steps:

[0032] A) Cut a strip-shaped groove 2 on the card board 1, place a non-woven gasket 3 in the groove 2, the shape of the groove 2 matches the shape of the non-woven gasket 3, and the non-woven fabric The thickness of the gasket 3 is 0.3mm, the width is 20mm, and the density of the non-woven gasket 3 is 250g / m 2 ;

[0033] B) Place a single piece of leather 4 on the card board 1 and fix it so that the leather 4 covers the non-woven gasket 3. The thickness of the leather 4 is 5.5 mm. Using sewing equipment, the non-woven gasket is covered by the stitching 5. 3 sewn onto the leather 4;

[0034] C) Take out the leather 4 to realize the three-dimensional effect of the leather suture.

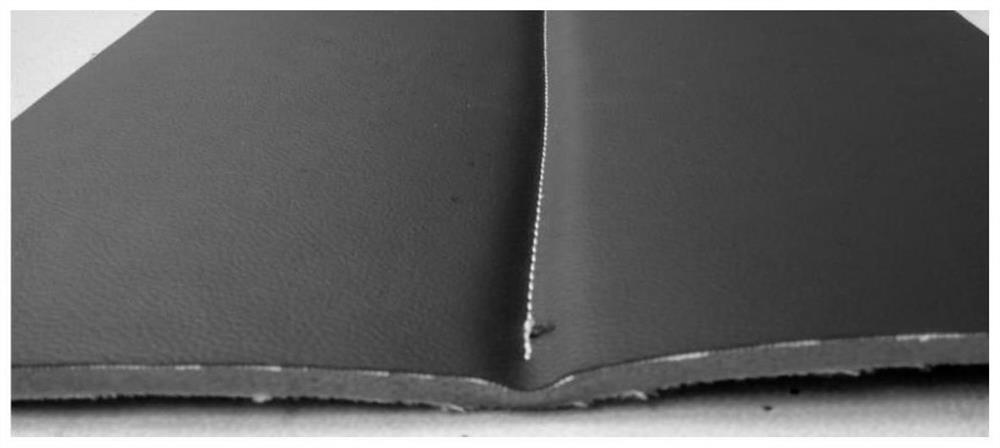

[0035] The three-dimensional sewing method for the skin of the present invention uses a piece of leather to realize the three-dimensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com