Confluence type desulfurization equipment and method

A technology of equipment and shell, applied in the field of converging desulfurization technology and equipment, can solve the problems of inability to achieve clean discharge, insufficient reaction and clean discharge, incomplete contact, etc., achieve good promotion value and use value, and improve gas-liquid mixing. Contact efficiency and purification efficiency, and the effect of improving contact efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

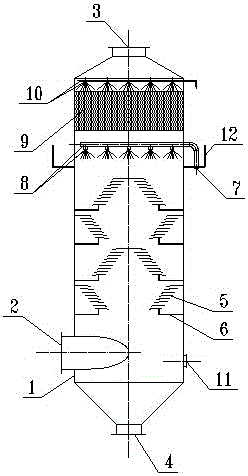

[0014] In the converging desulfurization technology and equipment of the present invention, the air inlet sends the flue gas into the casing from the tangential direction of the shell body, so that the flue gas flow enters the purification equipment and rises during the rotation process and gradually meets and flows with the washing circulating water. , this flow method eliminates the large local eddy current of the equipment, and the flue gas gradually rises during the rotation. A swirling flow gradient mixed flow plate structure is set in the shell, and the structure is gradually rotated upward according to the direction of the airflow rotation, and the airflow is separated by a multi-layer structure to ensure that large bubbles do not pass through the liquid when the gas and liquid meet. At the same time, a downward arc surface is set locally at the gas-liquid intersection to ensure that there is no gas-liquid convection and liquid cut-off phenomenon. At the same time, by co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com