Automatic inspection equipment for power cable

An automatic inspection and power cable technology, applied in the direction of electrical components, circuit devices, etc., can solve the problems that are far away from the ground, small problems cannot be known to the staff, and overhead cables cannot realize long-distance inspections, etc., to avoid jamming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

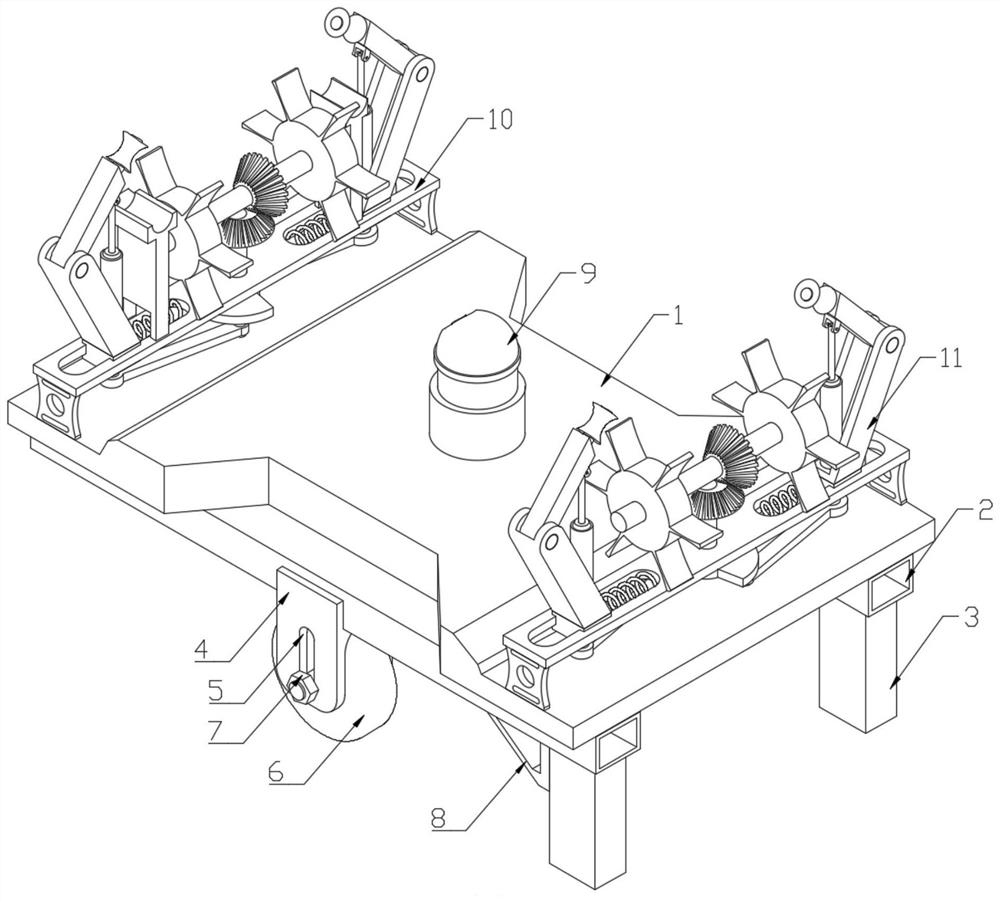

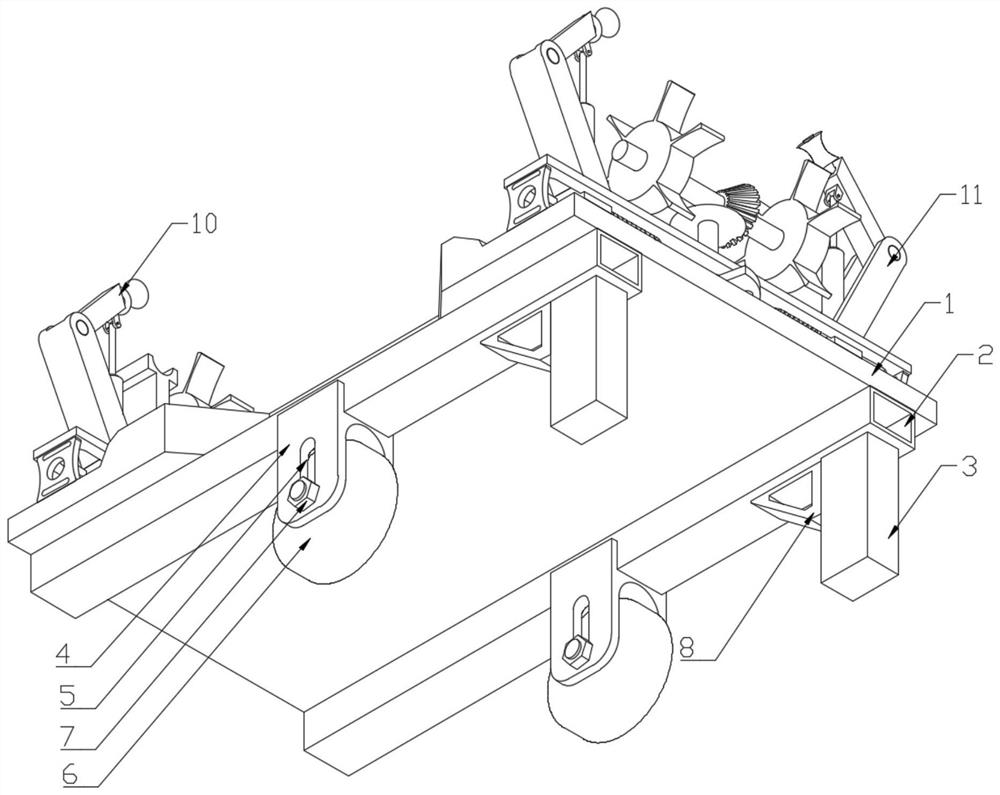

[0037] Please refer to Figure 1 to Figure 9 As shown, it shows the specific structure of the preferred embodiment of the present invention, an automatic inspection equipment for power cables, including a frame body 1, the top of the frame body 1 is provided with a fixed shell, and A control