Predictive maintenance of components used in machine automation

A technology for machines, maintenance services, applied in the field of maintenance services

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

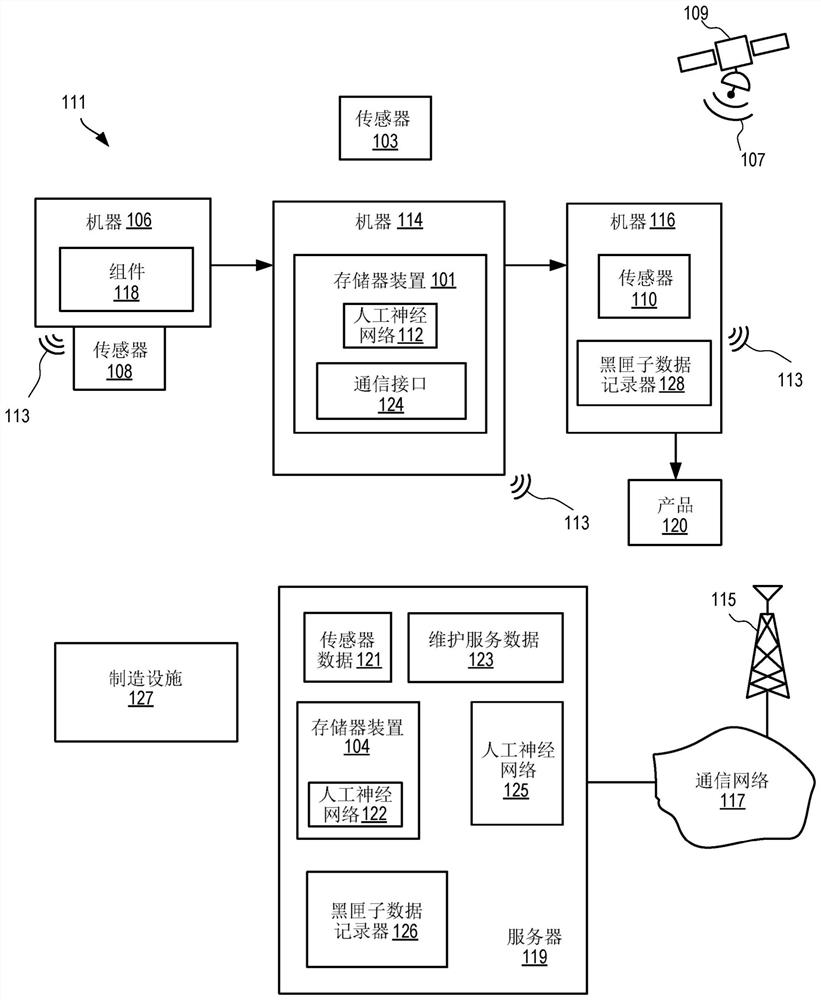

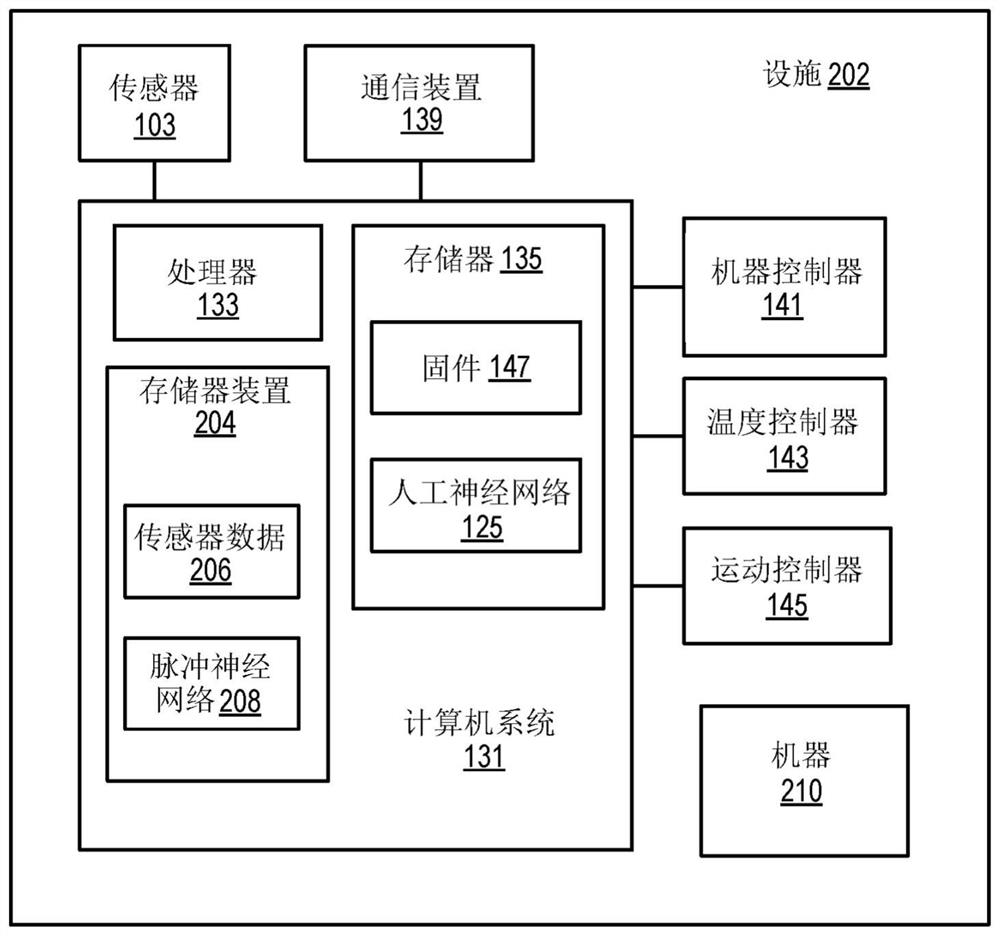

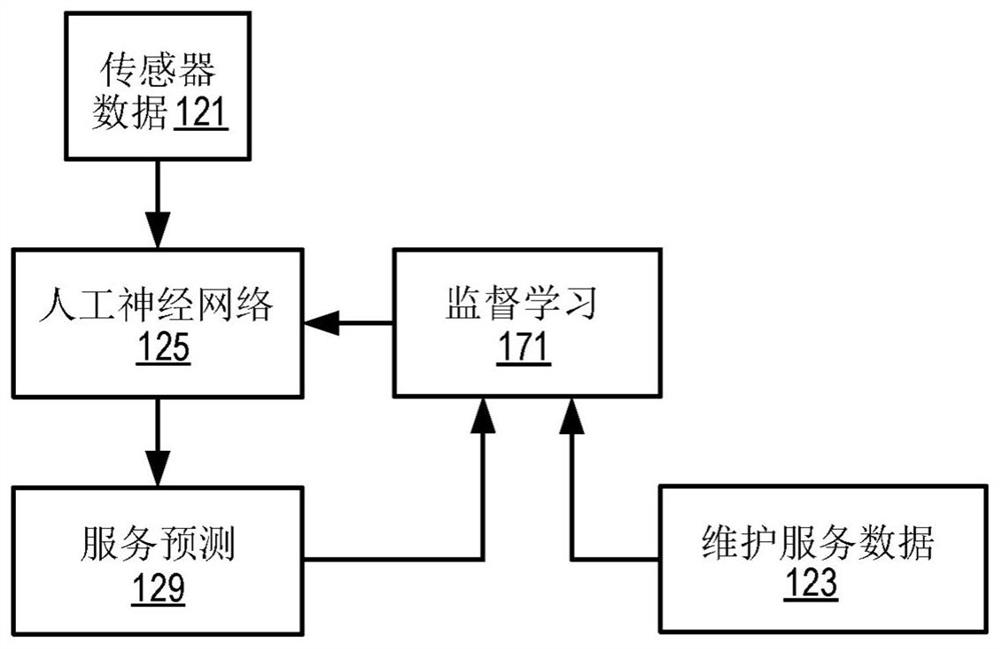

[0027] At least some embodiments below relate to predictive determination of the timing and / or type of maintenance service to be provided for a machine (eg, as used in industrial automation). In some embodiments, systems, methods, and devices are used to process collected sensor data associated with the operation of one or more machines to facilitate predictive maintenance. The collected sensor data is analyzed using one or more artificial neural networks (ANNs).

[0028] In one embodiment, the memory device collects sensor data from a machine (eg, a machine that produces a memory product for installation in a computing device by an original equipment manufacturer (OEM) customer). In one example, the memory device may be installed in or near the machine, or may be wirelessly connected to a sensor of the machine. In one example, the memory device is a solid state drive (SSD) installed in the machine. Data collected by the memory device is used to predict maintenance service f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com