Fuel gas mixer of engine

A gas mixer and engine technology, which is applied to engine components, combustion engines, machines/engines, etc., can solve the problems of poor work consistency of each cylinder, different proportion of gas, poor mixing effect of gas and air, etc., to increase mixing contact Area, Enhanced Blending Effect, Effects for Good Blending Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

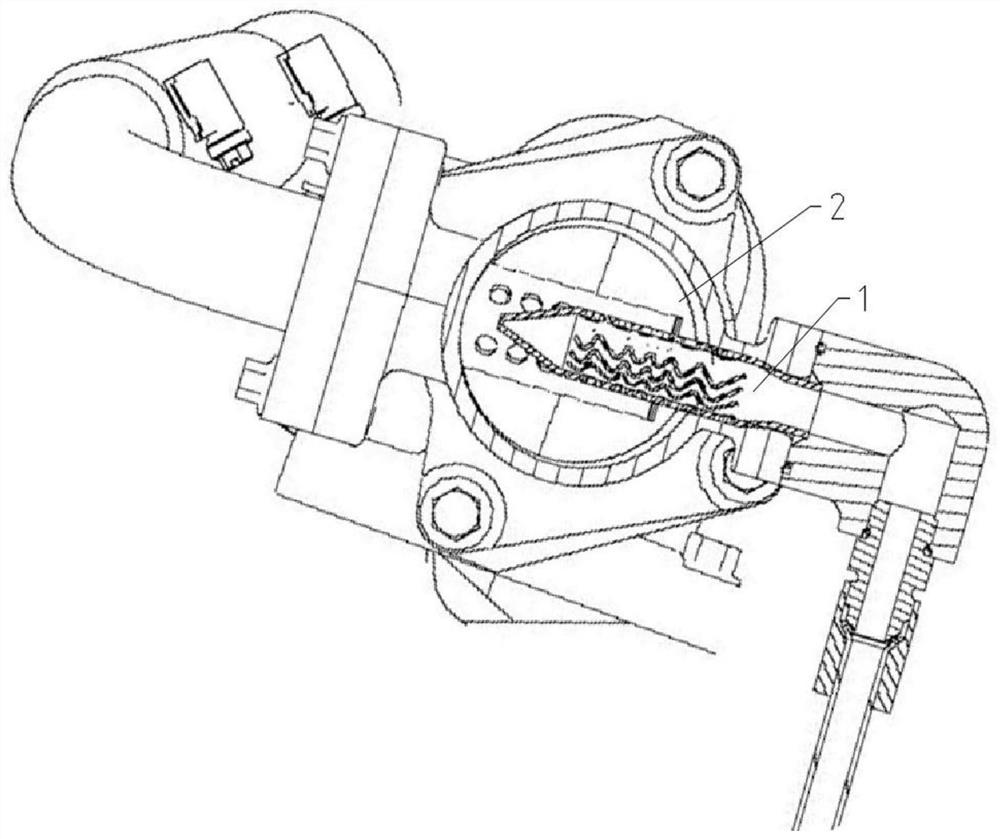

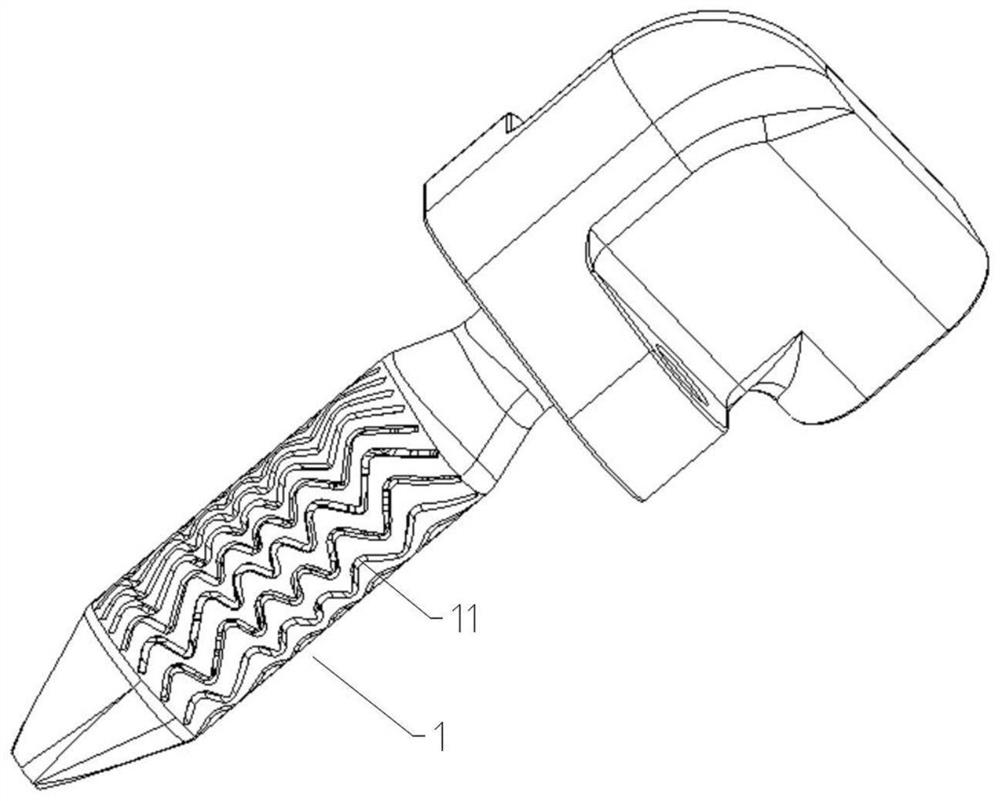

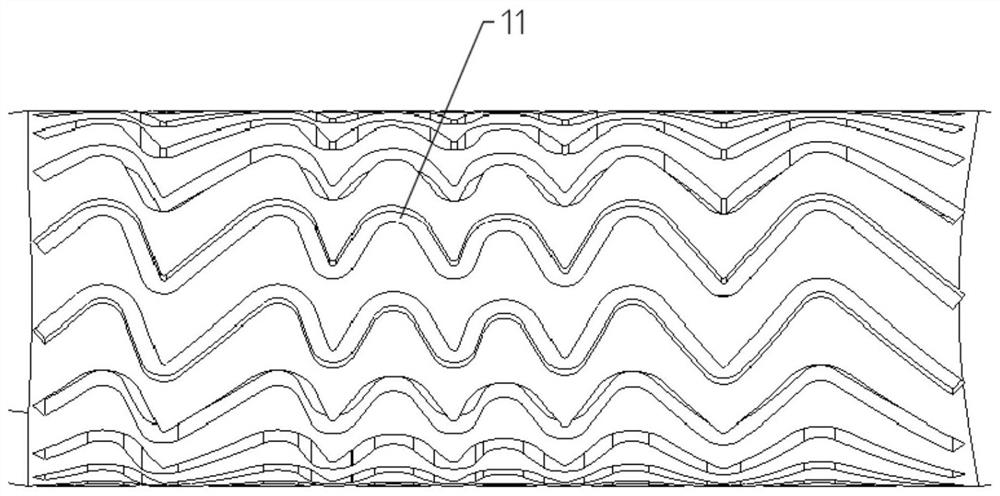

[0030] A gas mixer for an engine of the present invention comprises a mixing tube 1, which is radially inserted into the intake manifold 2 of the engine, and a plurality of gas nozzles 11 are opened on the wall of the mixing tube 1, and the gas The nozzle 11 is in the shape of a bar extending along the axial direction of the mixing tube 1 .

[0031] Specifically, as shown in the attached figure 1 , the axial direction of the mixing tube 1 is perpendicular to the axial direction of the intake manifold 2, and the gas nozzle 11 is arranged as a strip extending along the axial direction of the mixing tube 1, so that the gas ejected from the gas nozzle 11 forms a shape along the axis of the mixing tube 1. The wind wall extending in the direction, and the flow direction of the air is along the axis of the intake manifold 2, so the air directly contacts the wall surface of the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com