Method and device for rapidly testing fusing characteristics of meltof filament fuse

A testing method and testing device technology, applied in measuring devices, fuse testing, instruments, etc., can solve the problems of consumables, low production efficiency, time-consuming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

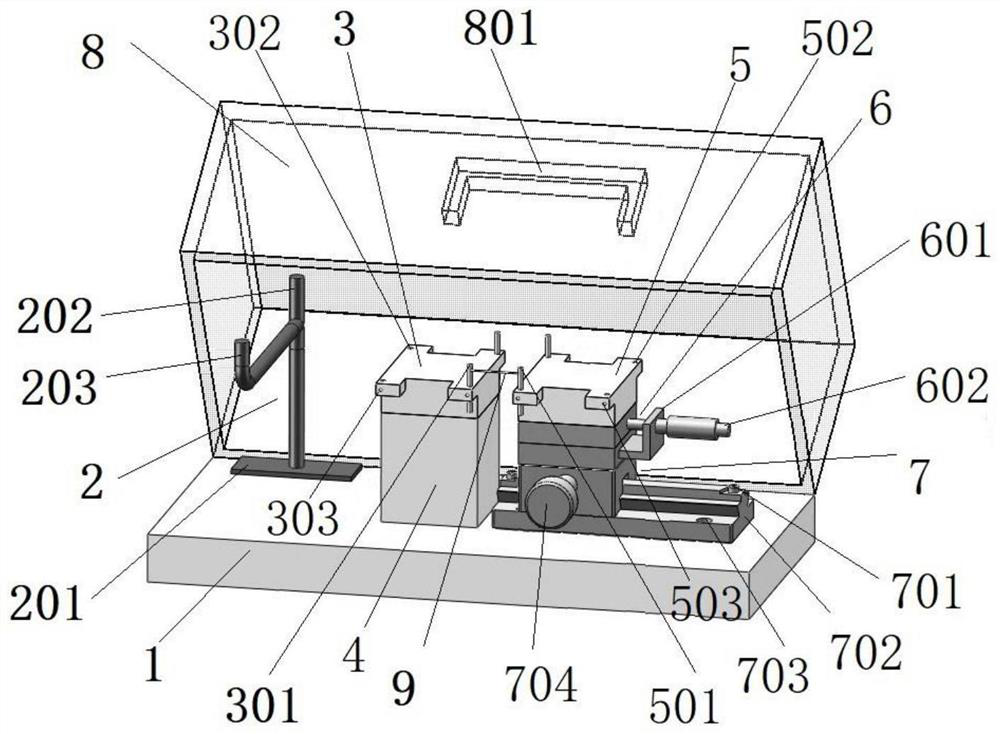

[0044] Combine below figure 1 , figure 2 The present invention is described further:

[0045] The hanger 2 includes a hanger base 201 , a hanger strut 202 , and a hanger hook 203 ; the hanger hook 203 is located at the upper end of the hanger strut 202 and is L-shaped.

[0046] The gear slide 7 includes a gear slide limit post 701, a gear slide guide rail 702, a gear slide fixing hole 703, and a gear slide X adjustment device 704, and the gear slide X adjustment device 704 is used to adjust the right clamp 5 Move left and right in the X direction.

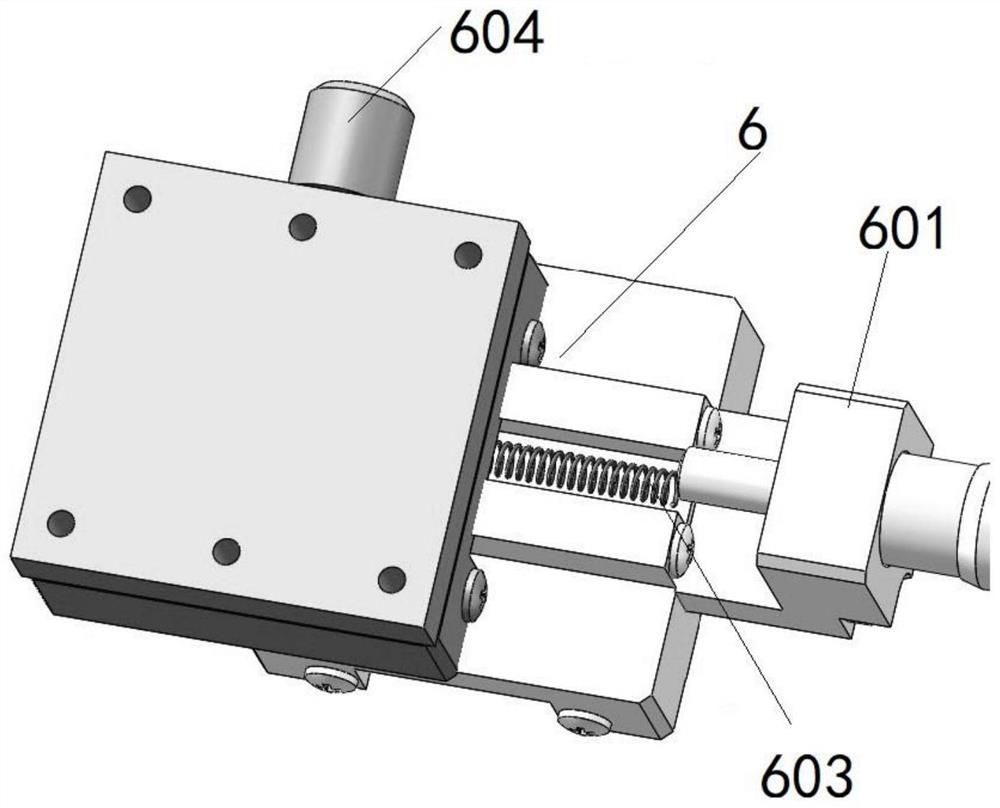

[0047] The differential slide table 6 includes a differential slide table guide rail 601, a differential slide table X adjustment device 602, a differential slide table inner tension spring 603, and a differential slide table Y adjustment device 604; the differential slide table X adjustment device 602 is used to adjust the right The fixture 5 moves left and right along the X direction, and the differential slide Y adjustment d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com