Method for integrally sliding and installing a steel vestibule in a complex environment

A complex environment and overall slip technology, applied in industrial buildings, buildings, building structures, etc., can solve the problems of high hoisting height, uneconomical, high cost, reduce construction difficulty, save crane shifts, and shorten construction period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

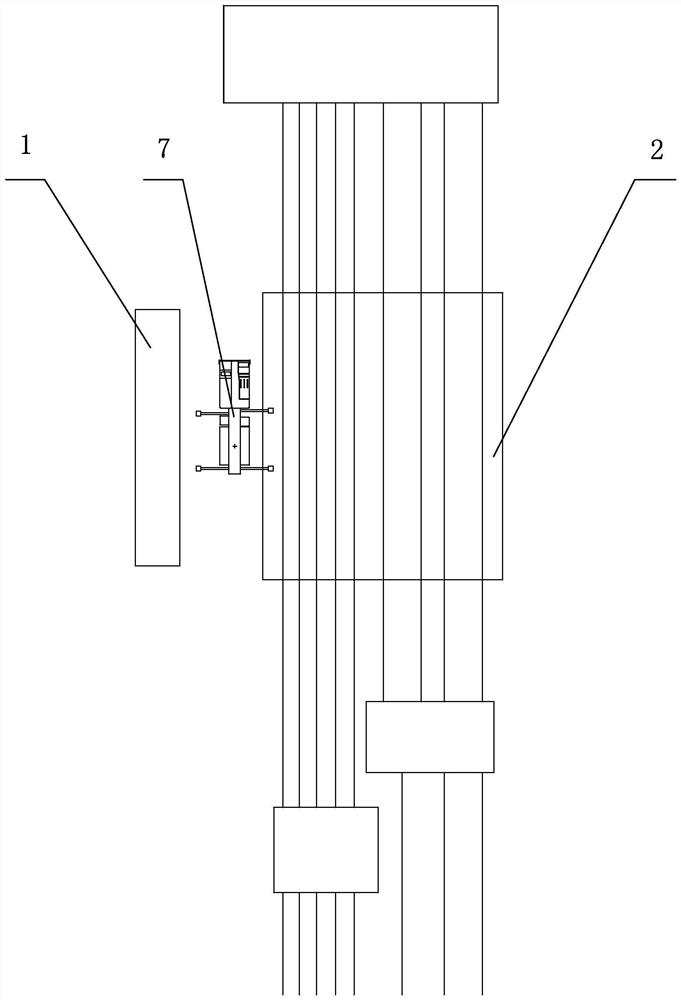

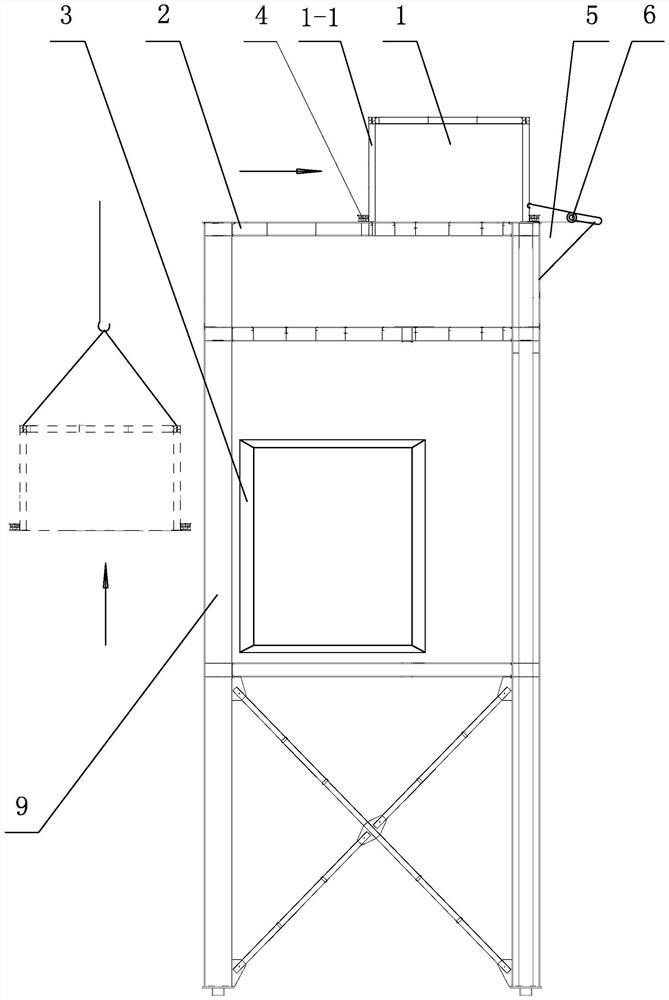

[0019] The overall sliding installation method of the steel corridor under the complex environment of the present invention is to integrally hoist the newly built corridor 1 onto the installation platform 2 built above the original corridor 3 at the production site, and use the chain hoist 6 to lift the newly built corridor 1 moves into place on the installation platform 2, and the operation steps are as follows:

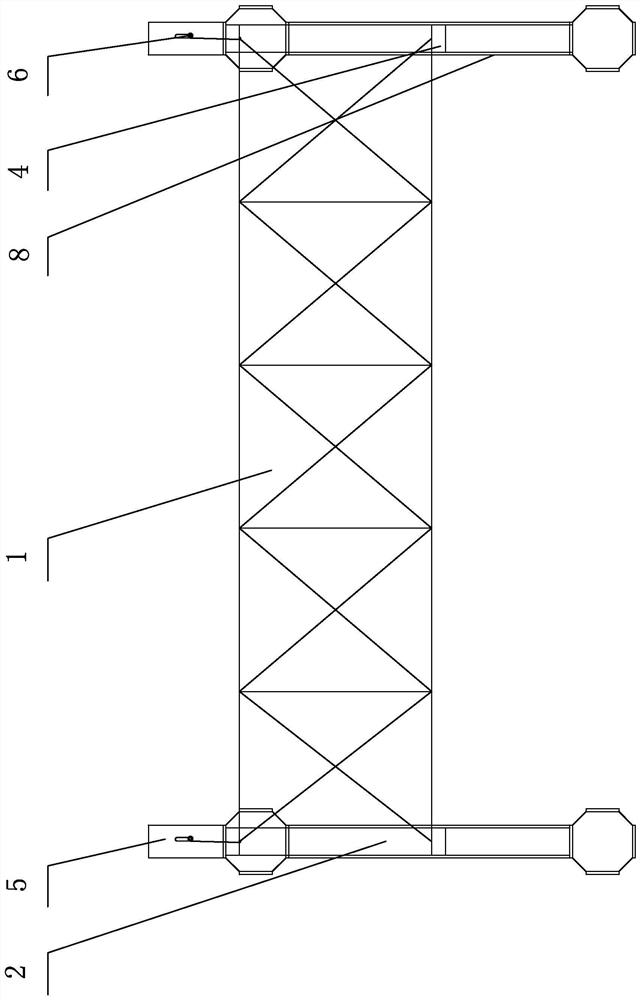

[0020] 1. Install the sliding support 4 on the bottom side of the front, rear, left and right columns 1-1 at the four corners of the new corridor 1, the installation height of the sliding support 4 is slightly lower than the bottom of the column 1-1 end, welding lifting lugs at the tops of the front, rear, left and right columns 1-1.

[0021] 2. According to the installation position of the new corridor 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com