Self-destruction needle cylinder for medicine blending

A self-destructing, syringe technology, applied in hypodermic injection devices, infusion sets, syringes, etc., can solve problems such as syringe pollution, health impact, needle accidental injury, etc., to prevent accidental touch injuries, prevent re-use, reduce wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

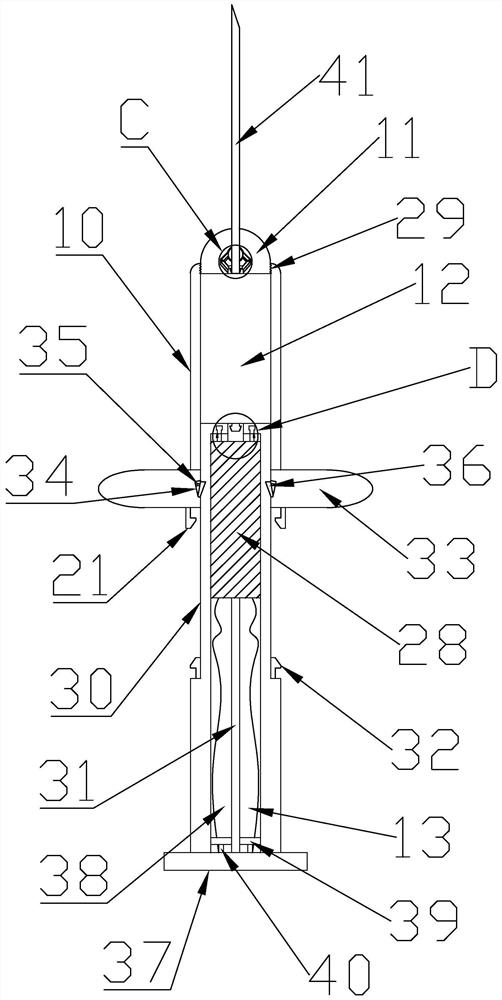

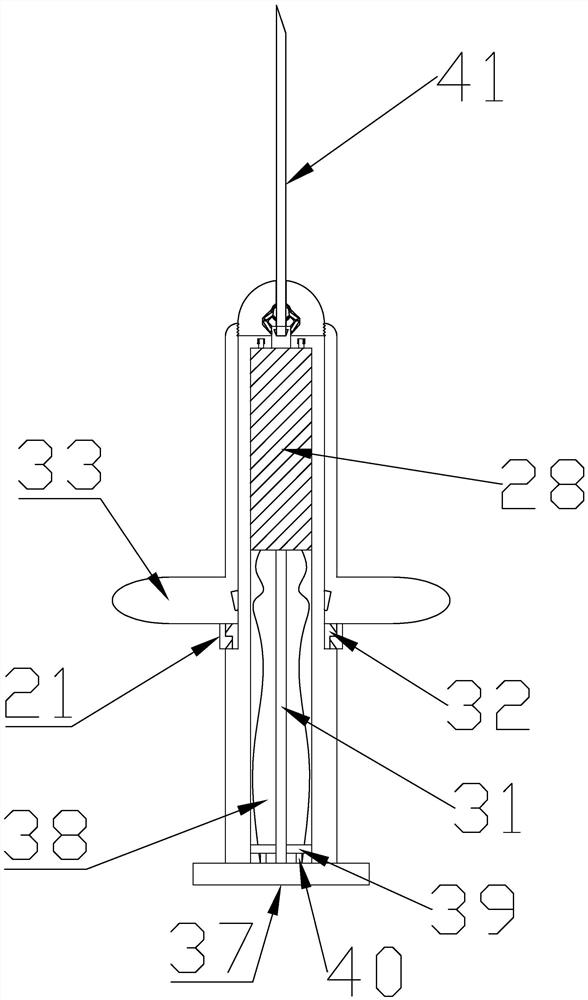

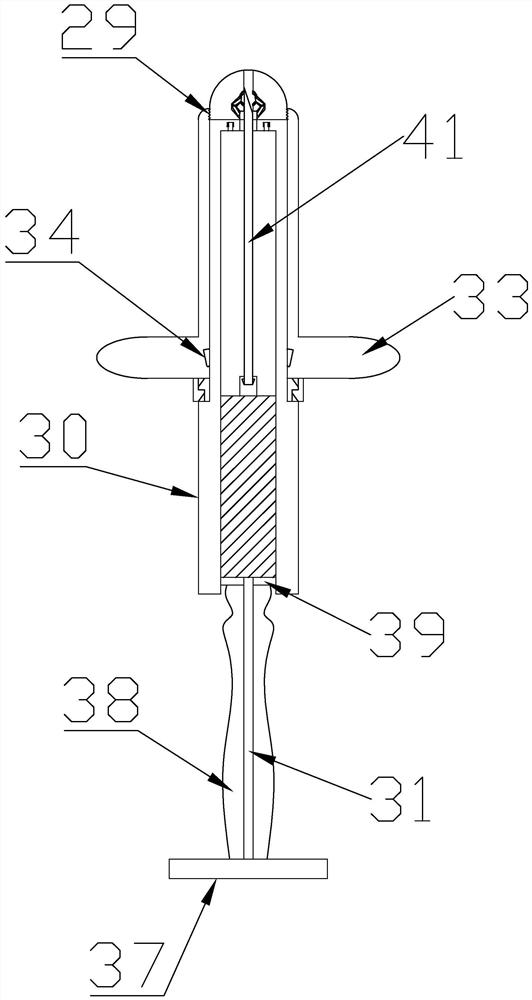

[0025] Such as figure 1 As shown, a self-destructing syringe for drug preparation includes a housing 10, a self-destructing needle cavity 11 is provided in the housing 10, a replaceable self-destructing needle is provided in the self-destructing needle cavity 11, and the self-destructing needle can be replaced. The needle is used to self-destruct the needle when the syringe is discarded, and the needle can be replaced according to the demand before use. The housing 10 is provided with an injection chamber 12, and the injection chamber 12 is provided with a syringe self-locking device, which is used for the syringe self-locking device. For the self-locking of the used syringe, the housing 10 is provided with an end pushing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com