Hand-push type automatic road sweeper

A hand-push, sweeper technology, applied in road cleaning, cleaning methods, construction and other directions, can solve the problem of inability to enter the interior of the floor for cleaning, and achieve the effects of convenient dumping, convenient cleaning, and increased air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

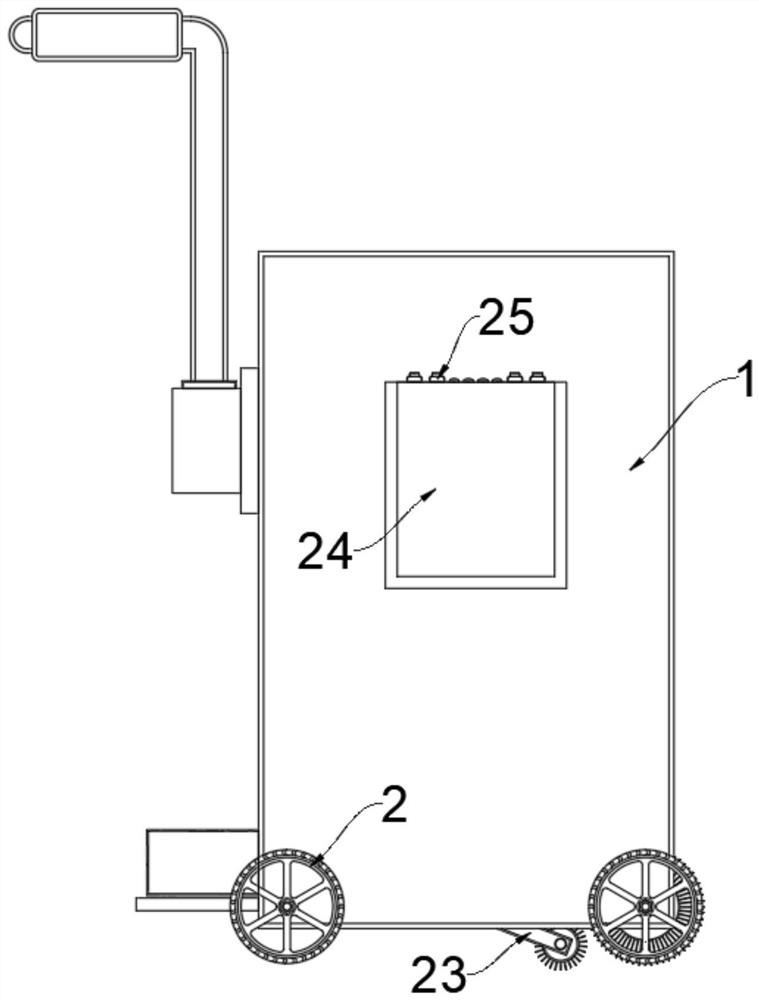

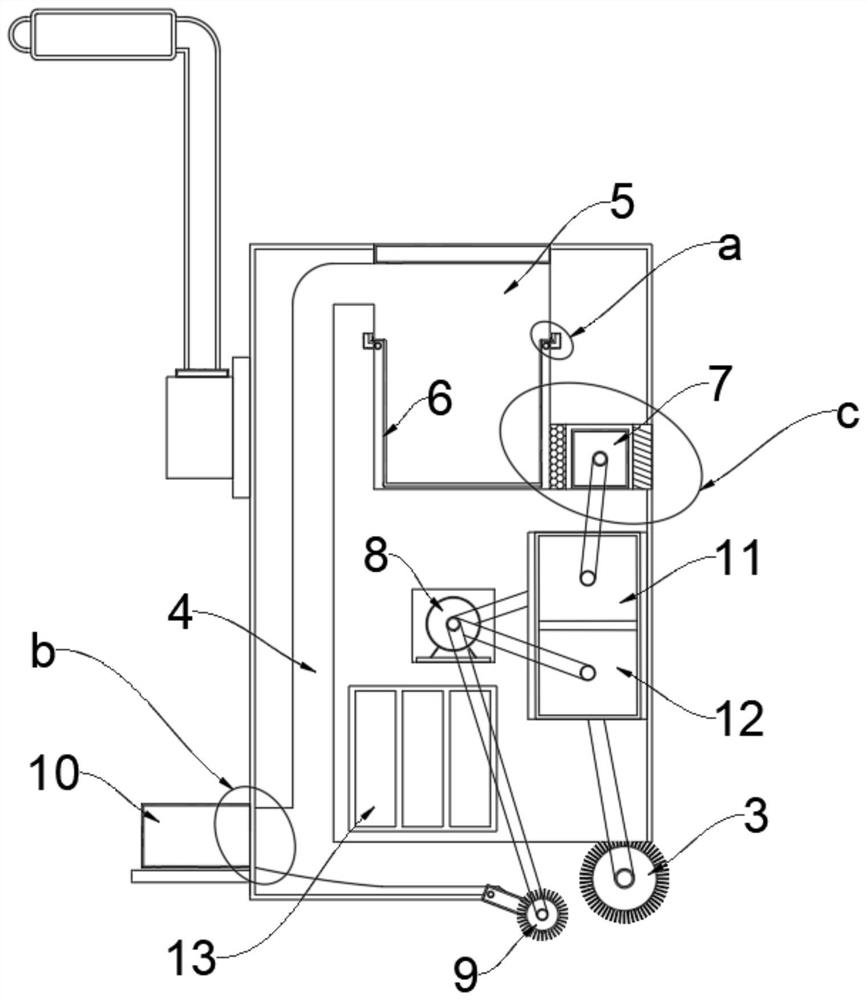

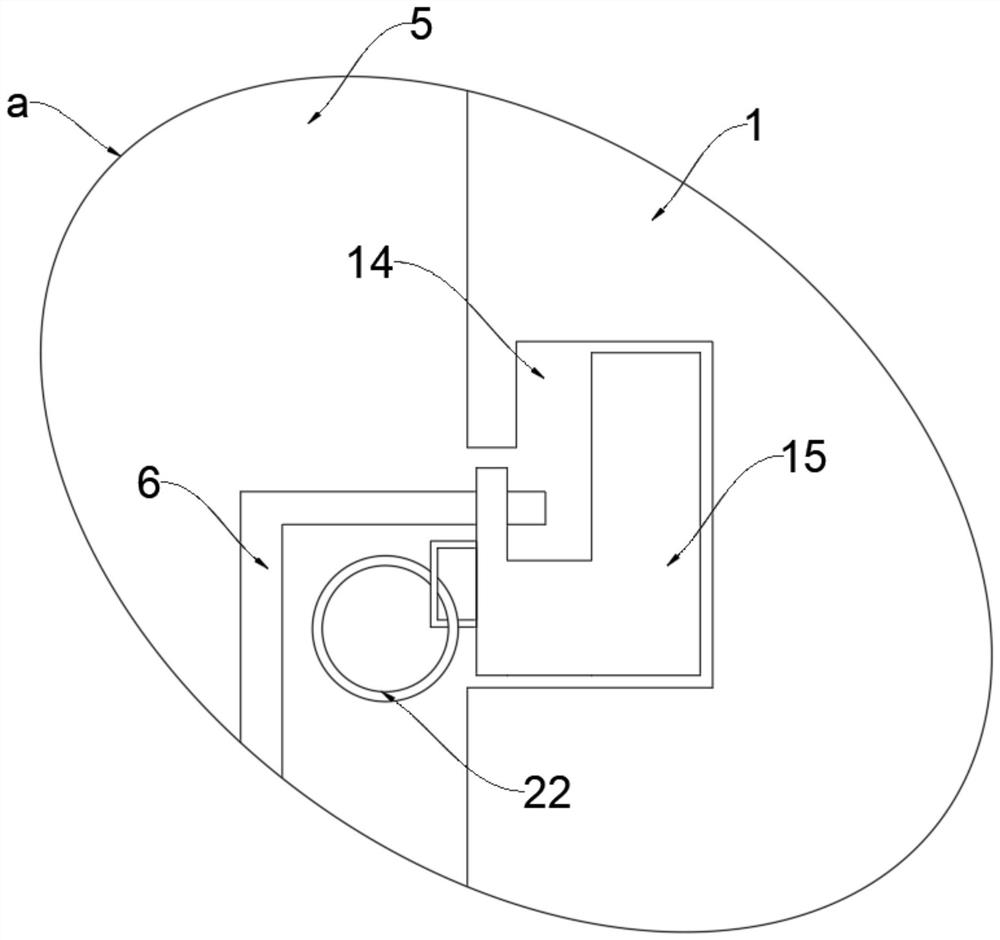

[0029] see Figure 1-6 , a hand-push automatic road sweeper, comprising a collection box 1, two sets of symmetrical moving wheels 2 are arranged on both sides of the bottom of the collection box 1, and the middle part of the moving wheels 2 on one side of the collection box 1 is rotatably connected with a cleaning Roller 3, the side of the collection box 1 away from the cleaning roller 3 is connected with a bulk collection box 10, the bulk collection box 10 communicates with the interior of the collection box 1, and the top of the collection box 1 is provided with a dust collection bin 5 and The outside of the bulk collection box 10 is connected, and the side of the bottom of the dust collection bin 5 is provided with a fan box 7, and the side of the fan box 7 away from the dust collection bin 5 is connected to the outside of the collection box 1. The collection box 1 The middle part is provided with a driving motor 8, and the transmission end of the driving motor 8 is connect...

Embodiment 2

