Construction method of prestressed concrete tongue-and-groove seam

A construction method and prestressing technology, applied in bridge parts, erection/assembly of bridges, bridge materials, etc., can solve problems such as veneer stress, safety accidents, and safety hazards, and achieve the effect of increasing integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A construction method for prestressed concrete grooved joints, comprising the following steps:

[0043] 1. Pre-buried friction ribs

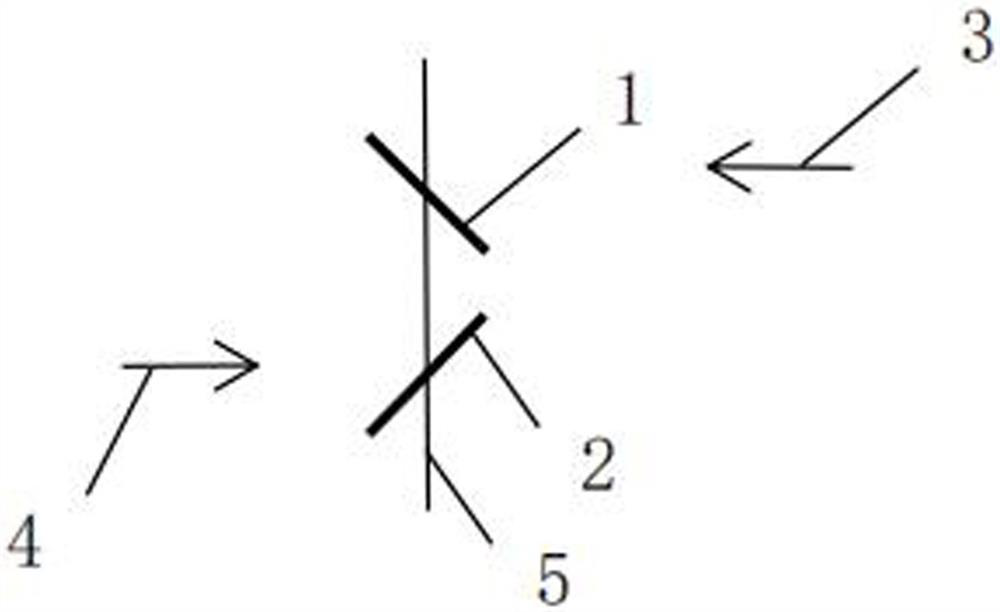

[0044] One pair is set for each section, and one pair is set for a longitudinal 300mm, such as figure 1 As shown, friction ribs A 1 and friction ribs B 2 are set, no matter whether the laterally distributed load 3 to the left or the laterally distributed load 4 to the right is applied on both sides of the interface 5 between the grooved concrete and the hollow slab concrete, the friction ribs will play a role. That is to say, the integrity of the grooved concrete and the hollow slab concrete is increased. The length of each friction rib is 400mm, the diameter is 12mm, and the angle between the horizontal line and the horizontal line is 45°.

[0045] The method, technology and quality requirements of pre-embedded friction ribs shall be implemented in accordance with the relevant provisions of (JTG / T F50-2011) "Technical Specifications for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com