Power distribution mounting bracket capable of improving mounting precision and mounting method

A technology for mounting brackets and installation accuracy, applied in electrical components, substation/switch layout details, etc., can solve problems such as inconvenience, component orientation and position cannot be adjusted in real time, low component installation accuracy, etc., to prevent movement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

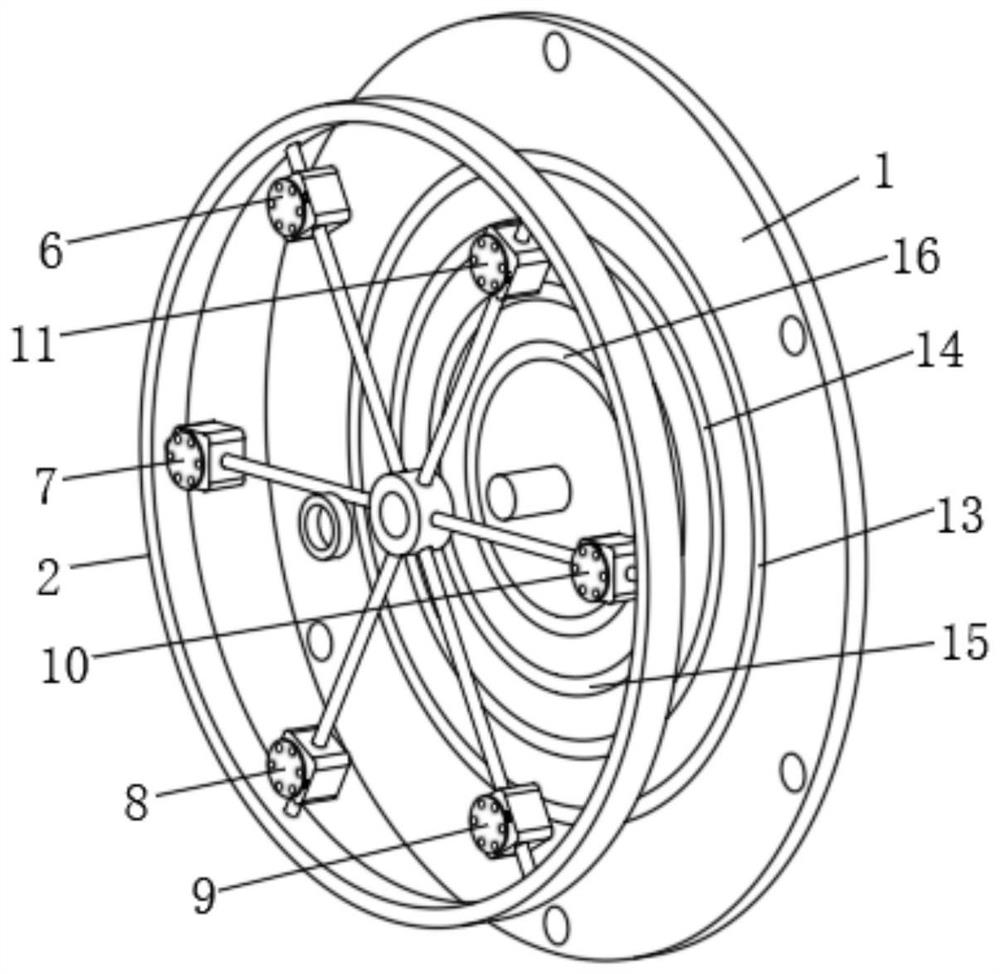

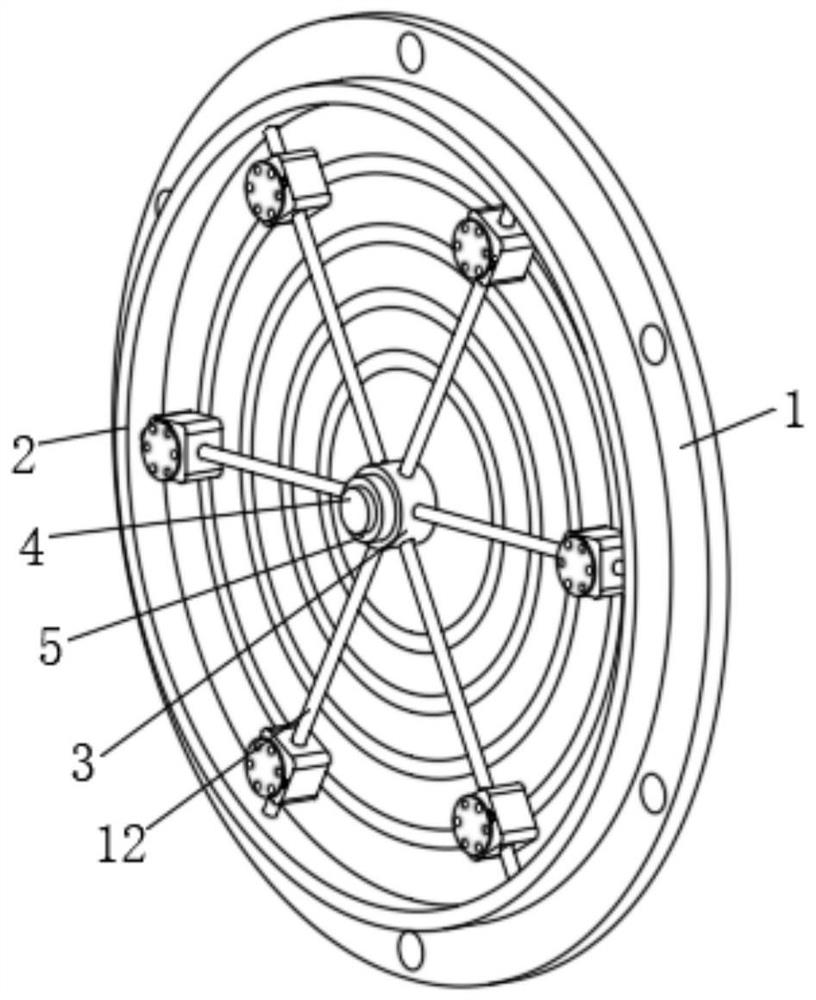

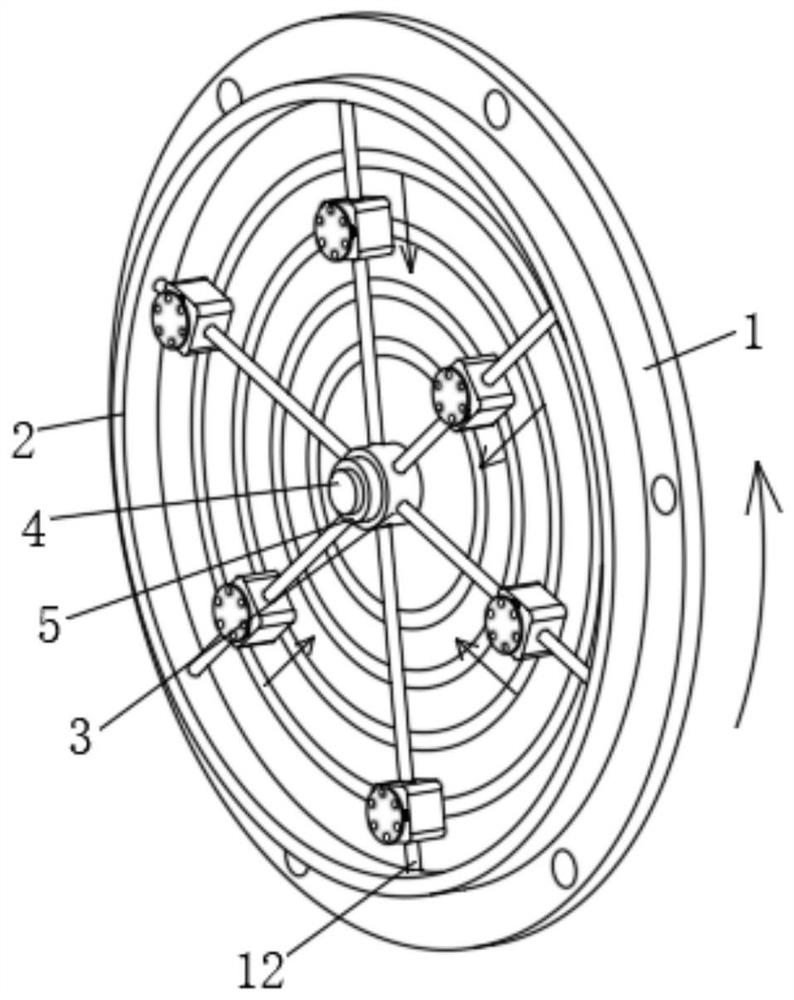

[0029] see figure 1 As shown, a power distribution installation bracket that can improve installation accuracy described in this embodiment includes a backplane 1. The difference from the prior art is that a ring frame 2 is provided on the front side of the backplane 1, and the ring frame 2 The center of the frame 2 is fixedly connected with a collar 3 through a plurality of sliding rods 12, the middle part and the front side of the backboard 1 are fixedly provided with a protruding rod 4, and the collar 3 is movably sleeved on the outer surface of the protruding rod 4;

[0030] see figure 2 As shown, the inner side of the ring frame 2 is also provided with a first mounting part 6, a second mounting part 7, a third mounting part 8, a fourth mounting part 9, a fifth mounting part 10 and a sixth mounting part 11, and The first mounting part 6 , the second mounting part 7 , the third mounting part 8 , the fourth mounting part 9 , the fifth mounting part 10 and the sixth mountin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com