A fiber optic collimator and to packaging alignment device

A technology for aligning devices and collimators, applied to instruments, optics, light guides, etc., can solve the problems of difficult operation and low efficiency, and achieve the effect of simple operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

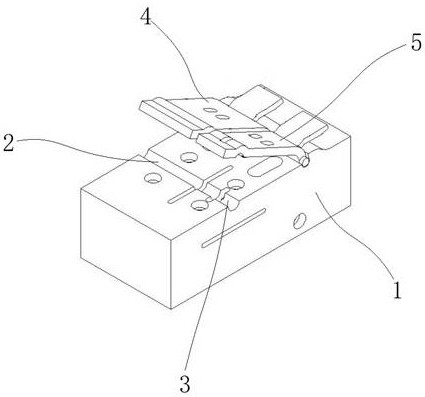

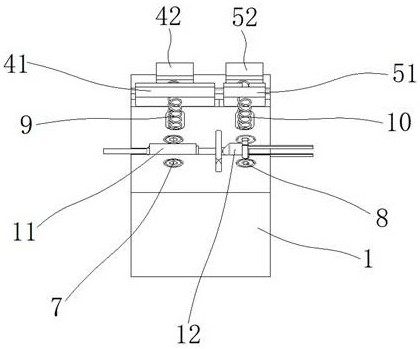

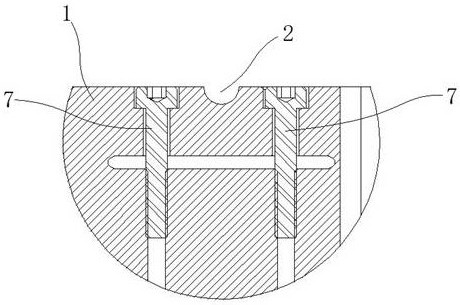

[0045] This embodiment provides a specific implementation of the fiber optic collimator and TO packaging alignment device, such as figure 1 and figure 2 As shown, the top surface of the base 1 is provided with a first tank body 2 and a second tank body 3, and the first tank body 2 and the second tank body 3 communicate; The first pressing structure, and the second pressing structure corresponding to the second tank body 3 . When it is necessary to test the optical fiber, first install the optical fiber in the collimator, then place the collimator in the first groove body 2, place the TO package 12 in the second groove body 3, and after aligning the positions, respectively Control the first pressing structure and the second pressing structure to press down to fix the fiber optic collimator 11 and the TO package 12. During the operation, you only need to put the fiber optic collimator 11 and the TO package 12 into the corresponding grooves respectively. The alignment between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com