Detachable electronic atomization device

An electronic atomization device, detachable technology, applied in applications, tobacco, smoker supplies, etc., can solve the problems of poor environmental protection, atomization components and oil tank parts cannot be disassembled and replaced, and increase the cost of use, etc., to achieve improved The effect of using environmental protection, improving stability and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

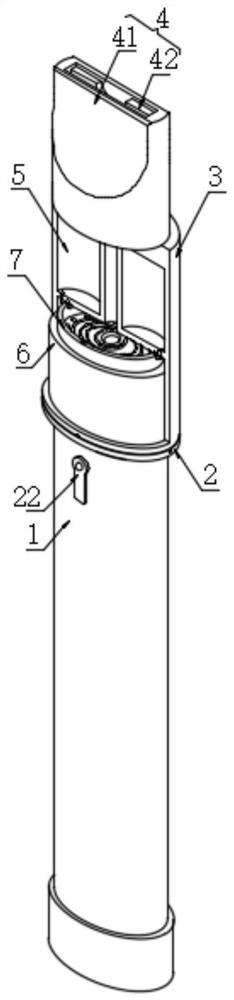

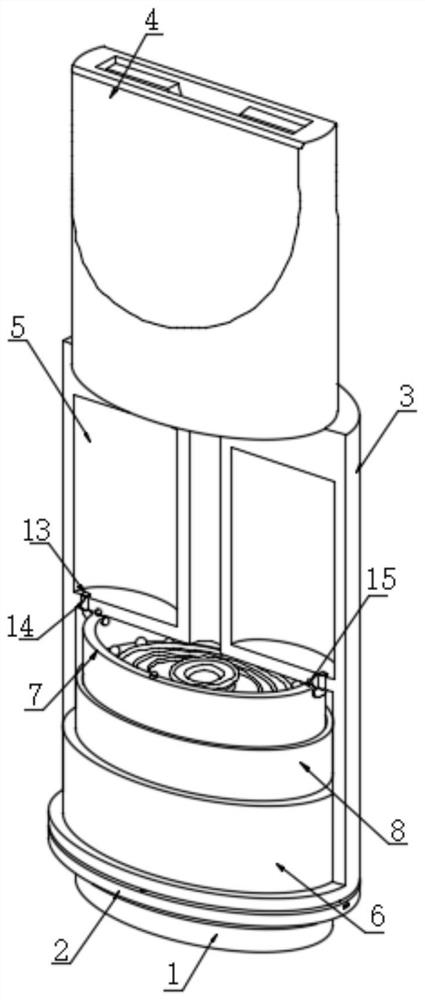

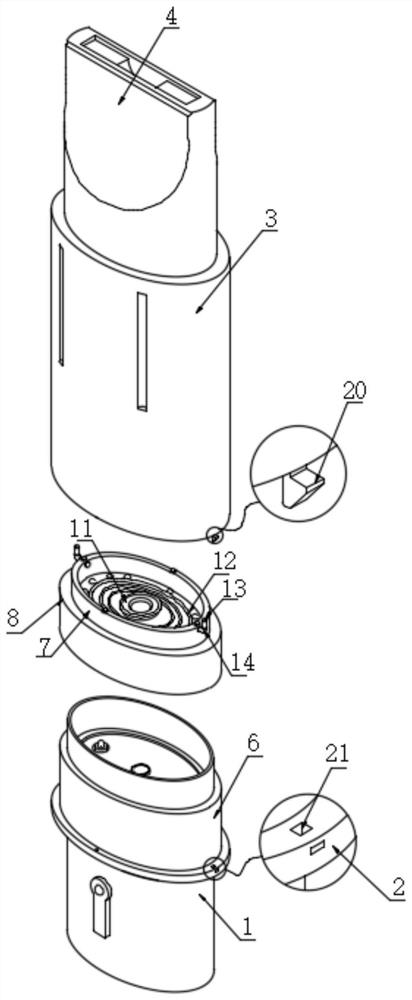

[0029] Such as Figure 1-6 As shown, the present invention provides a technical solution: a detachable electronic atomization device, including a battery rod 1, the top of the outer wall of the battery rod 1 is fixedly connected to the inner surface of the connecting seat 2, and the outer wall of the connecting seat 2 A connection sleeve 3 is provided, the top of the connection sleeve 3 is fixedly connected to the lower surface of the air suction assembly 4, the air suction assembly 4 communicates with the connection sleeve 3, the left and right sides of the connection sleeve 3 are provided with oil storage bins 5, and the battery The top end of the rod 1 is fixedly connected to the lower surface of the card holder 6, and the holder 6 is provided with a support seat 8, and the lower surface of the support seat 8 is fixedly connected to the top end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com