Kettle cover and heat preservation kettle

A pot lid and pot body technology, which is applied in the field of pot lids and thermos pots, to achieve good heat preservation effect, easy operation, and improved sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

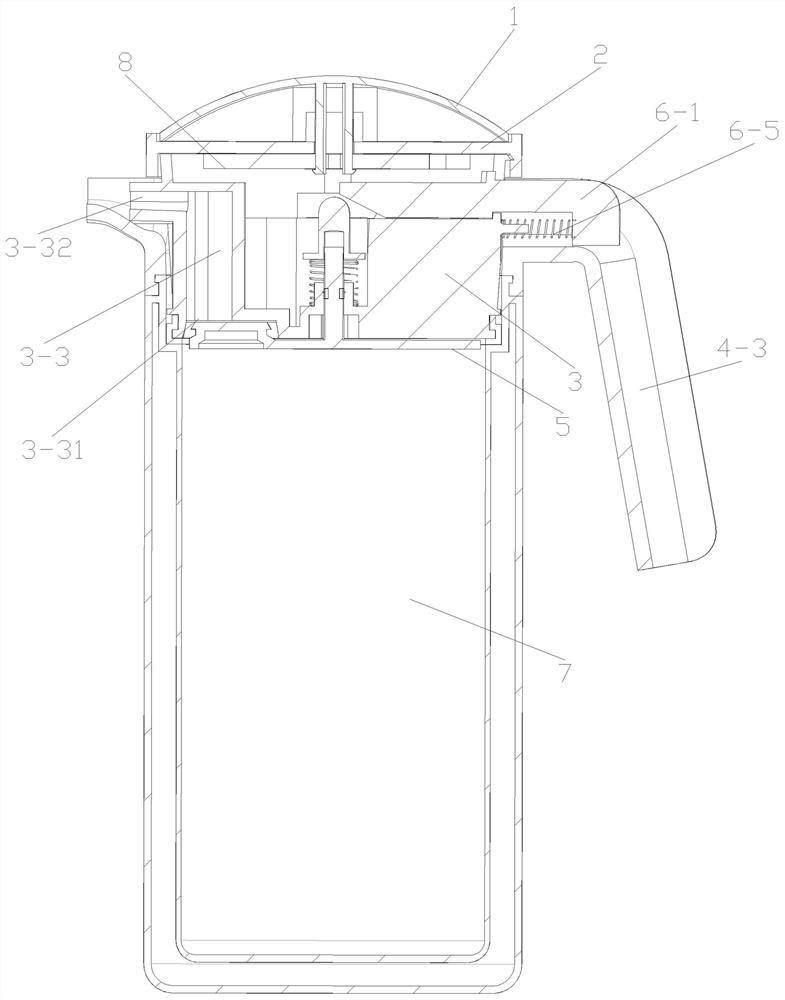

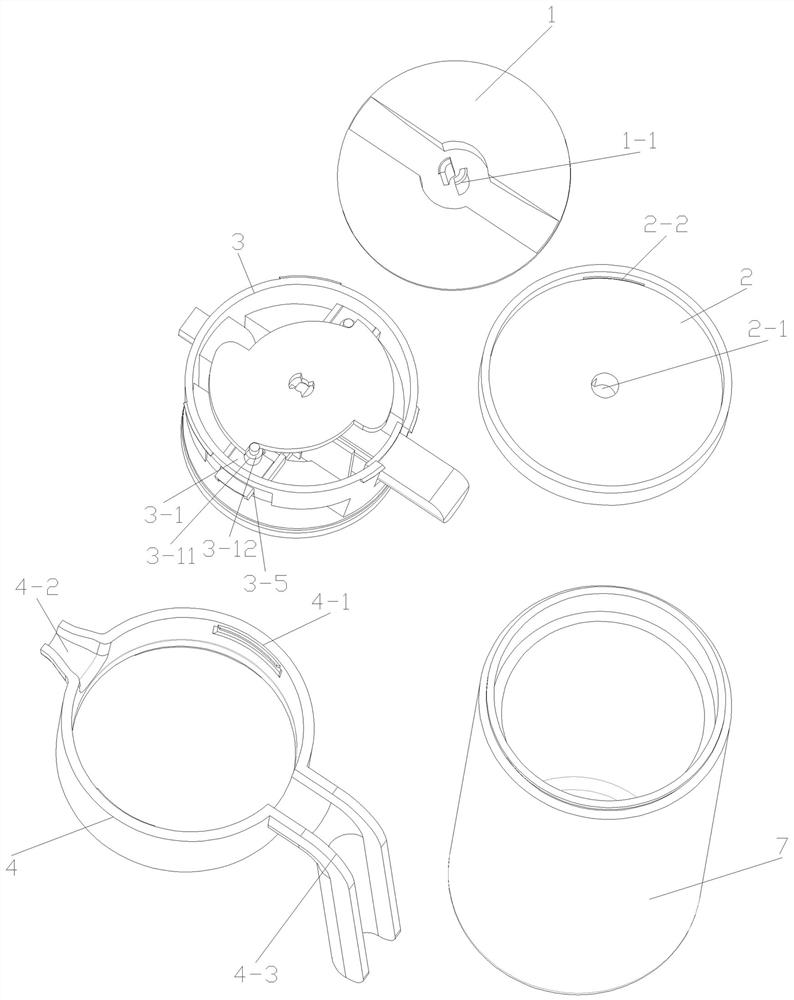

[0032] Such as Figure 1 to Figure 2 As shown in , the thermos pot of the present invention includes a pot body 7 and a pot cover. The pot body 7 is made of double-layer stainless steel, and a vacuum is drawn between the two layers of stainless steel to eliminate the heat transfer of the air medium and improve the heat preservation effect. The upper end is provided with a buckle structure, and a stepped surface is also provided on the inner wall of the upper end of the kettle body 7 .

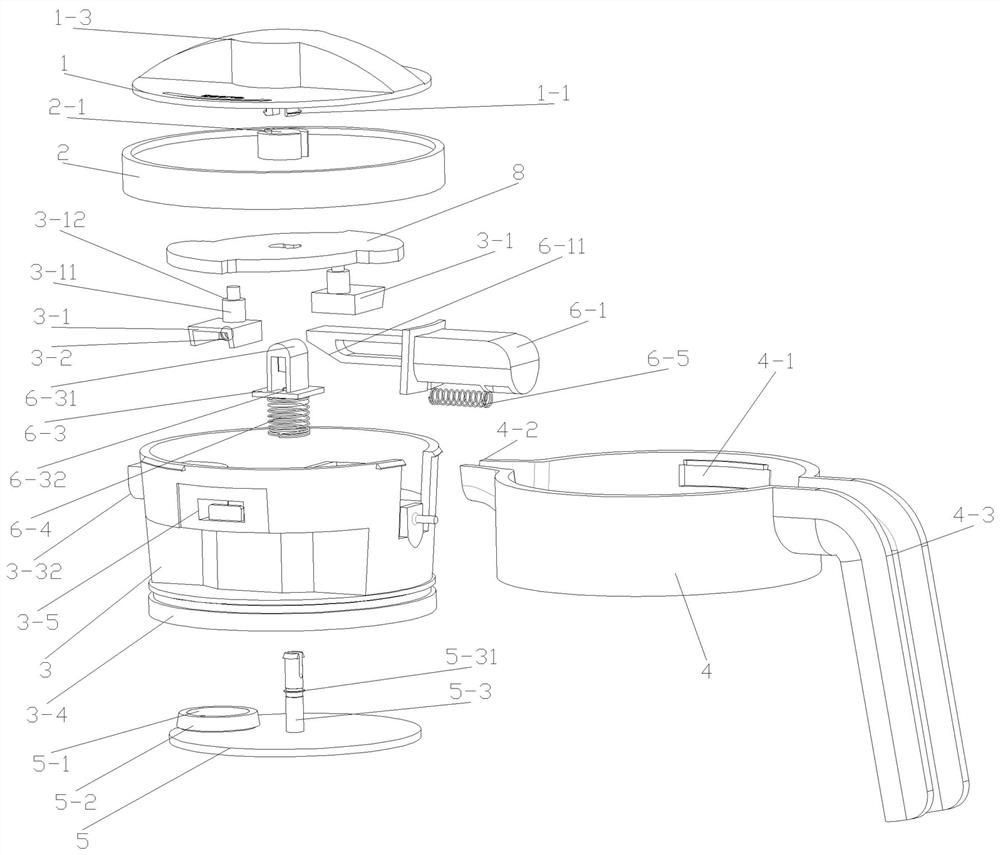

[0033] Such as figure 2 and image 3 As shown in , the pot lid includes an upper cover 1, a support cover 2, a cam plate 8, a pot lid body 3, a sealing bottom plate 5 and a handle 4, and the lower end of the handle 4 is snap-connected with the upper end of the kettle body 7 (as shown in FIG. figure 1 As shown in ), the handle 4 is provided with a handle 4-3 and a spout 4-2, and the inner wall of the handle 4 is provided with two sliding buckle slots 4-1 opposite to each other. The pot lid b...

Embodiment 2

[0040] Such as Figure 5 As shown in , the difference between the thermos pot in this embodiment and Embodiment 1 is that the cam plate 8 is provided with an arc-shaped working hole 8-2 that drives the slider 3-1 to slide, and the two ends of the working hole 8-2 The locking end 8-21 and the abdication end 8-22 are arranged respectively, the distance between the locking end 8-21 and the center of the upper cover 1 is larger than that of the abdication end 8-22 from the center of the upper cover 1, and the cam disc 8 is arranged on the cam On the disc support surface 3-12, the upright column 3-11 is inserted in the working hole 8-2 upwards, and no reset elastic member is set between the slide button 3-1 and the pot lid body 3.

[0041] When the cam disc 8 rotates, the working hole 8-2 slides relative to the column 3-11, and when the locking end 8-21 gradually approaches the column 3-11, the hole wall of the working hole 8-2 gradually pushes the column 3-11 toward the slider Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com