[0032] This embodiment is an improvement made on Embodiment 1. For details, please refer to figure 2 , Figure 4 , the bottom surface of the collection box 1 is located inside the cleaning roller 3 and is provided with an inner rolling roller 9, the two ends of the inner rolling roller 9 are fitted with a diagonal strut 23, and the other end of the diagonal strut 23 is fixed on the inner side of the bottom surface of the collection box 1 , the inner winding roller 9 is in transmission connection with the drive motor 8 .

[0033] In this embodiment: the bottom surface of the collection box 1 is located at the inner winding roller 9 inside the cleaning roller 3, and the dust and stones swept into the bottom of the collection box 1 by the cleaning roller 3 can be swept into the inside of the collection box 1 in reverse, and transported to the collection box 1 and the inside of the bulk collection box 10, avoiding the accumulation of stones and dust in the middle of the collecti...

Embodiment 3

[0035] This embodiment is an improvement made on Embodiment 1. For details, please refer to figure 2 , between the drive motor 8 and the cleaning roller 3, a deceleration box 12 is provided, the drive end on one side of the deceleration box 12 is connected to the drive motor 8, and the transmission end on the other side of the deceleration box 12 is connected to the cleaning roller 3 drive connections.

[0036] In this embodiment: the deceleration box 12 that is provided with between the driving motor 8 and the cleaning roller 3 can reduce the rotating speed of the driving motor 8, so as to prevent the driving motor 8 from driving the cleaning roller 3 to rotate too fast, causing the cleaning roller 3 to spin. Damage, while effectively controlling the movement speed of the movement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com