system 12 is arranged in the fixed casing, and a patrol camera 9 that can rotate 360° is arranged on the top of the fixed casing; the two ends of the frame body 1 are respectively fixedly installed with a front traveling mechanism that can walk on the cable 10 and rear running gear 11; described front running gear 10 and rear running gear 11 adopt the same structure to form;

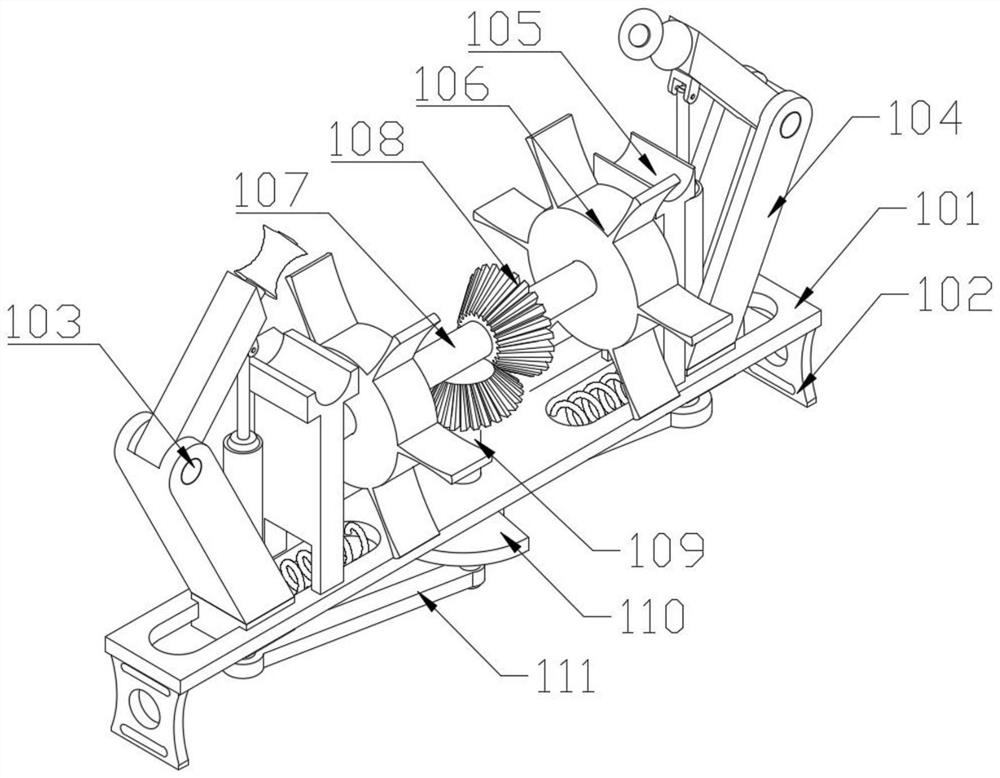

[0038]The front running mechanism 10 includes a mounting frame 101, and the bottoms at both ends of the mounting frame 101 are fixed on the frame body 1 through a bracket plate 102; The right walking assembly 104, and the inside of the left walking assembly 103 and the right walking assembly 104 are provided with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com