Mold

A technology of molds and snap-fit parts, which can be applied to household appliances, other household appliances, tires, etc., and can solve problems such as damage, sector deformation, and snap-fit pin deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

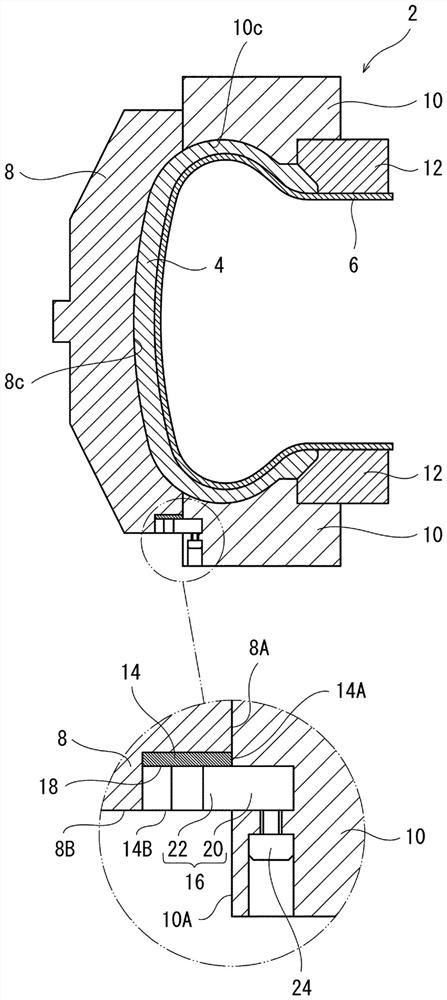

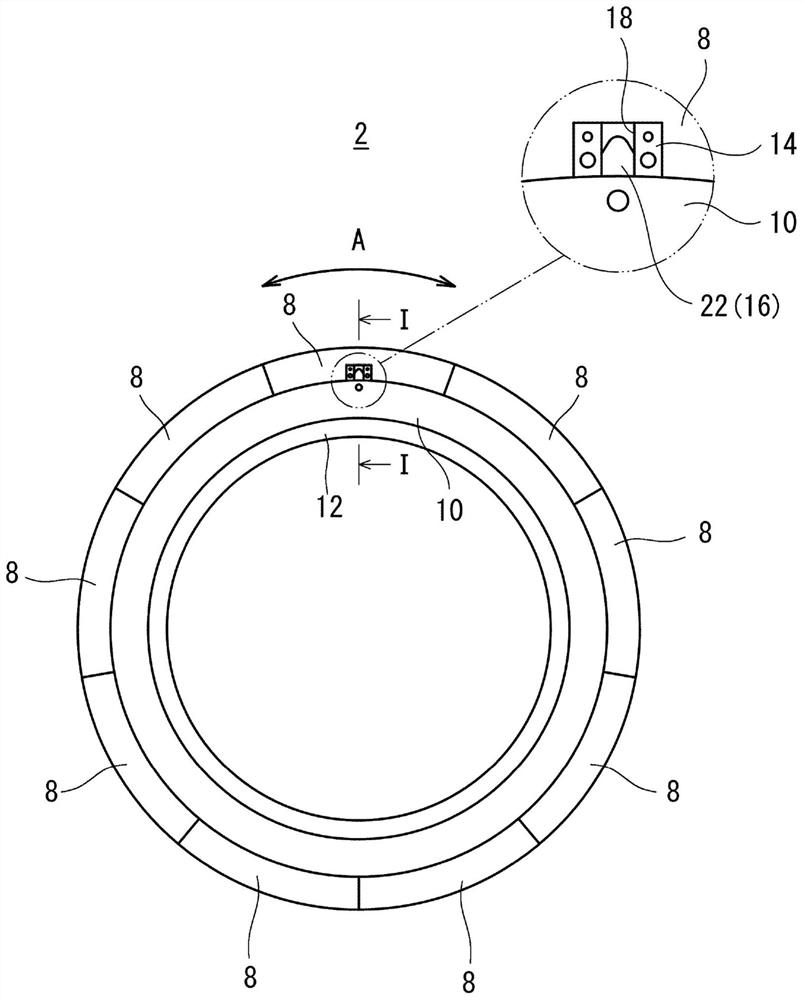

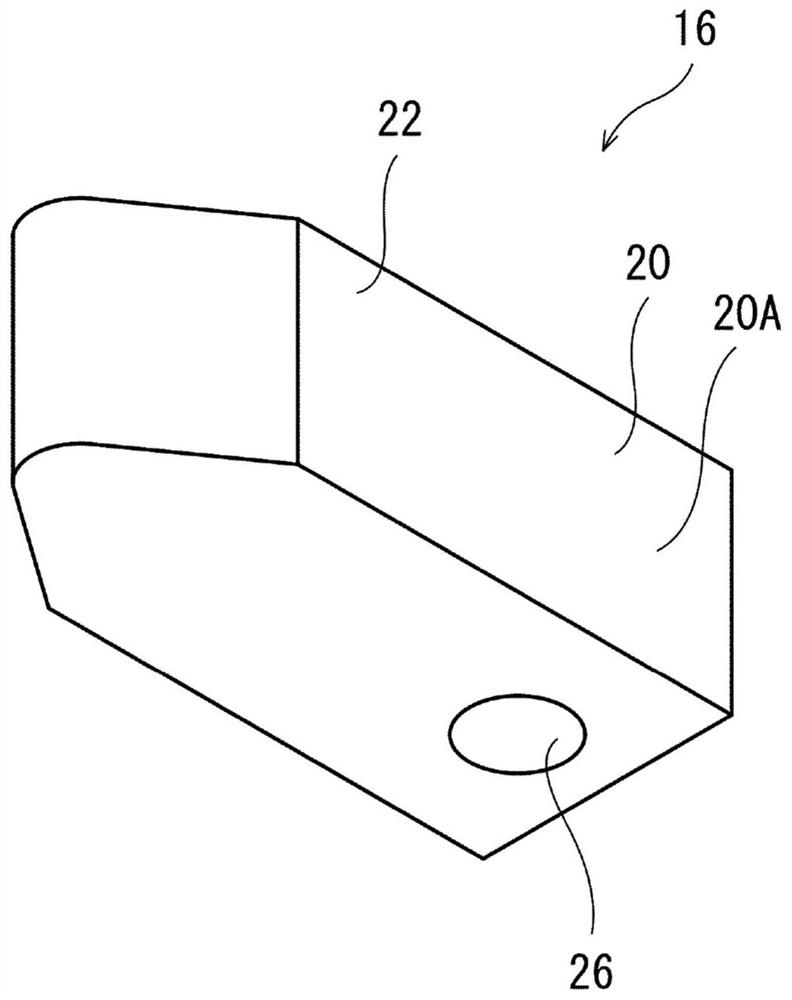

[0077] get ready figure 1 mold. The mold has 9 sectors. A first engaging part is fixed on the lower side of the first sector part arranged along the circumferential direction. In addition, a third engaging member identical to the first engaging member is fixed on the upper side of the fifth sector arranged along the circumferential direction. A second engaging piece engaged with the first engaging piece is fixed to one of the pair of side plates (the lower side plate). On the other side (upper side plate), a fourth engaging member similar to the second engaging member engaged with the third engaging member is fixed. Other parts are the same as the existing mould. Use this mold to make 1400 tires.

[0078] [Example]

[0079] 1,400 tires were manufactured in the same manner as in the examples except that the existing dies were used.

[0080] [evaluation of position shift]

[0081] 15 tires were randomly selected out of every 100 manufactured tires of the examples. For t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com