Calibration method for visual mark displayed on terminal screen and vision detection system

A technology for screen display and visual acuity detection, which is applied in the fields of eye testing equipment, medical science, diagnosis, etc. It can solve the problems of consistency, error, and the size of the visual target, etc., and achieve the advantages of convenient implementation, accurate calculation, and ensuring comparability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

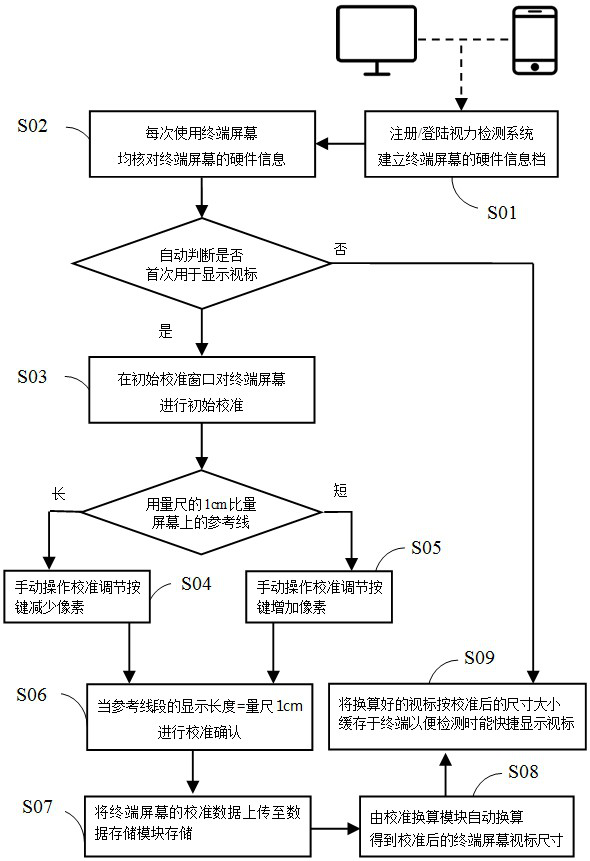

[0034] The method for calibrating the visual target displayed on the terminal screen of the present invention comprises the following steps:

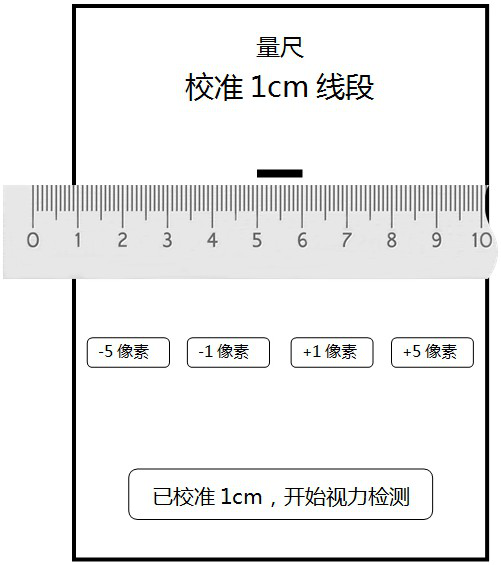

[0035] Step 1: Generate a reference line segment of specified pixels on the terminal screen, and the display length of the reference line segment at a given resolution is 1 cm.

[0036] Preferably, the specified pixel is 118.11 pixels, and the given resolution is 300dpi. Because 300dpi=300 pixels / inch, 1 inch=2.54 centimeters, so 300 pixels / inch=118.11 pixels / cm, so the display length of the reference line segment of 118.11 pixels is 1cm at the resolution of 300dpi.

[0037] Step 2: Use a physical measuring ruler to measure the length of the reference line segment on the terminal screen, and then adjust the length of the reference line segment by manually adjusting the increase or decrease of pixels, so that the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap