Antibacterial fabric and antibacterial fabric processing method and process

An antibacterial fabric and processing method technology, applied in the field of fabric processing, can solve the problems affecting the use effect of antibacterial fabrics and the general bacteriostatic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

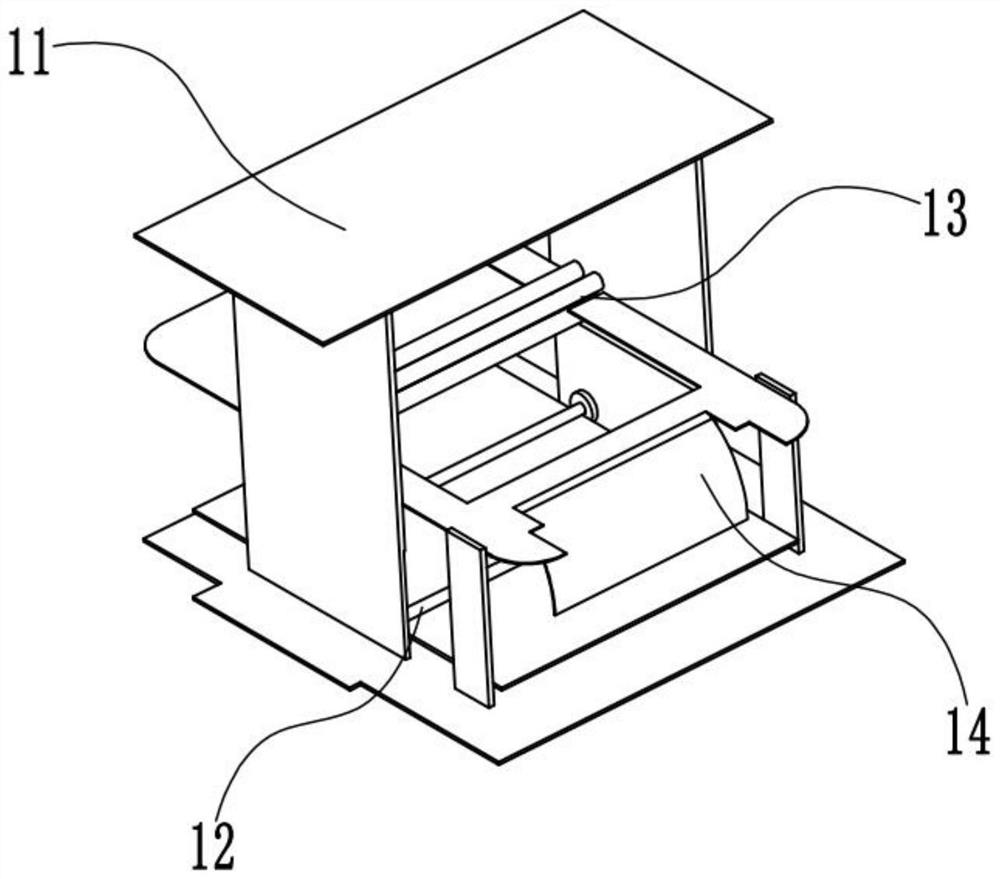

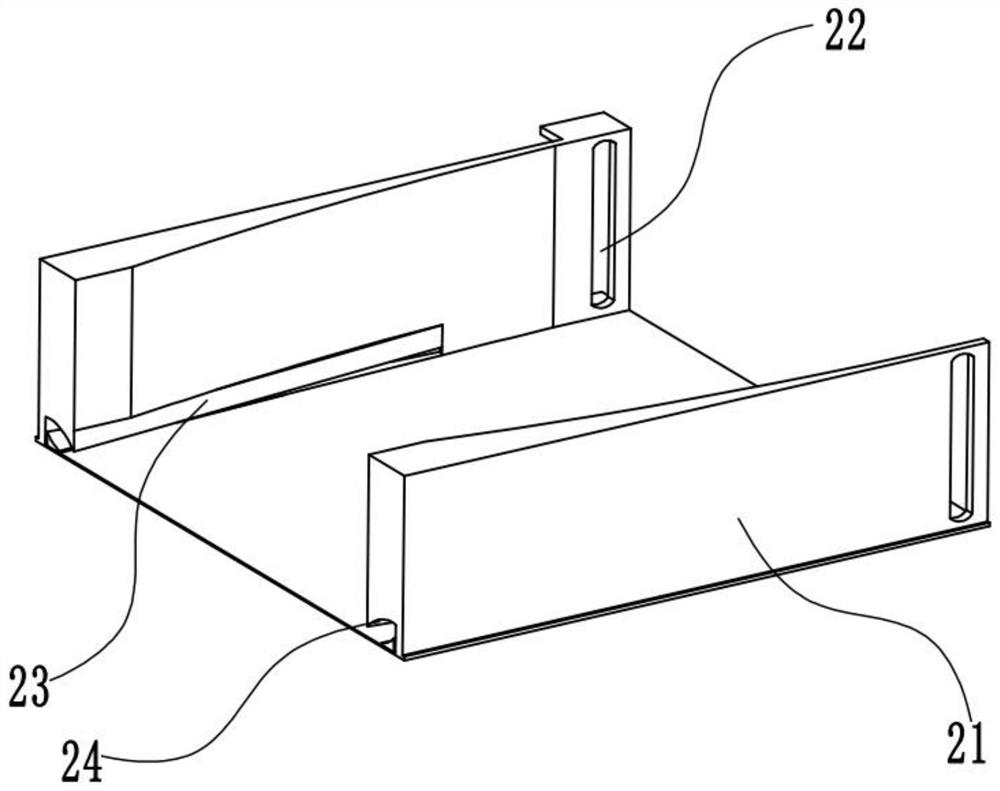

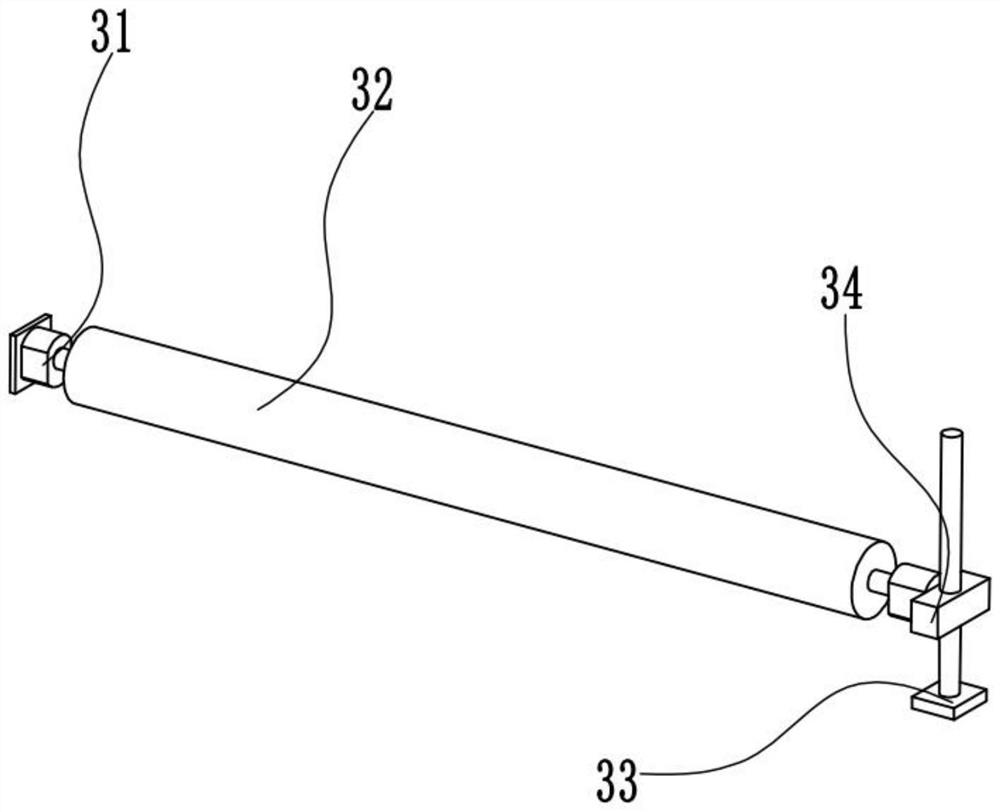

[0023] A method for processing an antibacterial fabric, the process comprising the following steps: Step 1: Soak the fabric in an antibacterial solution; Step 2: Set up an antibacterial fabric processing device, and wind the treated fabric on the device; Step 3: With the fabric Moving, the two ends of the fabric are automatically folded; Step 4: Press and sew the folded part of the fabric. The antibacterial fabric prepared by adopting an antibacterial fabric processing method, the content percentage of each component of the fabric is: cotton 10±2%, bamboo pulp fiber 25±5%, acrylic fiber 30±5%, flax fiber 15±2% and 20% ±2% artificial fibers. This kind of fabric has better antibacterial performance, and when the clothing or bedding made of this kind of fabric is used, it will have better antibacterial performance on the edge, so as to better prevent the corners of the clothing from carrying germs.

[0024] according to figure 2 , Figure 8 and Figure 10 Functional descript...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap