Synchronous working system and control method for inserting winding label printing

A technology of synchronous work and control method, applied in typewriters, printing devices, marking conductors/cables, etc., can solve problems such as easy quality problems, low work efficiency, high production costs, etc., to save offline printing efficiency and reduce matching The error probability and the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

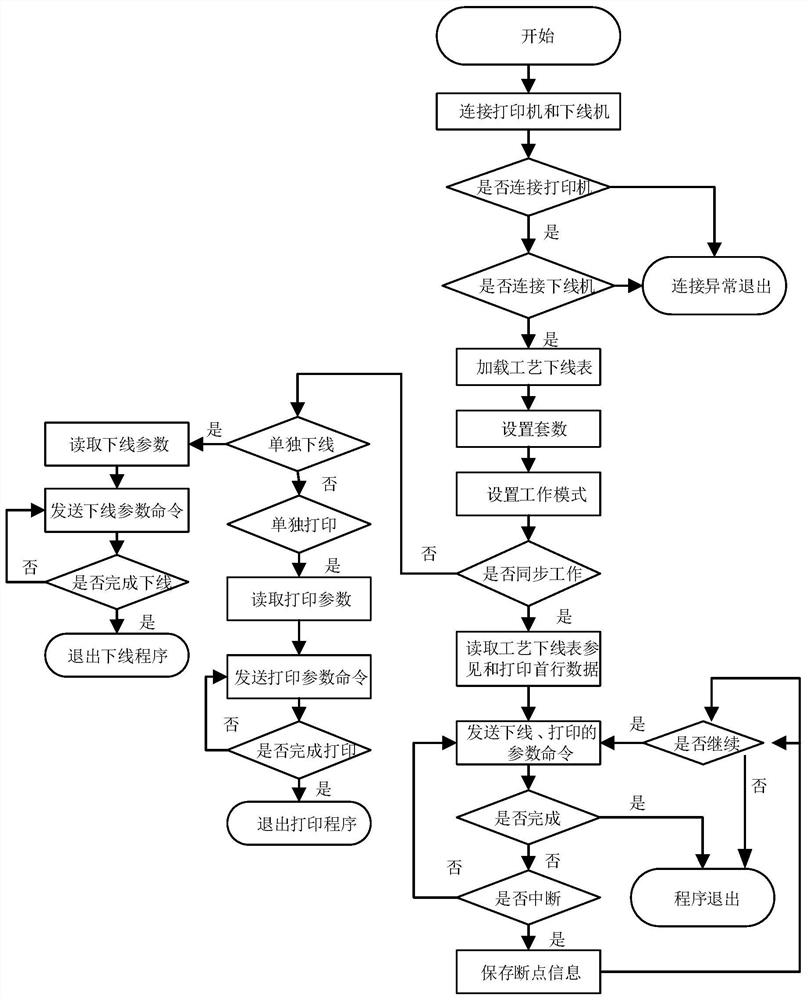

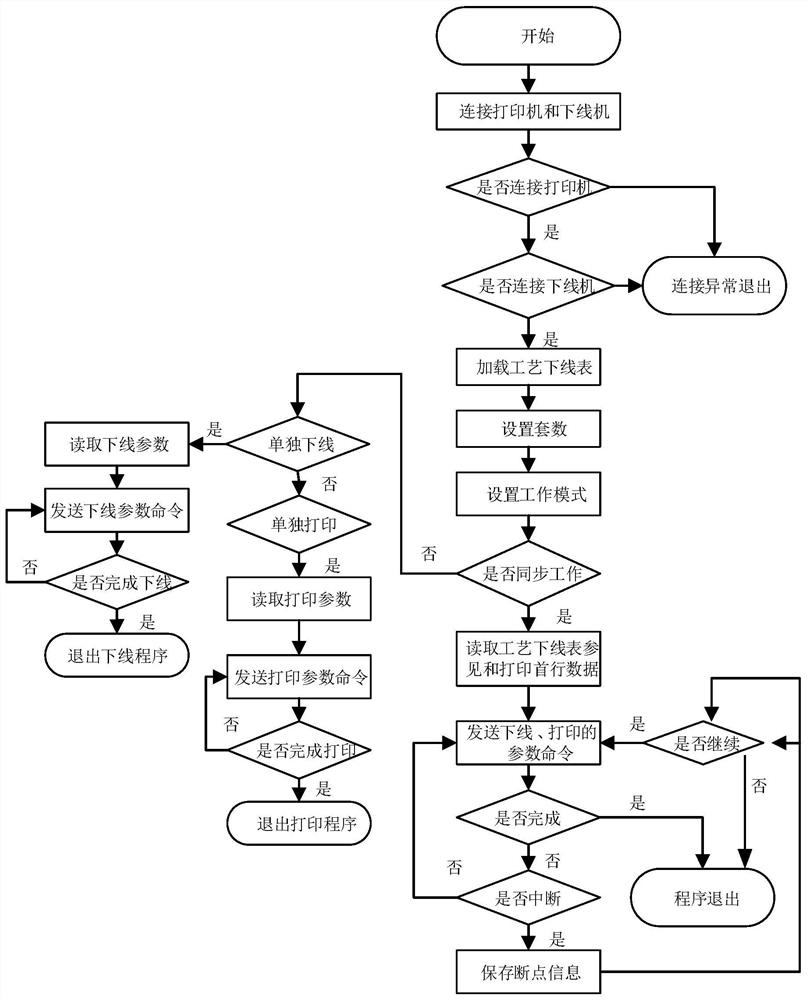

[0084] This embodiment provides a synchronous work control method for offline marking, including the following steps:

[0085] Step 1: Turn on the main controller, offline machine and label printer;

[0086] Step 2: The control module sends a connection signal to the offline machine and the label printer, and judges whether the communication between the offline machine and the label printer is normal;

[0087] If yes, go to step 3;

[0088] If not, generate a connection abnormal signal, adjust the communication connection between the off-line machine and the label printer according to the connection abnormal signal, and then proceed to step 3;

[0089] Step 3: Obtain the off-line table, set the number of sets and working mode, and judge whether to synchronize off-line and label printing;

[0090] If yes, go to step 4;

[0091]If not, judge whether to go offline separately, if so, then perform separate offline, the control module sends offline information to the offline comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com