Combined type wire wrapping equipment for mechanical equipment

A technology for mechanical equipment and winding equipment, applied in the field of combined winding equipment for mechanical equipment, can solve problems such as the inability to fundamentally prevent the winding device from sliding, the inability to simultaneously prevent the winding device from sliding left and right, and the disadvantage of winding efficiency. , to increase the scope of application, improve the anti-skid effect, and achieve the effect of high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

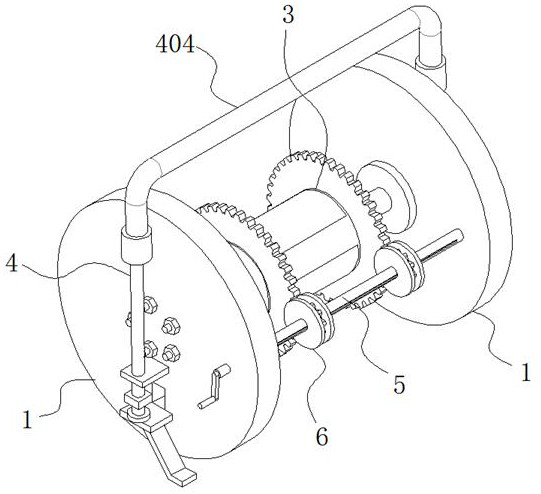

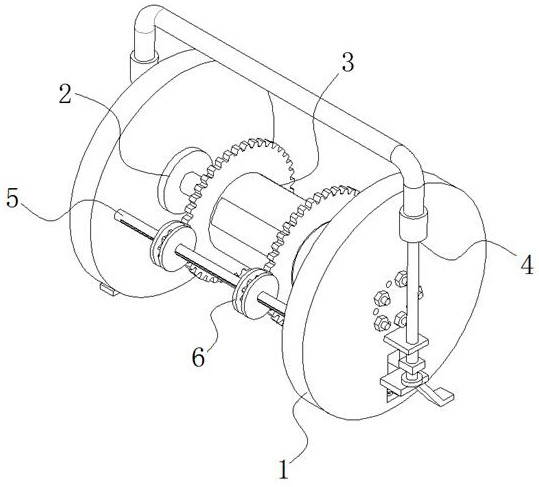

[0057] see Figure 1-16 , the present invention is a combined winding device for mechanical equipment, comprising two mounting discs 1 arranged oppositely;

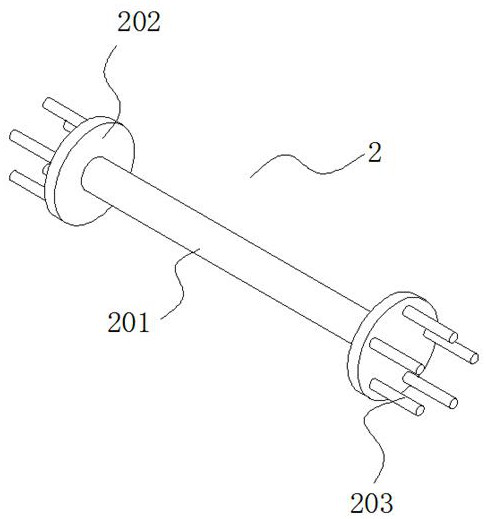

[0058] A support mechanism 2 is clamped between the two installation disks 1, which can be disassembled with the installation disk 1; the external thread of the support mechanism 2 is connected with a winding mechanism 3, and through the rotation of the winding mechanism 3, the mechanical equipment is connected with the cable Wrapped on the winding mechanism 3, the horizontal movement of the winding mechanism 3 on the support mechanism 2 can be realized by adopting the thread fit method;

[0059] A positioning plate 101 is fixedly connected to the side walls of the two mounting plates 1 away from the winding mechanism 3; the upper surface of the positioning plate 101 has a first through hole 102; the first through hole 102 is installed with a connecting component 4;

[0060] Wherein, the connecting assembly 4 includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com