High-precision device for vertically measuring outline of slender piece

A measuring device and high-precision technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems that the results are difficult to be consistent, the measurement accuracy of the shape and contour is difficult to improve, and there is no commercial instrument for the mandrel to meet the calibration or measurement needs. To achieve the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

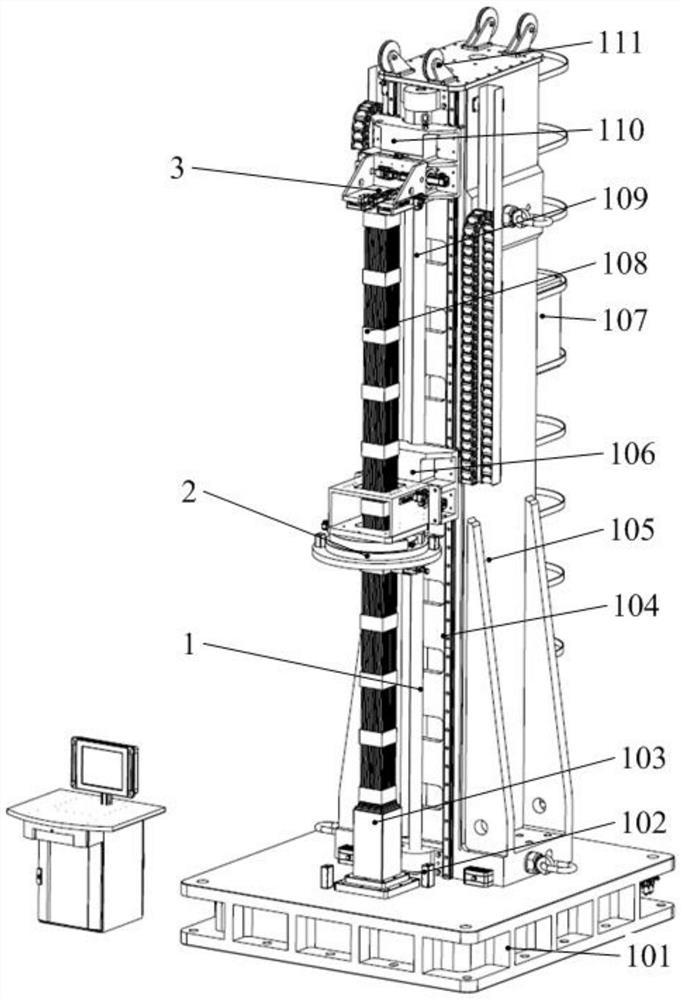

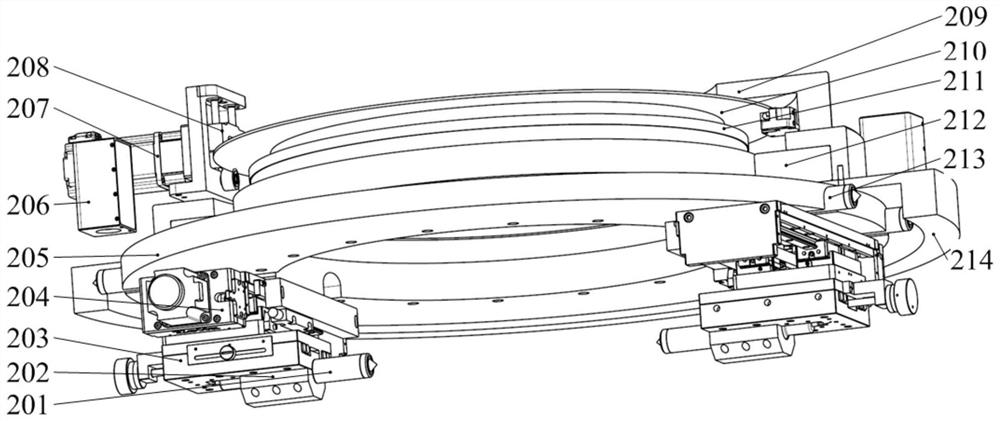

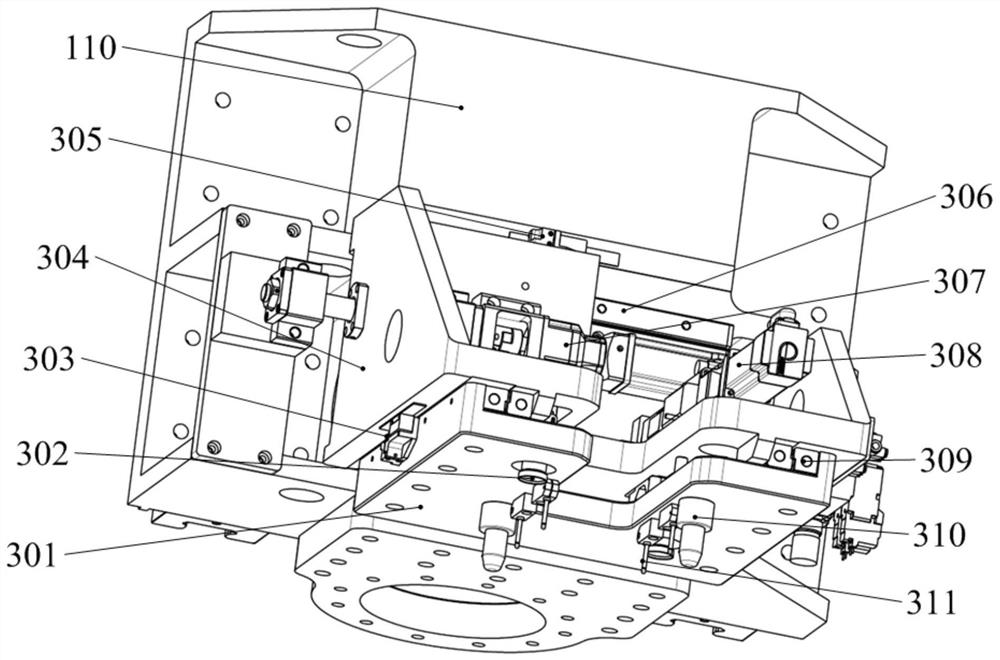

[0036] See attached figure 1 As shown, a device for vertically measuring the profile of a slender piece with high precision disclosed in this embodiment is mainly composed of four parts, one is a vertical reference guiding movement assembly 1, the other is a multi-dimensional measurement assembly 2, and the third is a rapid positioning Components 3 and 4 are motion control systems. The vertical reference guide movement assembly 1 is the basis of the measurement guidance of the entire measurement device, and is used to provide precision guide driving and collimated laser for deflection correction for the multi-size measurement assembly 2 and the rapid positioning assembly 3; The measurement component 2 is used to realize the precise measurement of the cross-sectional profile size of the measured object 108 at different vertical measurement p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap