Forming die for manufacturing computer shell

A technology of forming molds and computers, which can be applied to household appliances, other household appliances, applications, etc., can solve problems such as low molding quality, faults, and reduced work efficiency, so as to reduce air content, speed up injection efficiency, and avoid imaging defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

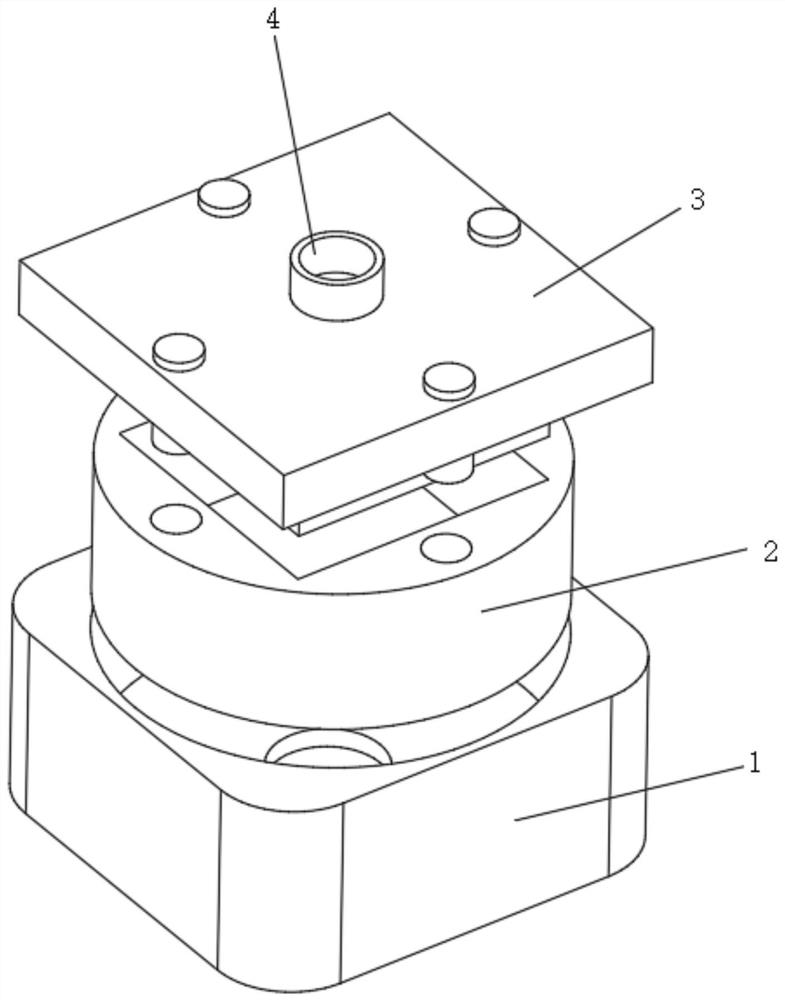

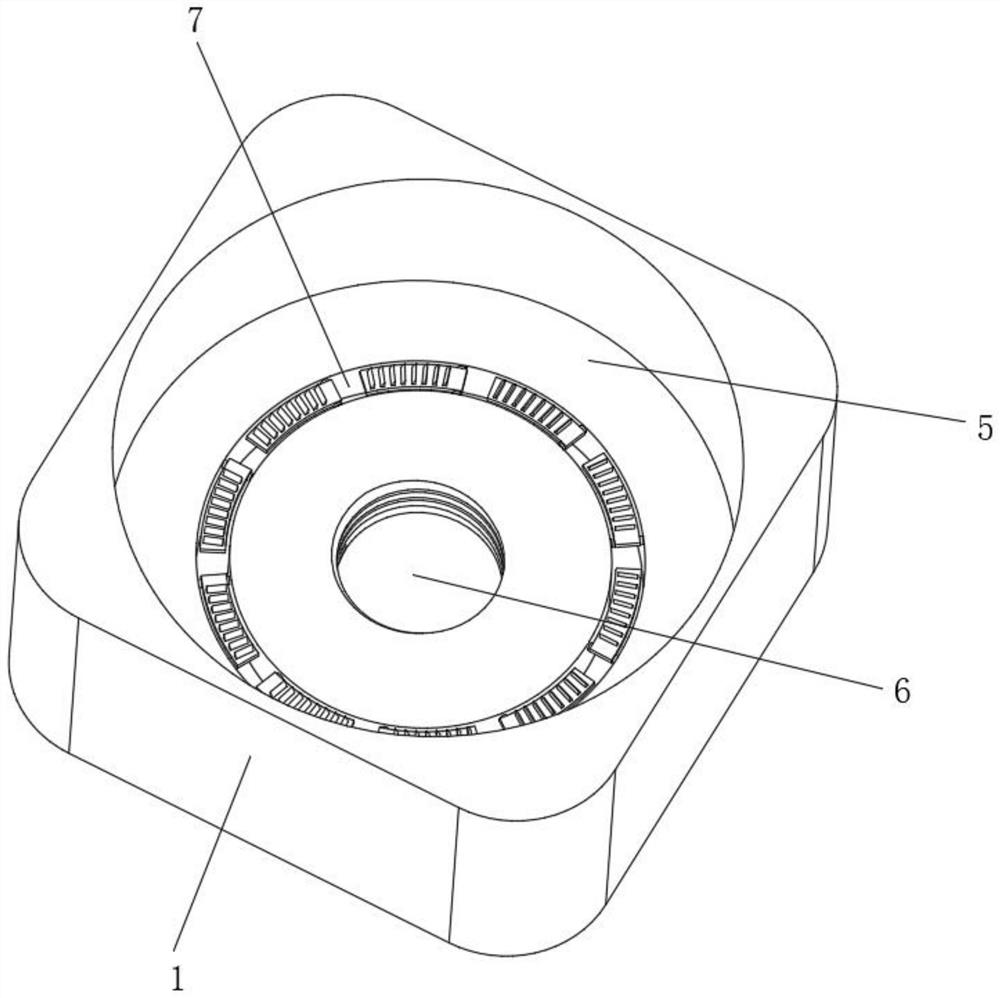

[0036] Such as Figure 1-4 As shown, the present invention provides a technical solution: a molding die for computer casing manufacturing, including a molding bottom frame 1, a concave template 2 is arranged above the molding bottom frame 1, and a molding convex mold is arranged above the concave template 2. The mold 3 is provided with a sprue mechanism 4 at the middle position of the top of the forming punch 3, and the middle position of the forming bottom frame 1 is provided with a restriction installation groove 5, and the middle position inside the restriction installation groove 5 is provided with a restriction spiral groove 6, and the restriction installation groove 5 and is located on the outside of the limiting helical groove 6, a shaker assembly 7 is arranged, and a top material assembly 8 is evenly arranged around the inside of the concave formwork 2, and the middle position of the outer bottom of the concave formwork 2 is fixedly connected with a drive screw rod 9, a...

Embodiment 2

[0038] Such as Figure 5-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a molding die used in the manufacture of computer casings. Inside, the position near the top of the rotating track 71 is rotatably connected with a movable pendulum plate 72 , and the surface of the top of the movable pendulum plate 72 is fixedly connected with a shaking protrusion 73 . Avoid the outward separation of the mold when it rotates, and ensure the relative stability of the mold rotation.

[0039]The inside of the rotating track 71 slides correspondingly with the movable slider 10 , and the shaking protrusion 73 slides in contact with the surface of the mating component 11 .

[0040] The mating component 11 includes an elastic connecting rod 111 , the back end of the elastic connecting rod 111 is fixedly connected with the movable slider 10 , and the outer end of the elastic connecting rod 111 is fixedly connected with a shaker contact plate 112 . ...

Embodiment 3

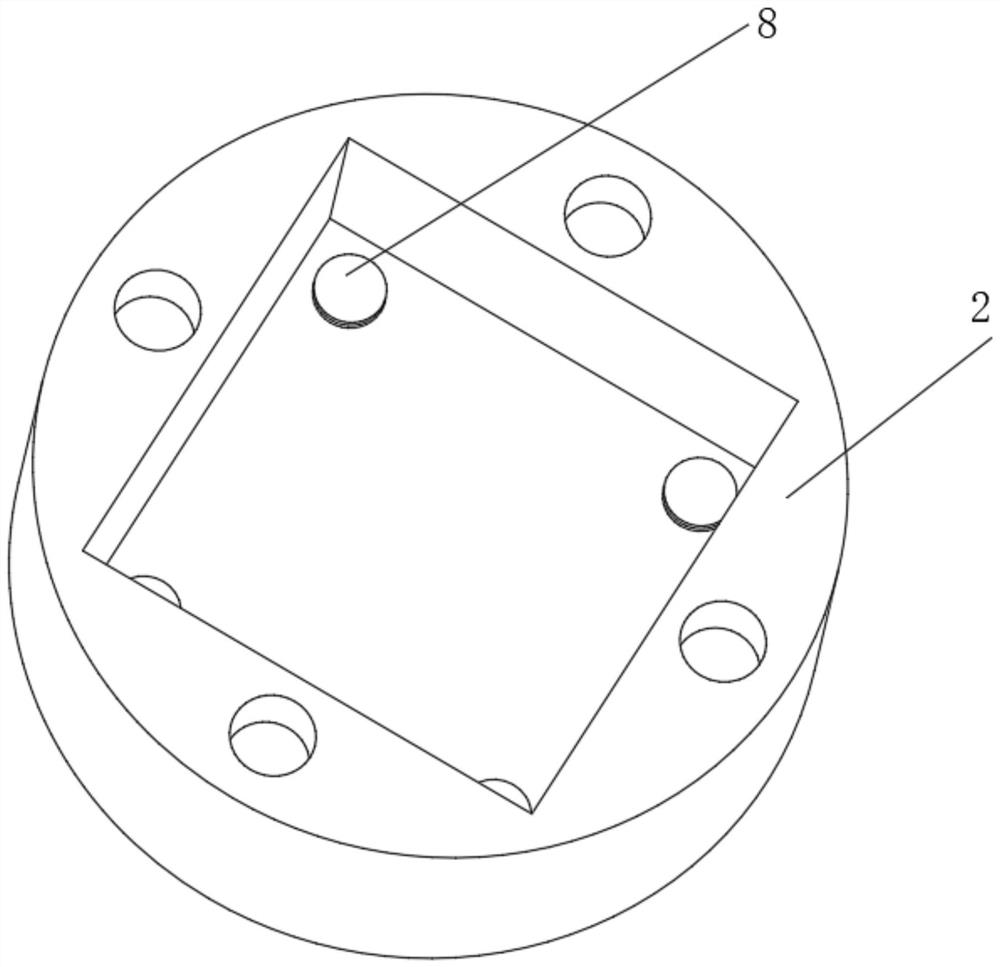

[0043] Such as Figure 7-8 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a molding die for the manufacture of computer casings, the ejector assembly 8 includes a storage pad groove 81, and the storage pad groove 81 is set Inside the concave formwork 2, a stabilizing rod 82 runs through and is slidably connected to the middle of the storage cushion groove 81, and the top of the stable plunger 82 is fixedly connected with a material-removing backing plate 83, and the material-removing backing plate 83 is connected to the top of the storage cushion groove 81. Sealed fit set.

[0044] A sealed air bag 84 is fixedly connected to the bottom of the stabilizing rod 82 , movable inner grooves 85 are arranged on both sides near the top of the stabilizing rod 82 , and a heat conduction block 86 is fixedly connected to the inside of the movable inner groove 85 . Ensure the stability of the mold during molding and avoid the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com