Material ex-warehouse method and material ex-warehouse system

A technology for materials and outbound orders, applied in the field of warehousing and logistics, can solve problems such as errors in outbound materials and high requirements for outbound personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The existing way of material out of the warehouse mainly relies on manpower for material identification, picking and other operations. Therefore, the outbound personnel are required to be very familiar with the relevant information of the materials and have certain outbound operation experience to prevent mistakes. However, in the actual outbound operations, there are still outbound material errors (type errors, quantity errors, etc.), which bring losses to enterprises and customers.

[0046] In order to solve the problem that the existing material delivery method has high requirements on the ability of delivery personnel and the existing delivery material errors, this embodiment provides a material delivery method. Before this method is implemented, each material needs to be stored in accordance with the predetermined storage rules, and a corresponding material identification is set for each storage location. Material identification includes information such as materia...

Embodiment 2

[0086] The material delivery system, its structure is as attached figure 1 shown. Before the system is used, each material needs to be stored in accordance with the predetermined storage rules, and a corresponding material identification is set for each storage location. Material identification includes information such as material name, material model, material specification and material label. The material label is a barcode or a two-dimensional code, which is scanned and recognized to display the material information, and at the same time make a warehouse registration.

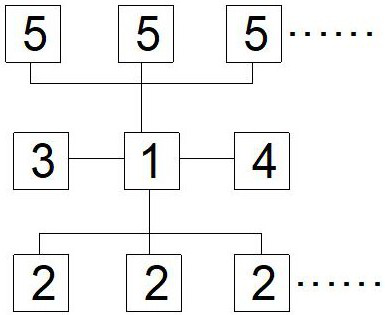

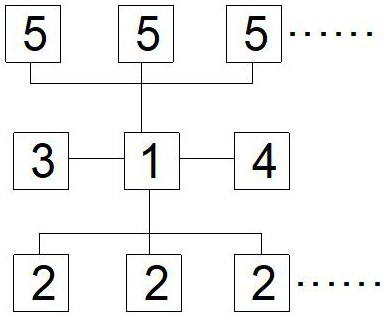

[0087] Specifically, the system includes a server 1 , a display screen 2 , a handheld terminal 3 , an output device 4 and a prompt device 5 .

[0088] Server 1, which is a PC (Computer). The server 1 has built-in control programs to realize signal processing, issuing of control commands, and the like. For example, server 1 first enters inventory information, and after receiving an order, first analyzes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com