High-performance surgical instrument disinfection device for surgery department

A technique for surgical instruments and sterilization devices, applied in the field of high-performance surgical instrument sterilization devices, can solve the problems of increasing operation costs, inability to completely eliminate bacteria, and infection of patient wounds, and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

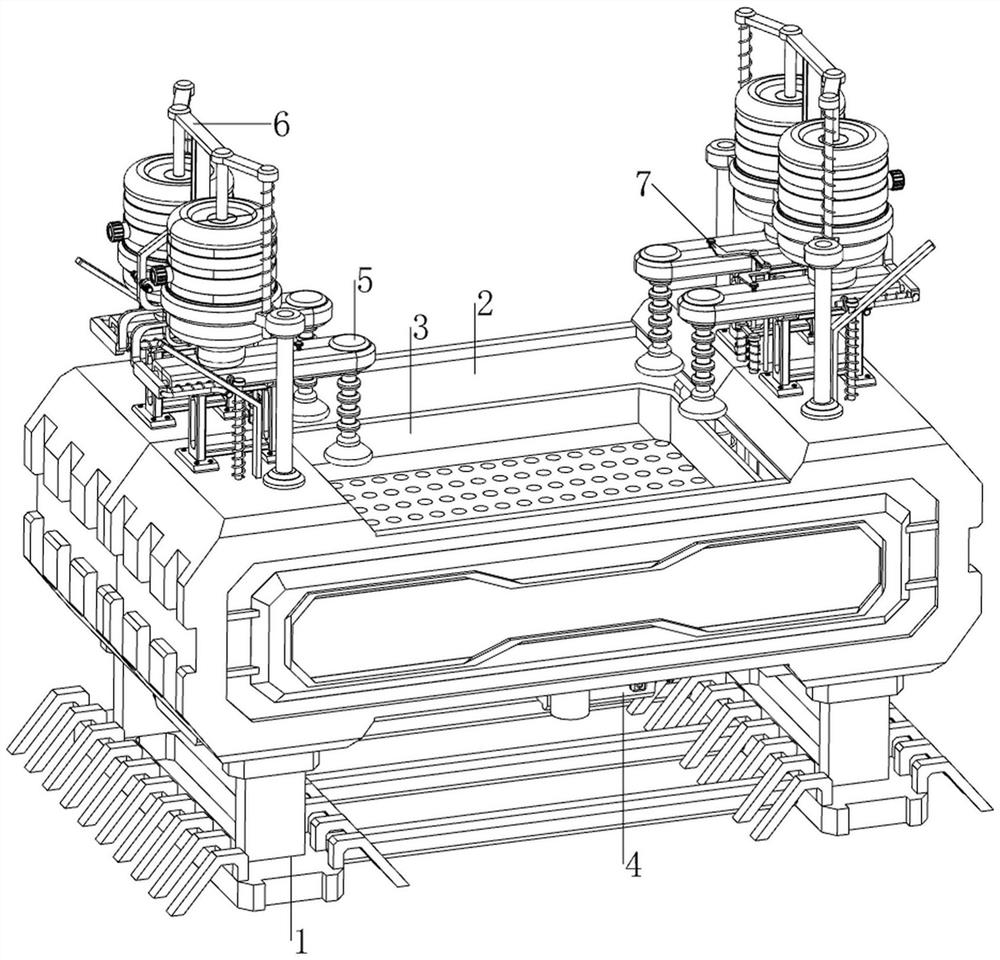

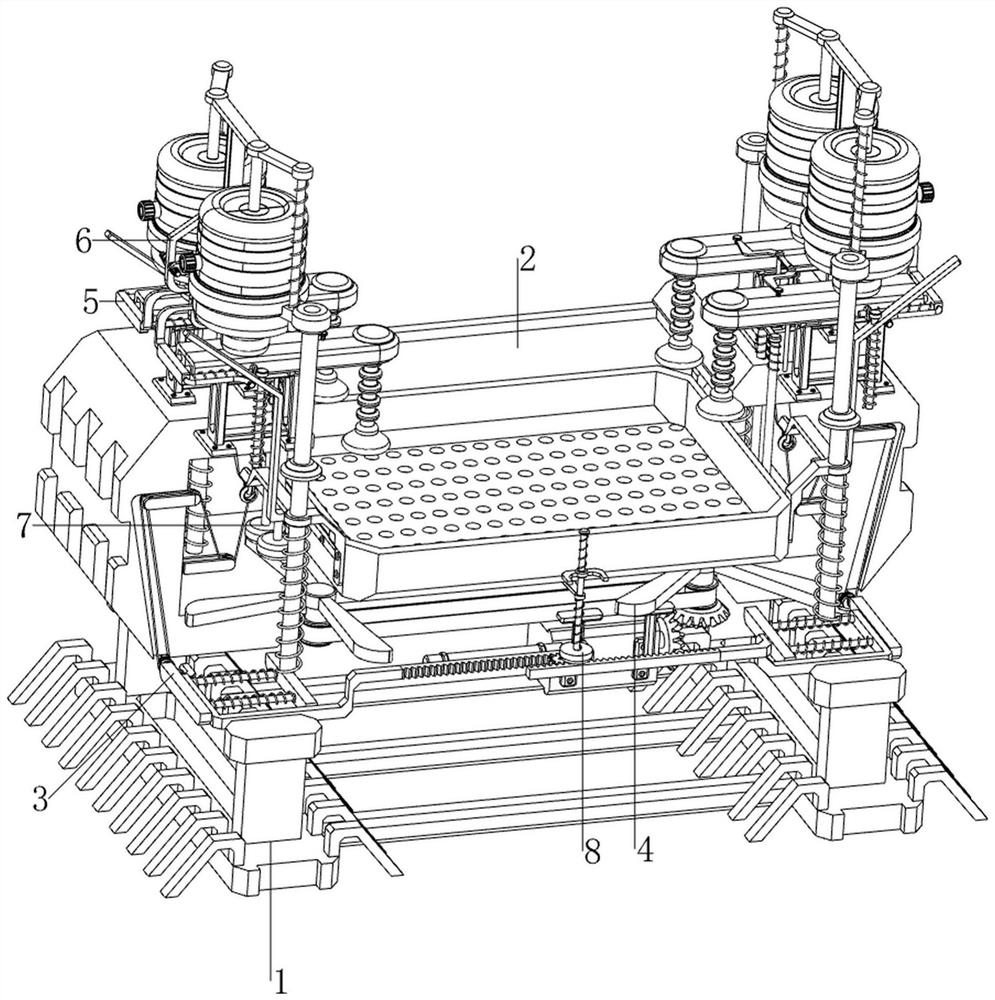

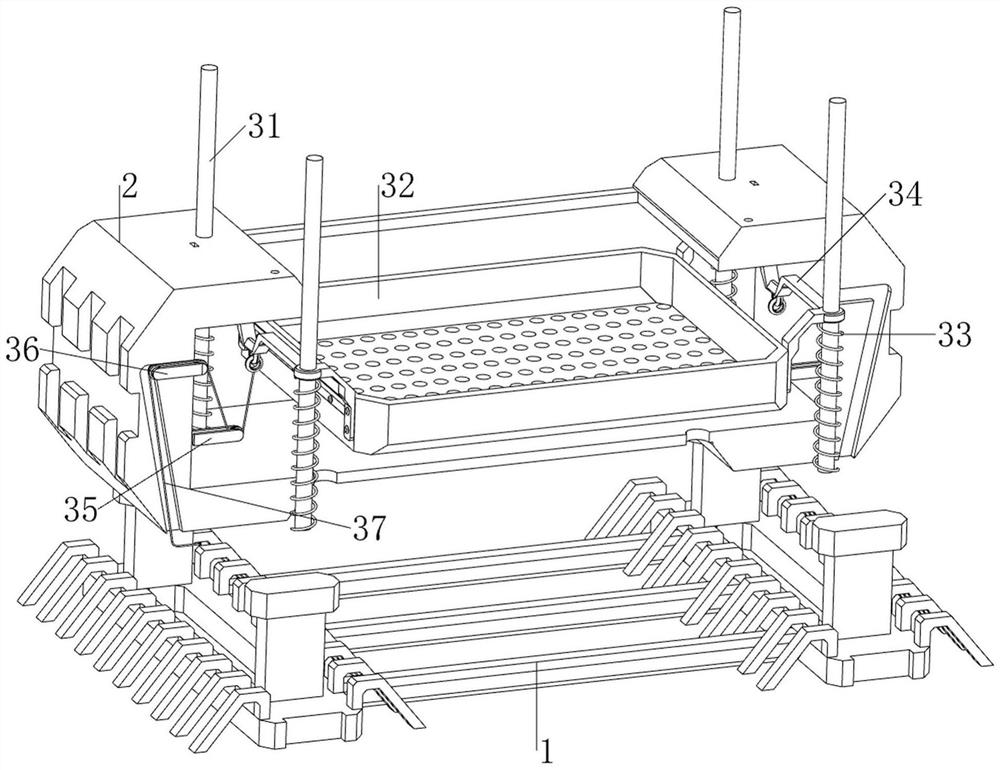

[0089] A high-performance surgical instrument disinfection device, such as Figure 1-6 As shown, it includes a support frame 1, a box body 2, a lifting mechanism 3 and a rotating mechanism 4. The top of the supporting frame 1 is provided with a box body 2, the box body 2 is provided with a lifting mechanism 3, and the box body 2 is provided with a rotating mechanism 4. .

[0090] When surgical instruments need to be sterilized, this device can be used. The staff puts the surgical instruments into the lifting mechanism 3, then pours an appropriate amount of disinfectant into the box body 2, and the staff starts the lifting mechanism 3, so that the surgical instruments move toward the The lower movement is in contact with the disinfection water, and then the rotation mechanism 4 is started. The operation of the rotation mechanism 4 will speed up the fluidity of the disinfection water, thereby realizing the comprehensive disinfection of the surgical instruments. After the disinfe...

Embodiment 2

[0096] On the basis of Example 1, such as Figure 1-2 with Figure 7-14 As shown, the opening and closing mechanism 5 is also included, and the opening and closing mechanism 5 includes a second fixed rod 51, a third spring 52, a pressing rod 53, a support block 54, a flow guide block 55, a liquid storage cylinder 56, a bottle stopper 57, Nozzle 58, the first baffle plate 59 and the fourth spring 510, the left and right sides of the top of the box body 2 are all symmetrically provided with second fixed rods 51, and the four second fixed rods 51 are all slidingly provided with pressure rods 53, The four pressure rods 53 are all slidably connected with the box body 2, and the two pressure rods 53 on the same side are all matched with the first connecting block 34 on the same side. The third spring 52 is wound on the pressure rod 53, and the third spring 52 is connected Between the box body 2 and the pressure bar 53, the left and right sides of the top of the box body 2 are symme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com